Device and method for processing roller micro groove

A processing device and processing method technology, applied in metal processing equipment, tool clips, manufacturing tools and other directions, can solve the problems of increasing the cost of roller manufacturing, affecting the manufacture of optical brightness enhancement films, and being unfavorable for mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

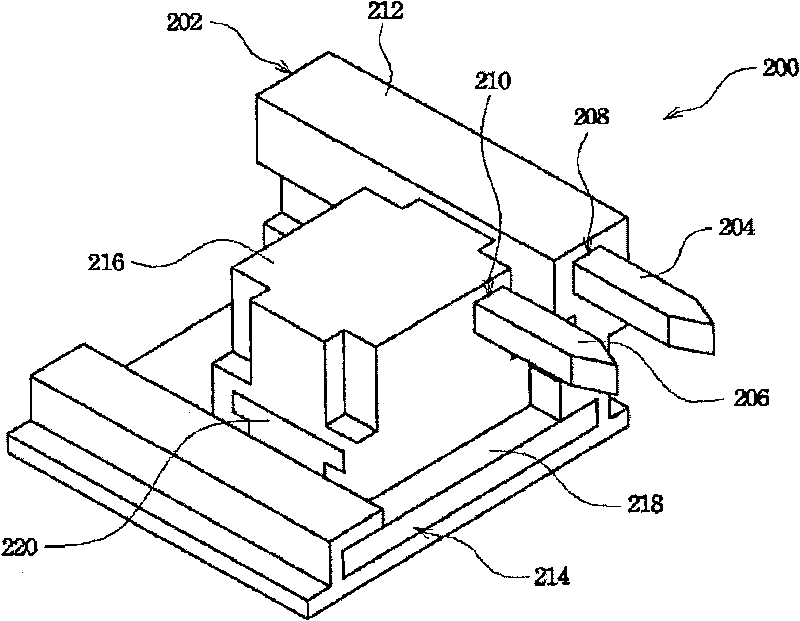

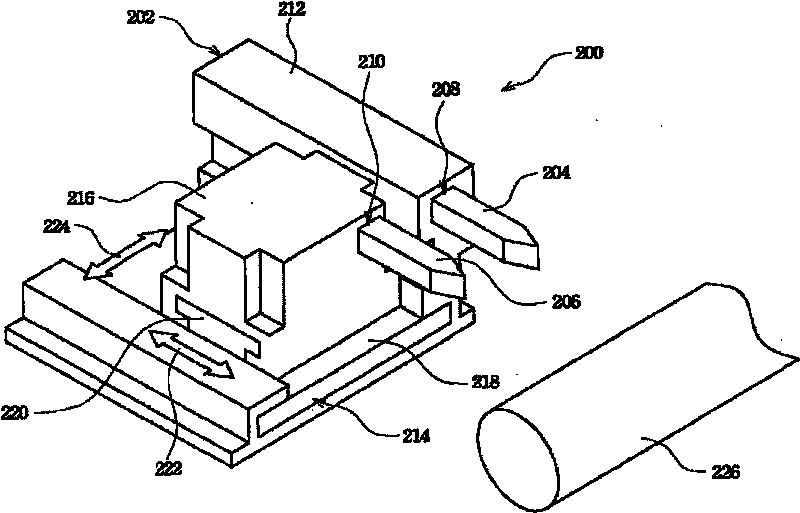

[0034] The invention discloses a processing device and a processing method for micro grooves of a roller. In order to make the narration of the present invention more detailed and complete, refer to the following description and cooperate Figure 2 to Figure 4 attached drawings.

[0035] Please refer to figure 2 , which is a three-dimensional schematic diagram illustrating a roller micro-groove processing device according to a preferred embodiment of the present invention. In an exemplary embodiment, the roller micro-groove processing device 200 can be used on a roller 226 (please refer to image 3 ) to define a micro-groove structure by cutting on the surface, wherein the roller 226 can be an optical film processing roller for making an optical film, such as an optical brightness enhancement film. The roller microgroove processing device 200 mainly includes a tool holder 202 and at least two tools, such as a rough turning tool 204 and a finishing turning tool 206 , wherei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com