High load buffer material and preparation method thereof

A cushioning material and high-load technology, applied in the field of high-load cushioning materials and their preparation, can solve the problems of reduced cushioning performance, limited application, and large weight, and achieve high compressive strength, simple preparation method, and small deformability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

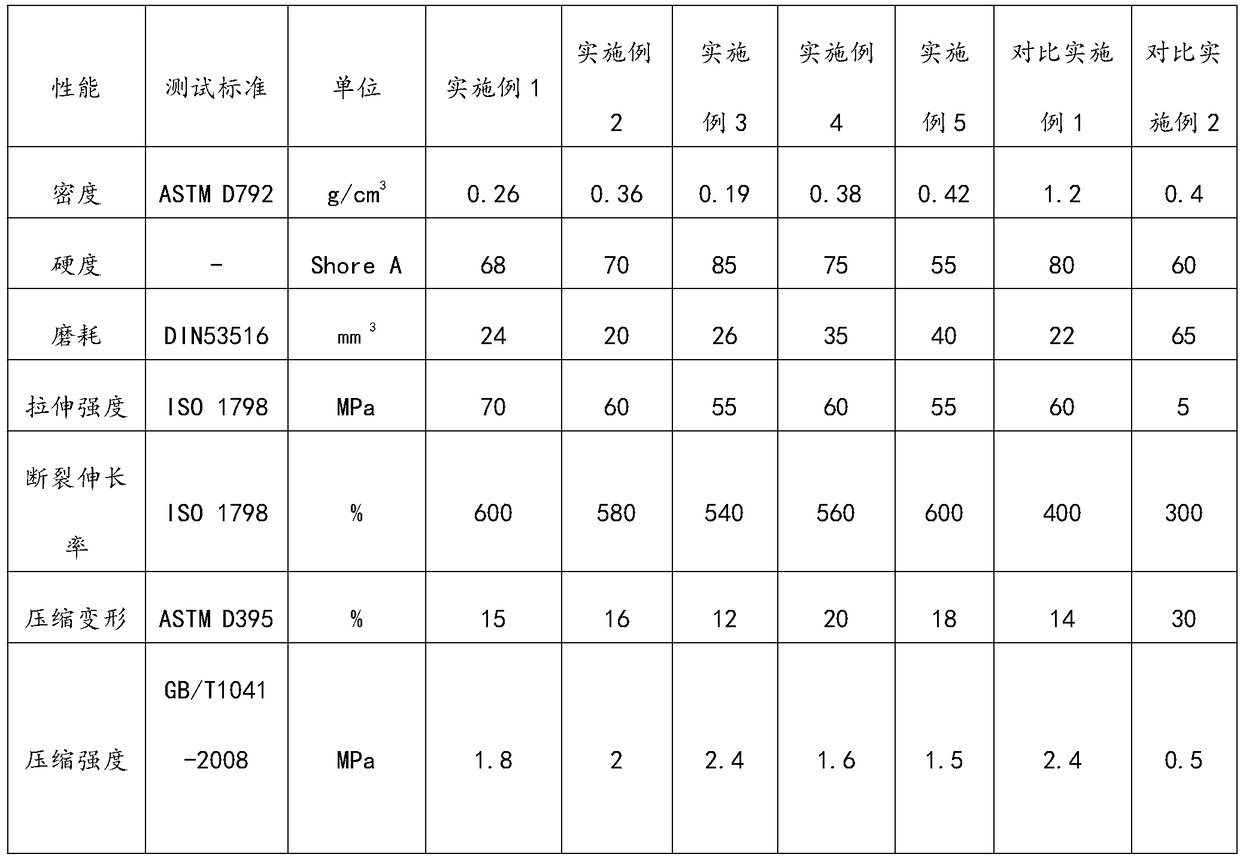

Examples

Embodiment 1

[0019] The density of 246.63kg is 0.18g / cm 3 The foamed thermoplastic polyurethane particles are mixed with 35kg of diphenylmethane diisocyanate, 60kg of 1000g / mol molecular weight polyether glycol, 10kg of ethylene glycol, 0.2kg of triethylamine, 0.5kg of silicon dioxide, After mixing evenly, fill it into the mold of the molding machine, close the mold, set the temperature to 80°C, and set the pressure to 0.6MPa. After curing for 2 minutes, cool with water at a temperature of 15°C for 5 minutes, and open the mold to obtain the cushioning material.

Embodiment 2

[0021] The density of 104.5kg is 0.32g / cm 3 The expanded thermoplastic polyester particles are mixed with 30kg of diphenylmethane diisocyanate, 65kg of 1000g / mol molecular weight polyether glycol, 8kg of ethylene glycol, 0.5kg of stannous diacetate, 1kg of zinc oxide, After mixing evenly, fill it into the mold of the molding machine, close the mold, set the temperature to 85°C, and set the pressure to 0.8MPa. After curing for 5 minutes, cool with water at a temperature of 15°C for 15 minutes, and open the mold to obtain the cushioning material.

Embodiment 3

[0023] The density of 167.4kg is 0.12g / cm 3 The foamed polypropylene particles are mixed with 38kg of toluene diisocyanate, 58kg of 1000g / mol molecular weight polyether glycol, 13kg of ethylene glycol, 0.6kg of dibutyltin dilaurate, and 2kg of talcum powder, and mix well Then fill it into the mold of the molding machine, close the mold, set the temperature at 65°C, set the pressure at 0.3MPa, cure for 8 minutes, cool with water at a temperature of 10°C for 6 minutes, and open the mold to obtain the cushioning material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com