Prestress assembly type high-performance concrete-filled square steel tubular column-concrete beam joint and construction method thereof

A technology of concrete-filled steel tube columns and reinforced concrete beams, which is applied to prestressed assembled high-performance square concrete-filled steel tube column-concrete beam joints and their construction fields, which can solve the problems of ineffective consumption of earthquake action, complex structures at joints, and reduction of column loads To achieve the effects of easy quality control, reduced stress concentration, and reduced residual deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

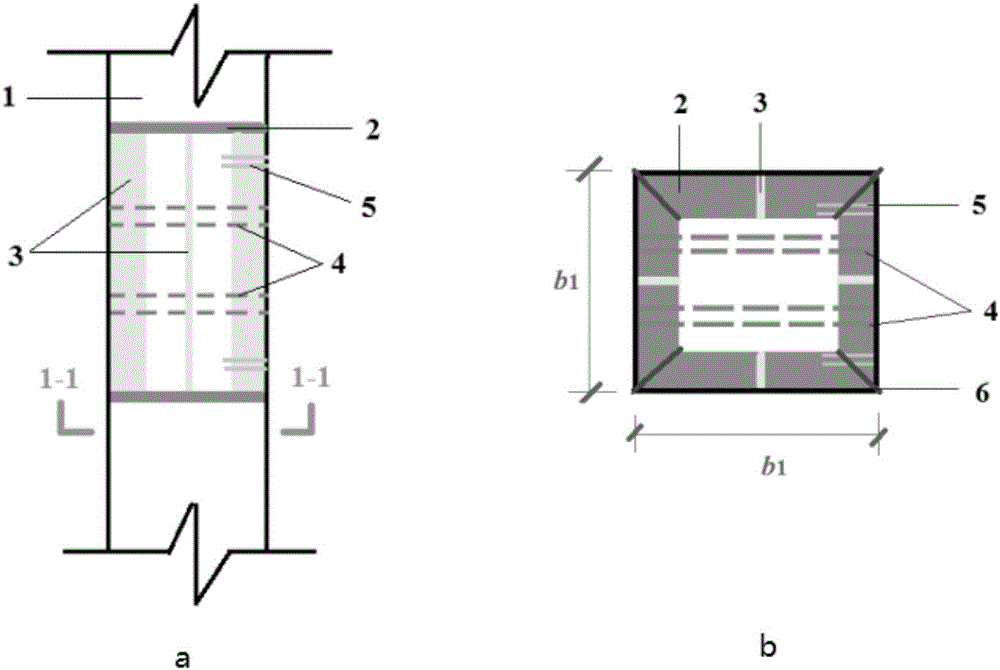

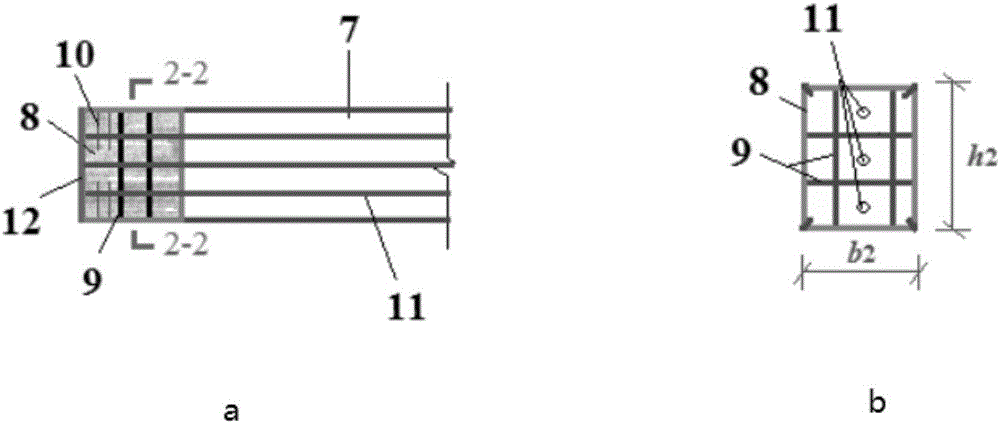

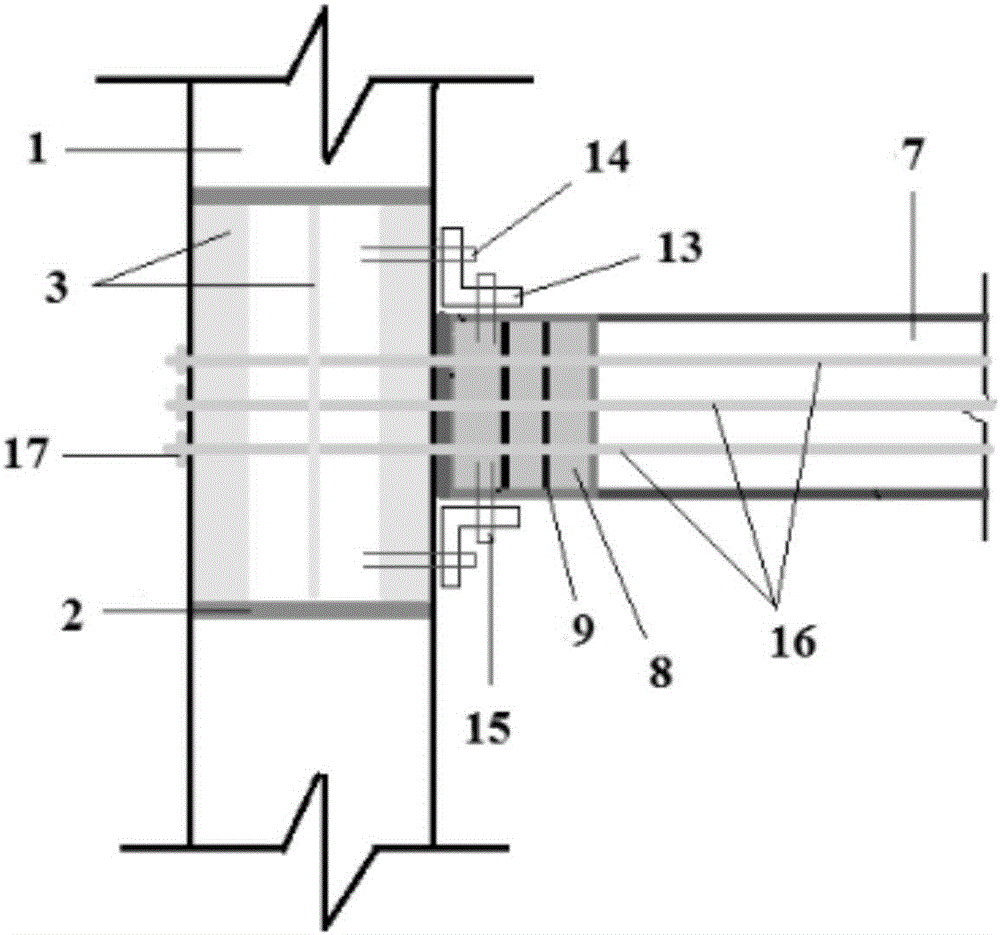

[0033] a Manufacture of steel pipe concrete column: the steel pipe is welded by 4 steel plates. Before welding, vertically weld two trapezoidal steel plates (2) with a thickness greater than 4mm on each steel plate, the trapezoidal steel plates (2) are parallel to the reinforced concrete beam (7), and the distance between the two trapezoidal steel plates (2) is greater than the height of the beam h +80mm, the width of the lower bottom of the trapezoidal steel plate (2) and the width of the steel tube concrete column (1) b 1 equal, the upper bottom width of the trapezoidal steel plate (2) is less than b 1 -30mm. Two trapezoidal steel plates (2) vertically weld a stiffener (3) with a thickness greater than 4mm in the middle, the stiffener (3) is located in the center of the steel plate, and the height of the stiffener (3) is equal to the vertical distance between the two trapezoidal steel plates (2) , the width of the stiffener (3) is the same as the height of the trapezoid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com