Integrated combined main shaft of mill combined machining center

A composite machining and spindle technology, used in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of low turning accuracy, high manufacturing cost, high maintenance cost, and inability to be used more widely, and achieve cost Low, high precision, enhanced rigidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

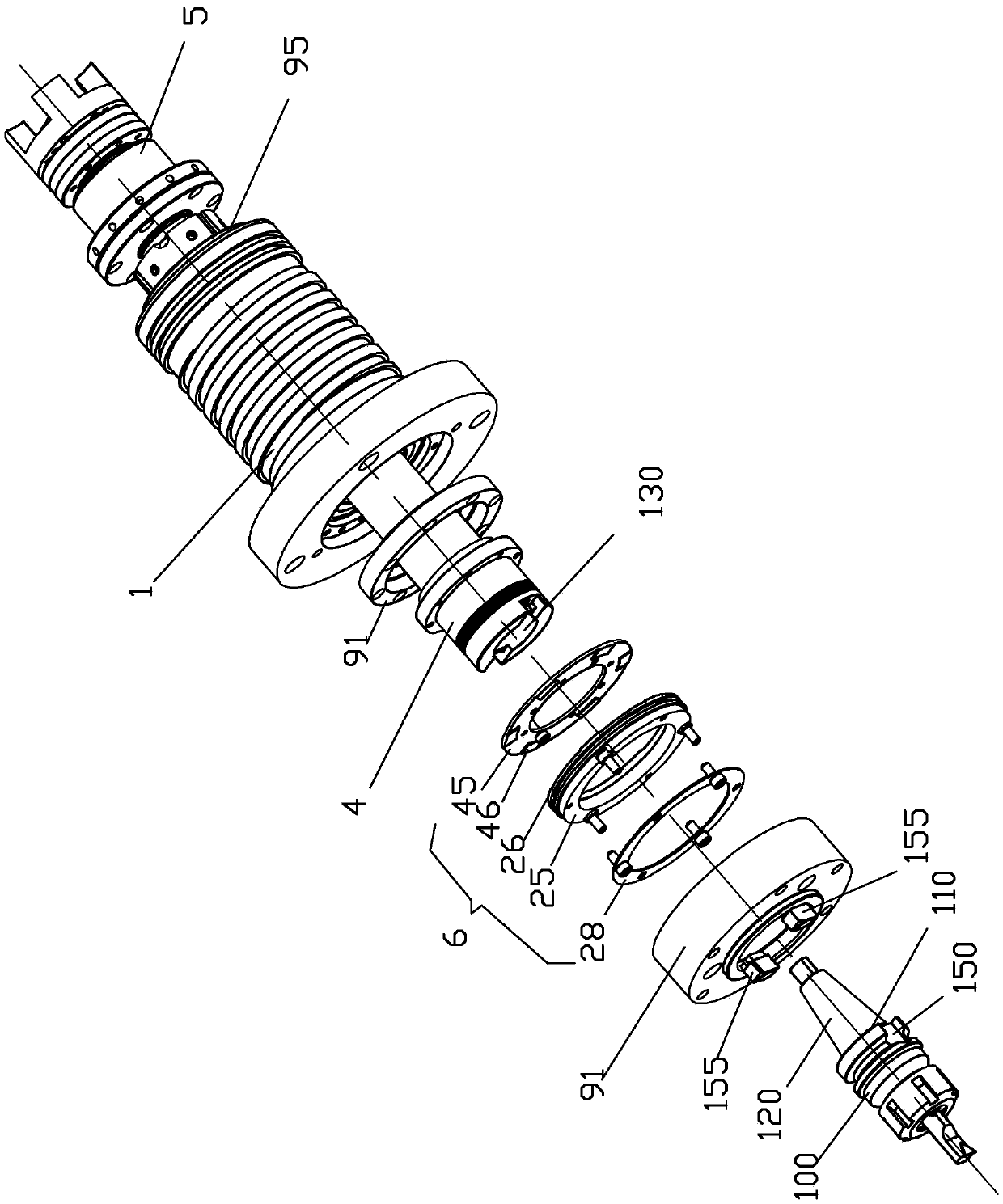

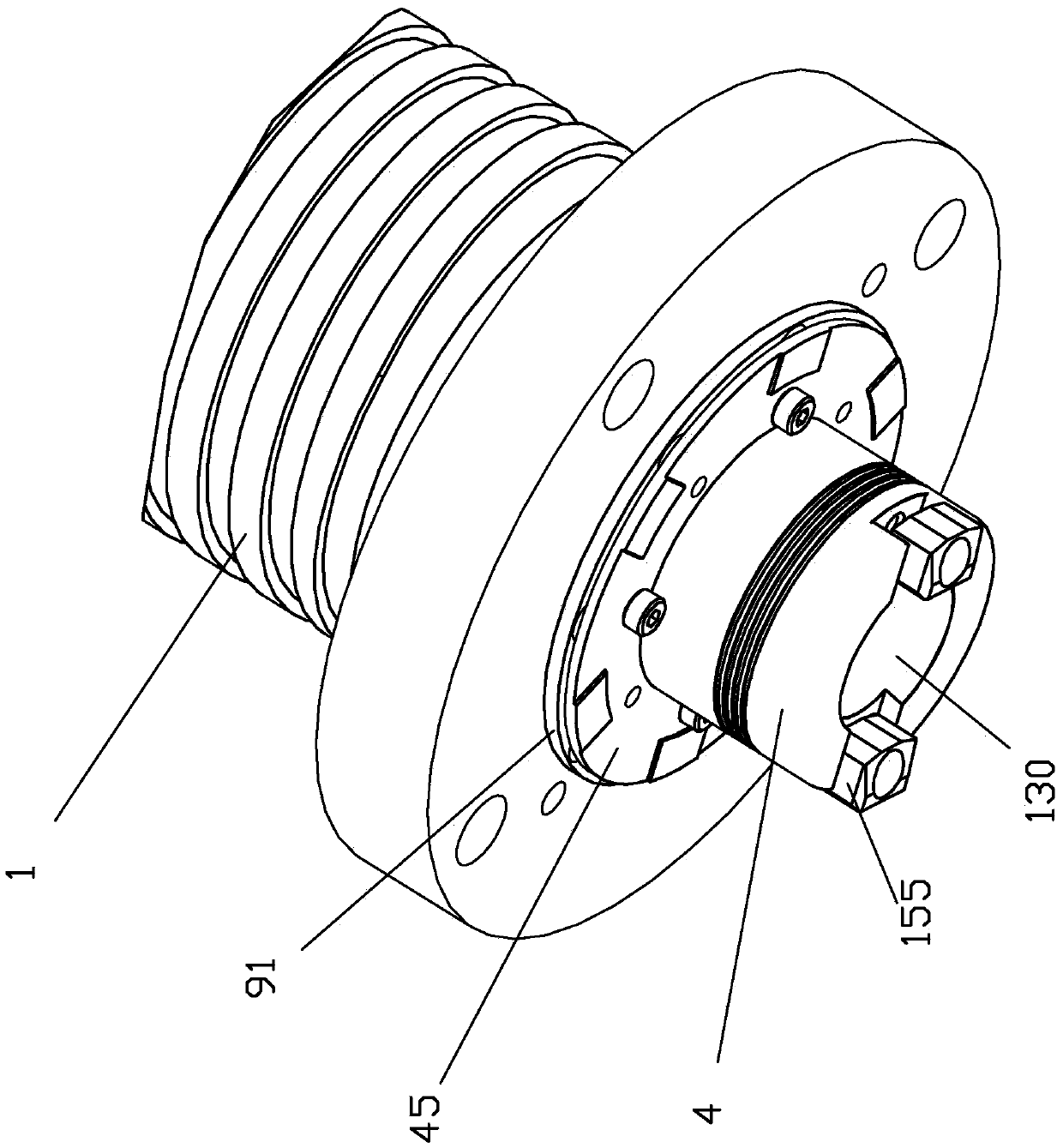

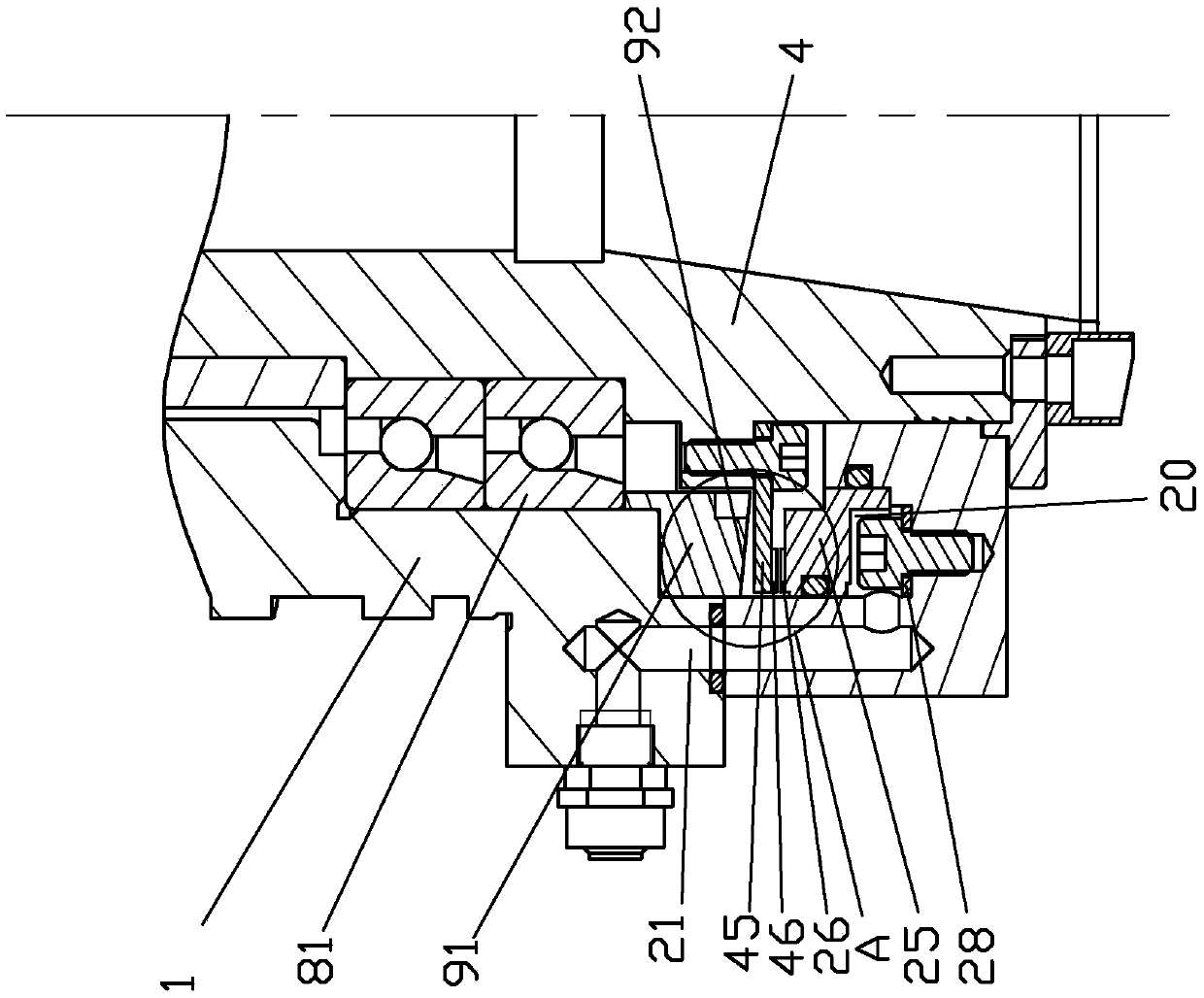

[0023] refer to Figure 1-Figure 11 , the integrated composite spindle of the milling-turning composite machining center of the present invention includes a spindle housing 1, a front end cover 2, a rear end cover 3, a spindle shaft core 4, a spindle drive mechanism 5, a locking device 6 and a broach loosening mechanism 7 .

[0024] Wherein, in view of the rear end cover 3, the main shaft drive mechanism 5 and the loose broach mechanism 7 are not the invention points of the present application, and can be replaced by common prior art, therefore, these several parts and mechanisms are not here one by one Be specific. Wherein, the main shaft driving mechanism 5 is driven to the main shaft through a coupling or a belt to provide the power source of the main shaft. In addition, the main motor has an accurate stop function, and the angular repeat positioning is 0.04 degrees.

[0025] The specific description and improvement are as follows: the main shaft housing 1 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com