Integrated electric driving power assembly

A powertrain and electric drive technology, applied in the direction of electric power devices, power devices, electric components, etc., can solve the problems of increasing the axial size of the reducer, and achieve reduced operating noise, reduced axial size, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

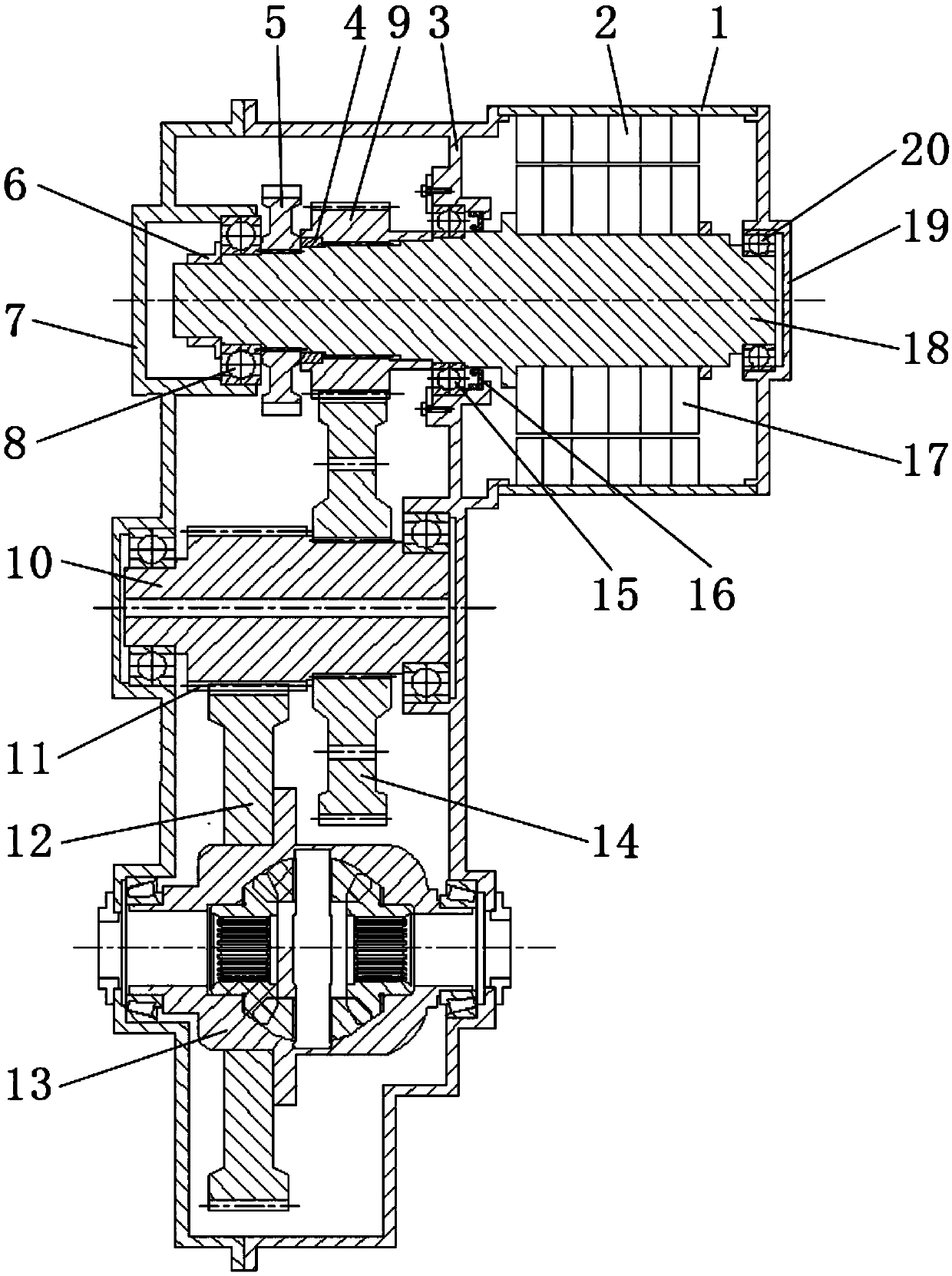

[0028] Such as figure 1 Shown is Embodiment 1 of the present invention. In this embodiment, the integrated electric drive powertrain includes a motor and a gearbox (usually a reducer), and the output shaft of the motor is integrally made with the input shaft of the gearbox to form a power The main shaft 18 of assembly is provided with parking gear 5 in the gearbox, and parking gear 5 is fixedly installed on the main shaft, promptly is installed on the main shaft 18.

[0029] Affected by the torque transmission of the gearbox (reducer), the parking torque on the main shaft is small, and the axial dimension of the parking gear 5 can be designed to be relatively small, thereby reducing the axial dimension of the powertrain. The weight of the 5 is reduced, and so is the weight of the powertrain.

[0030] The motor can be a permanent magnet motor or an excitation motor, including the rotor 17 and the stator 2 . The rotor 17 includes a rotating shaft therein, which is also part of...

Embodiment 2

[0052] This embodiment is improved on the basis of embodiment 1. In embodiment 2 of the present invention, the third gear 11 is integrally formed with the intermediate shaft 10. This design can further simplify the structure of the powertrain.

[0053] Other structures of the integrated electric drive powertrain in Embodiment 2 of the present invention are the same as those in Embodiment 1, and will not be described again here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com