A fast packaging machine

A technology of packaging machinery and equipment, applied in the field of rapid packaging machinery and equipment, can solve the problems of poor heat sealing stability, insufficient accuracy, general edge sealing effect, etc., and achieve the effect of safe and efficient use, improved accuracy, and increased heat sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

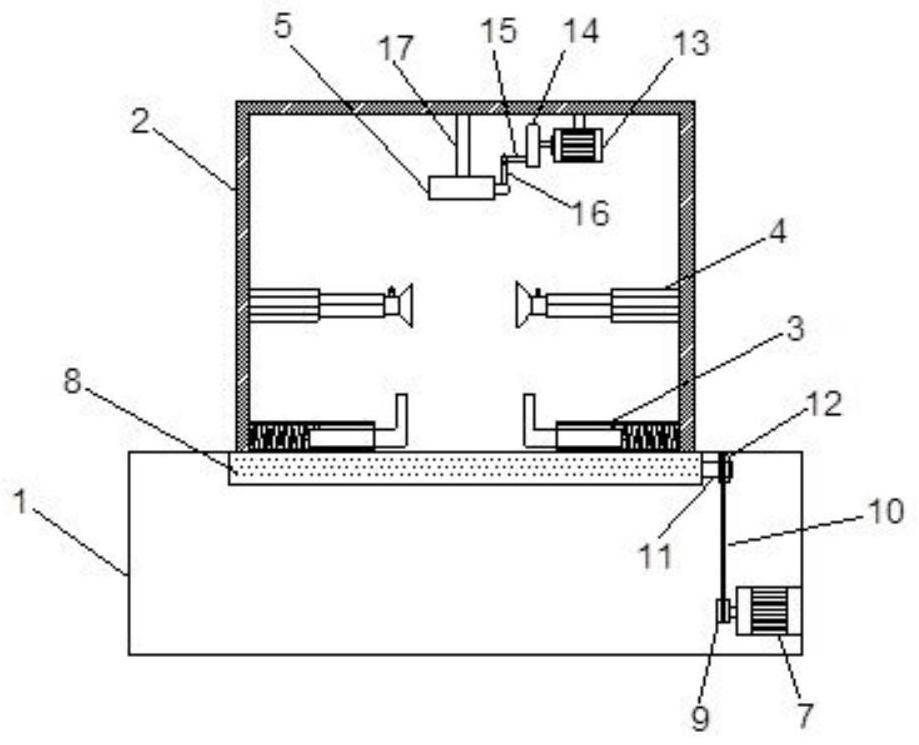

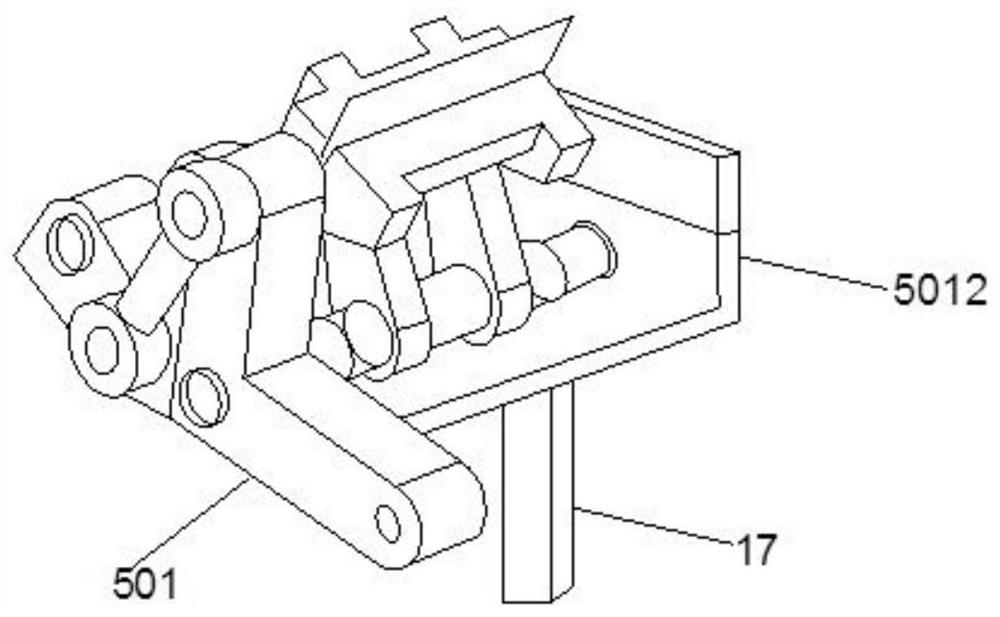

[0034] Such as Figure 1-5 As shown, a kind of rapid packaging mechanical equipment; including a base 1 and a casing 2; the casing 2 is arranged above the base 1, the inside of the base 1 is a hollow structure, and the bottom of the base 1 near one end is provided with a first motor 7. The output shaft of the first motor 7 is connected with a driving sprocket 9, the driving sprocket 9 is matched with a chain 10, the other end of the chain 10 is connected with a driven sprocket 12, and the driven sprocket is connected with Roller shaft 11, described roller shaft 11 driving is connected with conveyor belt 8, and described conveyor belt 8 is arranged on the top of base 1; Housing 2 cover is arranged on the top of conveyor belt 8; Two sets of fixing mechanisms 3, two groups of pressure opening mechanisms 4 are arranged symmetrically above the fixing mechanism 3; a second motor 13 is arranged on the top of the housing 2, and a cam 14 is connected to the output shaft of the second m...

Embodiment 2

[0038] A fast packaging mechanical equipment; including a base 1 and a casing 2; the casing 2 is arranged above the base 1, the inside of the base 1 is a hollow structure, and the bottom of the base 1 near one end is provided with a first motor 7, and the second The output shaft of a motor 7 is connected with a driving sprocket 9, the driving sprocket 9 is matched with a chain 10, the other end of the chain 10 is connected with a driven sprocket 12, and the driven sprocket is connected with a roller 11 , the roller 11 is drivingly connected with a conveyor belt 8, and the conveyor belt 8 is arranged on the top of the base 1; the housing 2 is covered on the top of the conveyor belt 8; Mechanism 3, two sets of pressure opening mechanisms 4 are arranged symmetrically above the fixing mechanism 3; a second motor 13 is arranged on the top of the housing 2, and a cam 14 is connected to the output shaft of the second motor 13, and the cam 14 The other side is rotatably connected with...

Embodiment 3

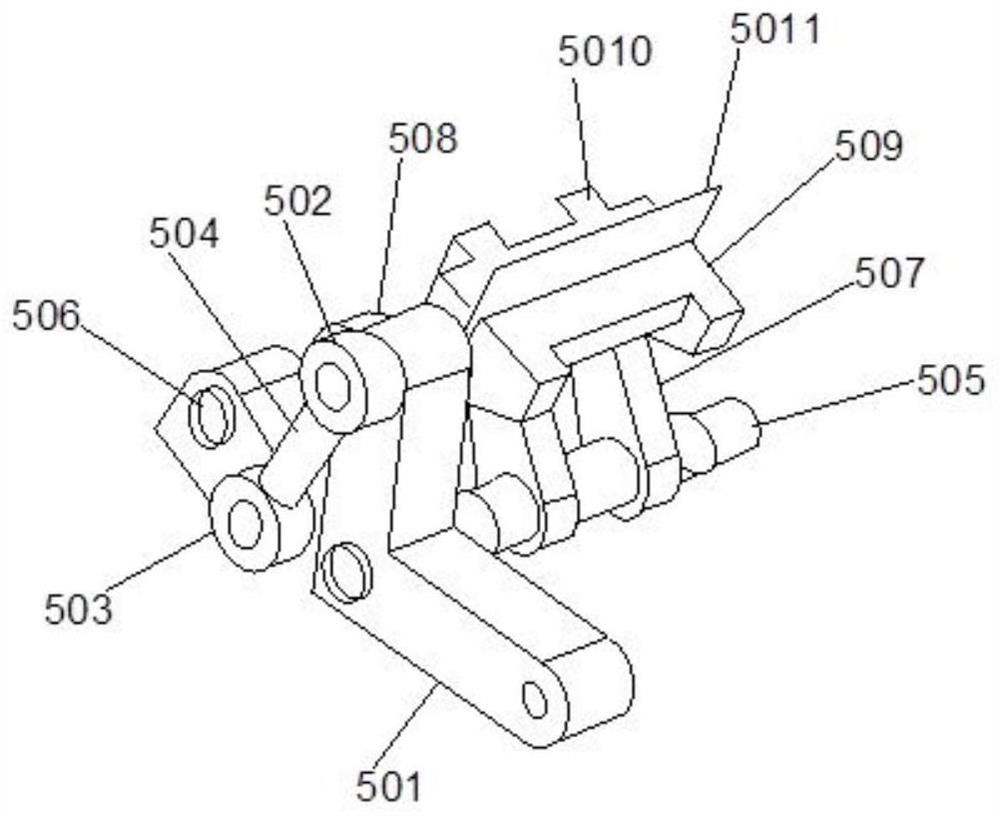

[0043] On the basis of Embodiment 1, the active heat-sealing cutter head 509 of the heat-sealing mechanism is the positive electrode of the parallel plate, and the driven heat-sealing cutter head 5010 is the negative electrode of the parallel plate. Between the sealing cutter head 509 and the driven heat-sealing cutter head 5010, high-frequency current is passed to the active heat-sealing cutter head 509 and the driven heat-sealing cutter head 5010, and the strong electric field makes each double dipole forming the film obey the field strength Direction arrangement, high-frequency field strength direction changes, driving the double dipoles to repeatedly oscillate and collide, friction generates a lot of heat, and makes the food bags melt together; the frequency λ of the current determines the height of the heat-sealing temperature T, λ The value range of 6k-15kHz; heat sealing temperature T = δ·λ / 3; δ is the temperature coefficient, the value range is 0.0323-0.098; T unit is ℃...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com