Edge-sealing process for honeycomb plate without sealing edge

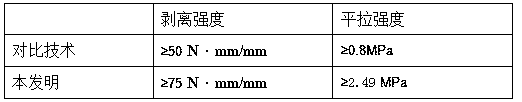

A honeycomb panel and process technology, which is applied in the field of edge-sealing process of honeycomb panels without edge-sealing, can solve the problems of difficulty in aligning the backboard frame, affecting product quality, and thick thickness at the folded edge, so as to achieve high edge-sealing efficiency, quality and Good uniformity and improved sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

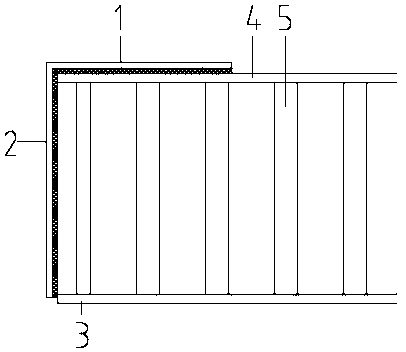

[0022] This embodiment discloses an edge-sealing process for honeycomb panels without edge-sealing. The edge-sealing process is mainly used for edge-sealing of straight plates without bending, specifically for straight plates such as rectangular plates, trapezoidal plates, triangular plates, and polygonal plates. Edge banding, the specific process is:

[0023] (1) Customize the L-shaped profile including the first side panel 1 and the second side panel 2 according to the size of the honeycomb panel without edge banding. Specifically, use a single-head saw or a double-head saw to cut the customized L-shaped profile, and the L-shaped profile The length is adapted to the length of each side of the honeycomb panel without edge sealing, and the thickness of the L-shaped profile is 0.8-1.5mm, preferably 1.2mm.

[0024] (2) Structural glue is applied around and on each side of the back panel 4 of the honeycomb panel without edge banding. Specifically, a glue machine is used to evenly...

Embodiment 2

[0034] On the basis of Example 1, this embodiment discloses an edge-sealing process for honeycomb panels without edge-sealing. The edge-sealing process is mainly used for edge-sealing special-shaped bent plates. The straight plate has a certain angle (right angle, acute angle, acute angle) after bending, and the surface is not a flat plate. When sealing the edge, it is necessary to open a slot on the back plate 4 and bend it to a required angle, and the depth and width of the slot body are determined according to the required bending angle. After slotting, apply structural glue in the tank body and both sides of the tank body, and use reinforcements to connect the back plates 4 on both sides of the tank body. After the special-shaped bending plate is fixed, a special-shaped honeycomb panel without edge sealing is obtained, and then according to the embodiment Step 1 in custom L-shaped profile for edge banding.

[0035] In this embodiment, the reinforcing member is preferably ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com