Modified wood veneer, modification method of wood veneer, wood veneer/stone plastic composite plate and preparation method of wood veneer/stone plastic composite plate

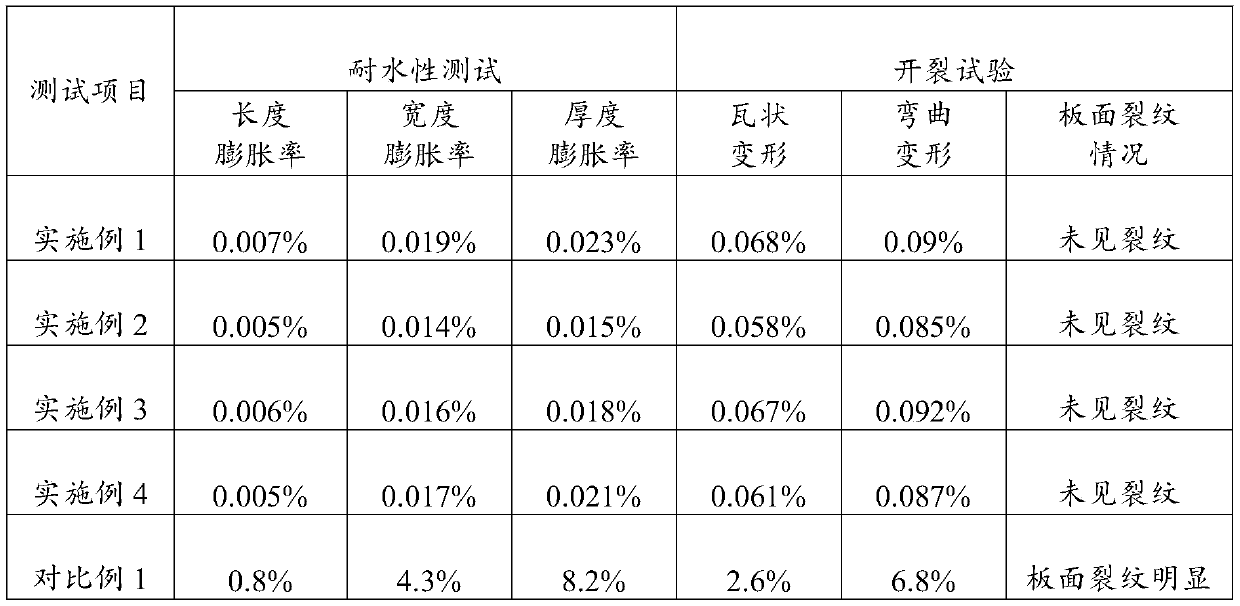

A composite board and veneer technology, which is applied in the direction of joining wooden veneers, impregnating wood, and impregnating wood, can solve the problems of large performance differences, inapplicability, limitations, etc., and achieve good water resistance and plasticity, strong water resistance, The effect of small deformability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] This embodiment is a modified veneer, the preparation method of which includes the following steps: soak the veneer with a thickness of 0.6 mm in a treatment solution with a methyl methacrylate concentration of 98%, and the treatment solution contains a mass concentration of 2% ethanol penetrating agent; transferred to pressurized tank after full soaking, at 1.2kg / m 2 Keep the pressure for 60 minutes in an inert atmosphere under 100°C, then carry out polymerization reaction in a reaction tank at 100°C, and then carry out equilibrium treatment at 25°C and an environment with a relative humidity of 25% for 7 days to complete the modification of veneer.

Embodiment 2

[0078] This embodiment is a modified veneer, the preparation method of which includes the following steps: soak the veneer with a thickness of 0.8 mm in a treatment solution with a methyl methacrylate concentration of 97%, and the treatment solution contains a mass concentration of 3% ethanol penetrating agent; transferred to pressurized tank after full soaking, at 1.3kg / m 2 Keep the pressure for 50 minutes in an inert atmosphere at 100°C, then carry out the polymerization reaction in a reaction tank at 100°C; then perform an equilibrium treatment at 22°C and a relative humidity of 40% for 6 days to complete the modification of the veneer.

Embodiment 3

[0080] The present embodiment is a modified veneer, the preparation method of which comprises the following steps: soak the veneer with a thickness of 1.0 mm in a treatment solution with a methyl methacrylate concentration of 98%, and the treatment solution contains a mass concentration of 2% ethanol penetrating agent; transferred to pressurized tank after full soaking, at 1.3kg / m 2 Keep the pressure for 70 minutes in an inert atmosphere at 100°C, then carry out the polymerization reaction in a reaction tank at 100°C; then perform an equilibrium treatment at 28°C and a relative humidity of 35% for 8 days to complete the modification of the veneer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com