Method for forming complete mandible prosthesis with variable-density porous structure

A porous structure and mandible technology, applied in prosthesis, bone implants, medical science, etc., can solve the problem of inability to clearly display the structure and positional relationship of the mandibular condyle, articular disc and glenoid fossa, and the inability to accurately conduct bone stress Control, unsatisfactory mandibular joint fit and other problems, to achieve the effect of improving structural accuracy and morphological accuracy, reducing prosthesis weight, and comprehensive biomechanical performance parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

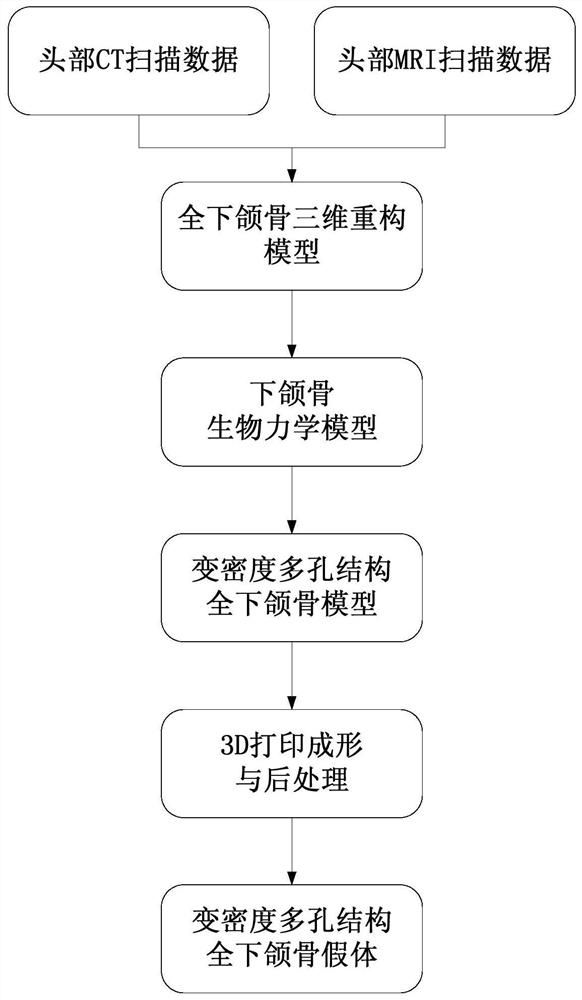

[0024] The present invention is a method for forming a full mandibular prosthesis with a variable density porous structure, (1) for the damaged mandible, respectively obtain head CT and MRI data, and respectively establish a three-dimensional model of mandibular bone structure and mandibular articular cartilage and ligaments , 3D model of muscle tissue; after 3D image fusion and mirror repair, a complete 3D reconstruction model of the full mandible was obtained; (2) According to the MRI data of the head, the attachment point and fiber direction of the mandibular muscle were obtained; On the basis of the reconstructed model, a biomechanical model of the mandible was established, and the stress distribution of the mandible was obtained through finite element analysis; (3) According to the stress distribution of the mandible in step (2), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com