Rapid manufacturing method for ship block

A manufacturing method and ship technology, applied in ship construction, ship parts, ships, etc., can solve the problems of high construction difficulty and labor intensity, difficult to control line reliability, long construction period, etc., and achieve overall accuracy and line control. Improve reliability, avoid harsh environments and high-intensity labor, and reduce difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

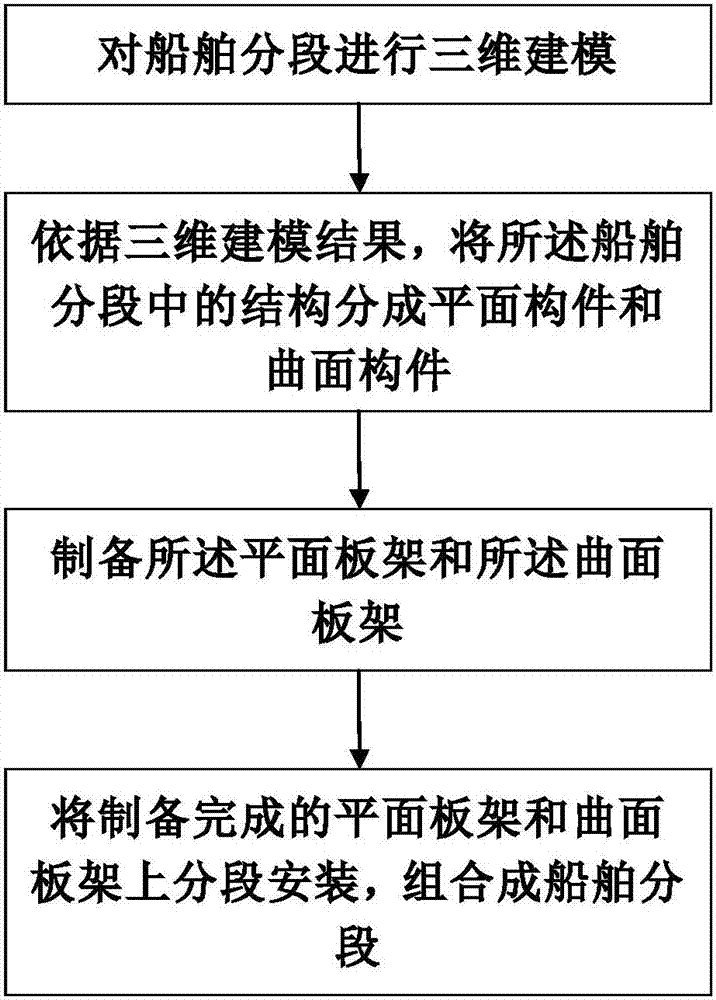

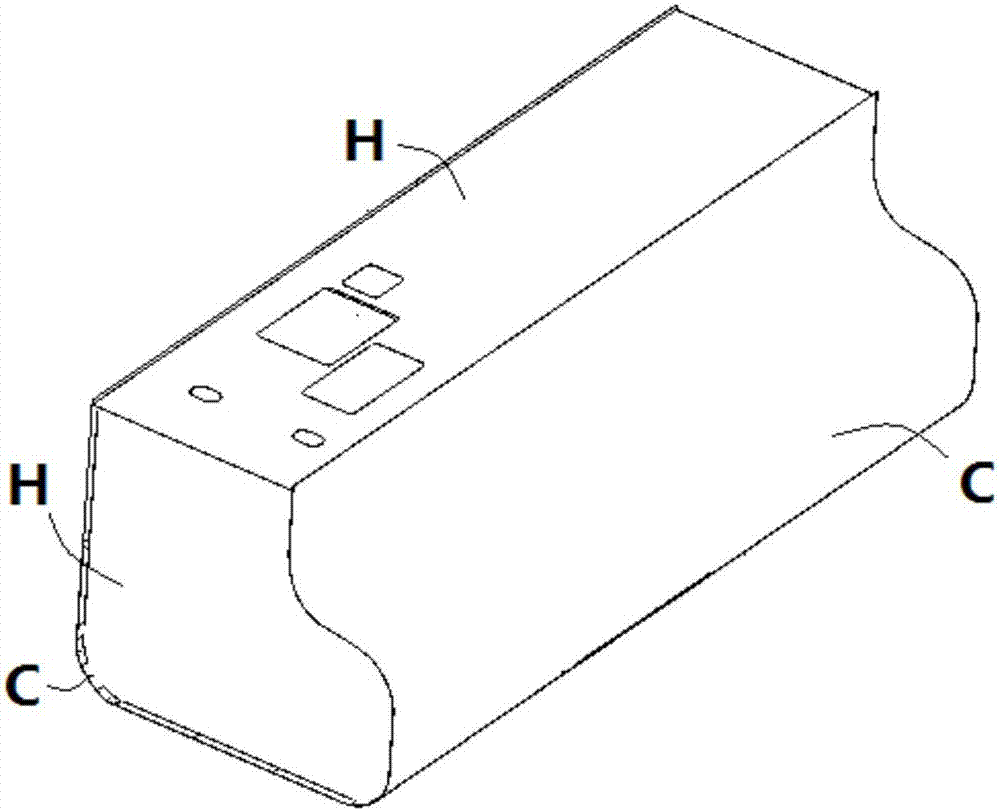

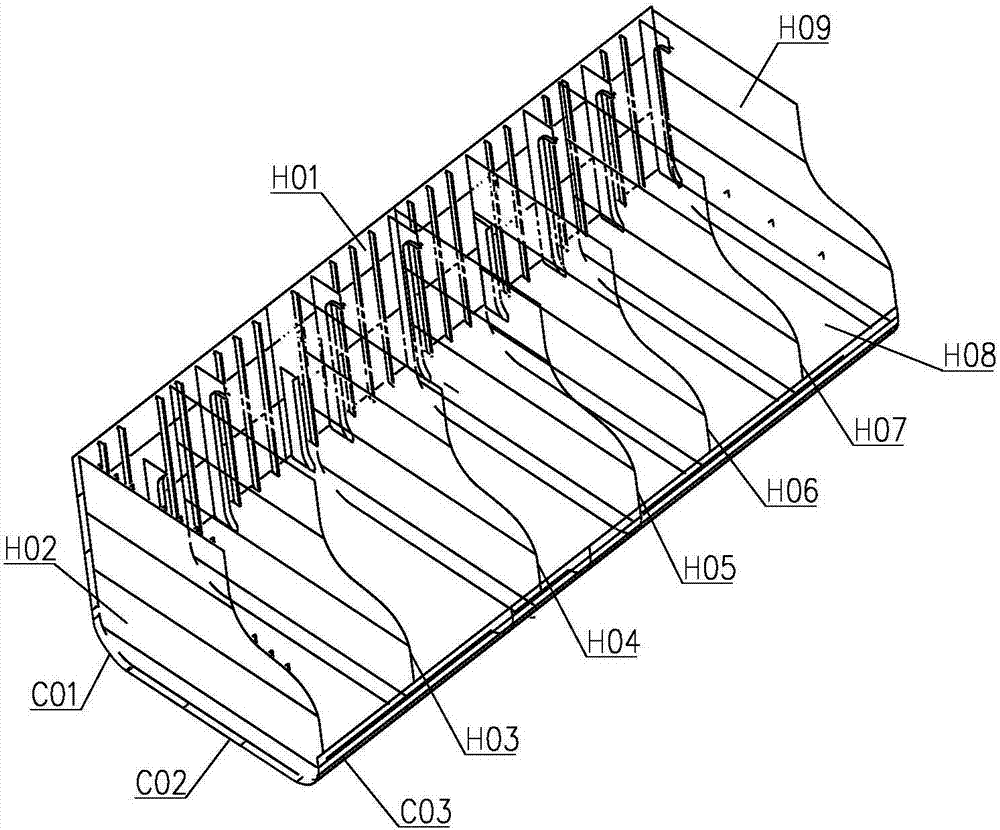

[0025] The embodiments of the present application provide a segmented rapid manufacturing method for large-scale special ships to solve the problem of long construction period, difficult construction, high labor intensity, harsh environment, structural accuracy and linear control reliability of the existing large-scale special ship segmental manufacturing method. The technical problem of control; the technical effect of improving the efficiency of ship segment manufacturing, reducing labor intensity, improving the accuracy of hull manufacturing and the reliability of line shape control has been achieved.

[0026] In order to better understand the above technical solutions, the above technical solutions will be described in detail below in conjunction with the accompanying drawings and specific implementation methods. It should be understood that the embodiments of the present invention and the specific features in the embodiments are detailed descriptions of the technical soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com