Fiber reinforce plastic (FRP) sectional material beam column joint capable of being assembled rapidly

A beam-column joint and profile technology, applied in the direction of building and building structure, can solve the problems of reduced column bearing capacity, difficult pouring, complicated structure, etc., and achieve the effects of good energy dissipation capacity, convenient construction and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

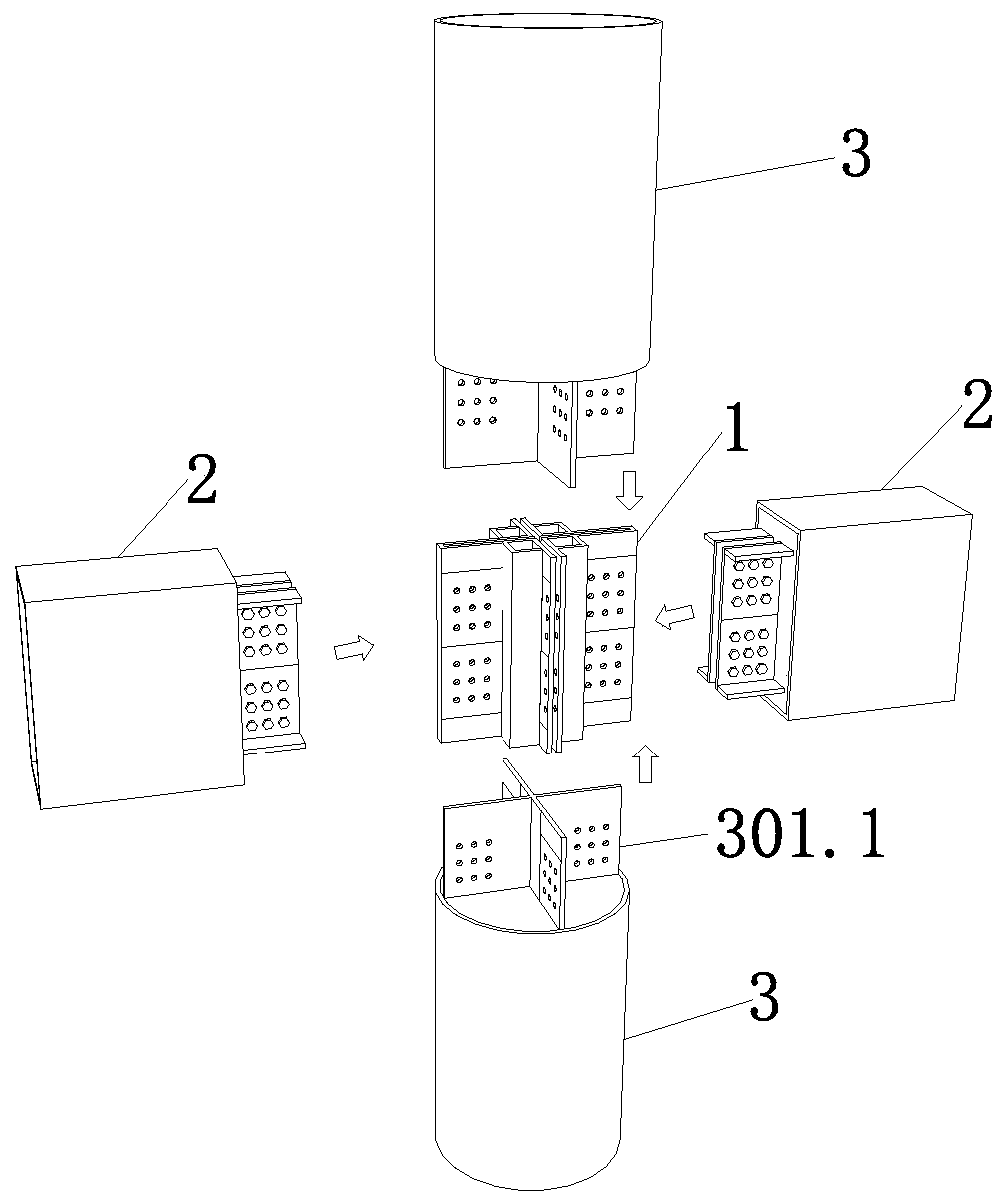

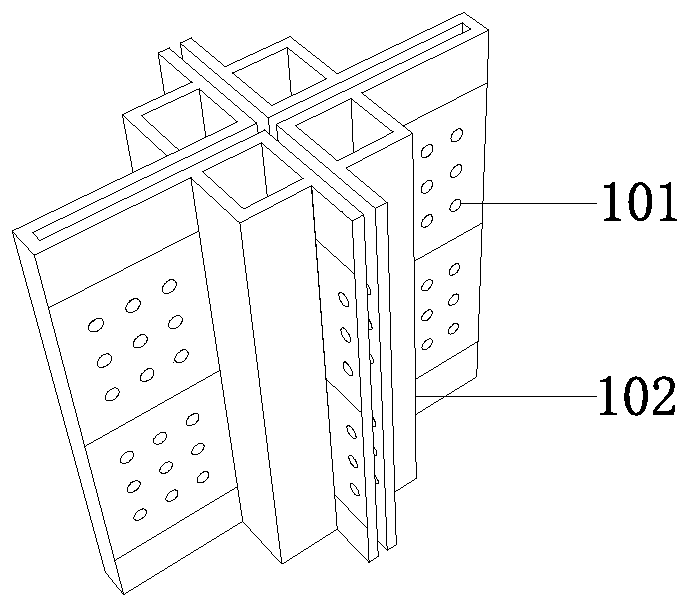

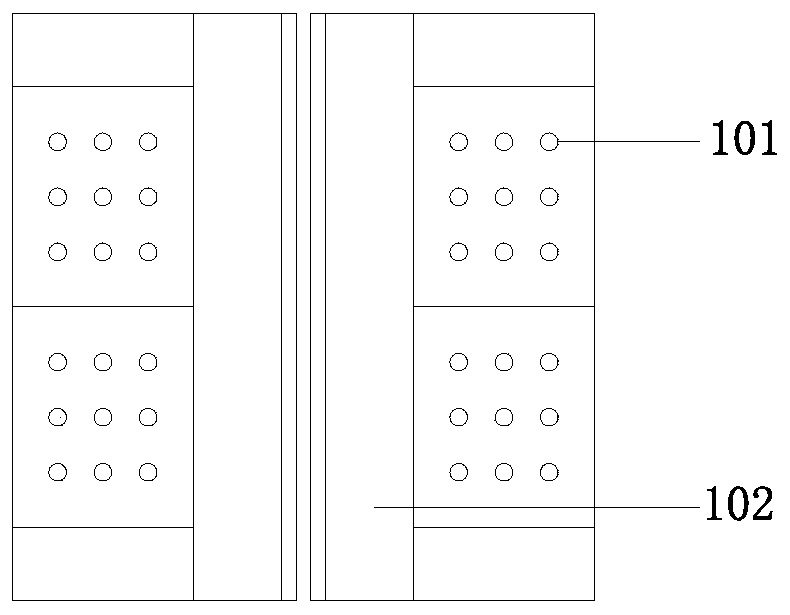

[0027] As shown in the figure, the FRP profile beam-column node that can be assembled quickly is characterized in that it includes a prefabricated node 1, two box-shaped FRP profile concrete composite beams 2, two FRP tubular concrete columns 3 embedded with cross FRP profiles and A number of bolts 4; the prefabricated node 1 is a split cross node, which is composed of two identical nodes to form a cross shape, and a plurality of first bolt holes 101 corresponding to the cross FRP profile of the FRP tubular concrete column 3 are preset in four directions; The first bolt holes 101 are arranged in no less than three columns in the two directions where the cross shape of the precast node 1 is connected to the FRP tubular concrete column 3, and the plurality of first bolt holes 101 are arranged in the other two directions of the cross shape of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com