Preparation method of gradient functional ceramic

A technology of gradient function and ceramics, which is applied in the field of preparation of gradient function ceramics, can solve the problems of high processing cost, low forming efficiency, uneven green body, etc., and achieves high forming efficiency, high forming rate, high structure and dimensional accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

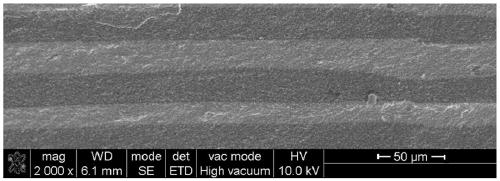

Image

Examples

Embodiment 1

[0027] This embodiment provides a functionally gradient ceramic with an eight-layer structure as a stacked structural unit and a preparation method thereof. Concrete preparation steps are as follows:

[0028] (1) Preparation of ceramic composite powder: According to the gradient structure model, the ceramic composite powder in the slurry for 3D printing the corresponding ceramic layer was prepared respectively. Using absolute ethanol as a solvent, add the components that make up the ceramic composite powder into absolute ethanol in proportion, ultrasonically disperse for 10 minutes, and then ball mill for 12 hours at a ball milling speed of 250r / min to fully mix the components. The ultrasonicated mixture was poured into a rotary evaporator, and the solvent was evaporated at 60° C., and passed through a 100-mesh sieve to obtain a ceramic composite powder.

[0029] The composition of the ceramic composite powder used to prepare each layer of ceramics in the laminated structural...

Embodiment 2

[0046] This embodiment provides a gradient function ceramic with a six-layer structure and a preparation method thereof. Concrete preparation steps are as follows:

[0047] (1) Preparation of ceramic composite powder: According to the gradient structure model, the ceramic composite powder in the slurry for 3D printing the corresponding ceramic layer was prepared respectively. Using absolute ethanol as a solvent, add the components that make up the ceramic composite powder into absolute ethanol in proportion, ultrasonically disperse for 10 minutes, and then ball mill for 12 hours at a ball milling speed of 250r / min to fully mix the components. The ultrasonicated mixture was poured into a rotary evaporator, and the solvent was evaporated at 60° C., and passed through a 100-mesh sieve to obtain a ceramic composite powder.

[0048] The composition of the ceramic composite powder used to prepare each layer of ceramics is as follows:

[0049] Ceramic composite powder of the first ...

Embodiment 3

[0063] This embodiment provides a ten-layer functionally gradient ceramic and a preparation method thereof. Concrete preparation steps are as follows:

[0064] (1) Preparation of ceramic composite powder: According to the gradient structure model, the ceramic composite powder in the slurry for 3D printing the corresponding ceramic layer was prepared respectively. Using acetone as a solvent, add the components that make up the ceramic composite powder into acetone according to the proportion, ultrasonically disperse for 10 minutes, and then ball mill for 12 hours at a ball milling speed of 250r / min, so that the components are fully mixed. The ultrasonicated mixture was poured into a rotary evaporator, and the solvent was evaporated at 60° C., and passed through a 100-mesh sieve to obtain a ceramic composite powder.

[0065] The composition of the ceramic composite powder used to prepare each layer of ceramics is as follows:

[0066] Ceramic composite powder of the first layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com