Internal edge sealing device

A technology of edge banding equipment and edge banding machine, which is applied to wood processing appliances, household components, etc., can solve the problems of large size, skew, time-consuming and labor-intensive edge banding equipment, and achieves improved edge banding efficiency, reduced equipment costs, The effect of simplifying the size and structure of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in conjunction with the accompanying drawings.

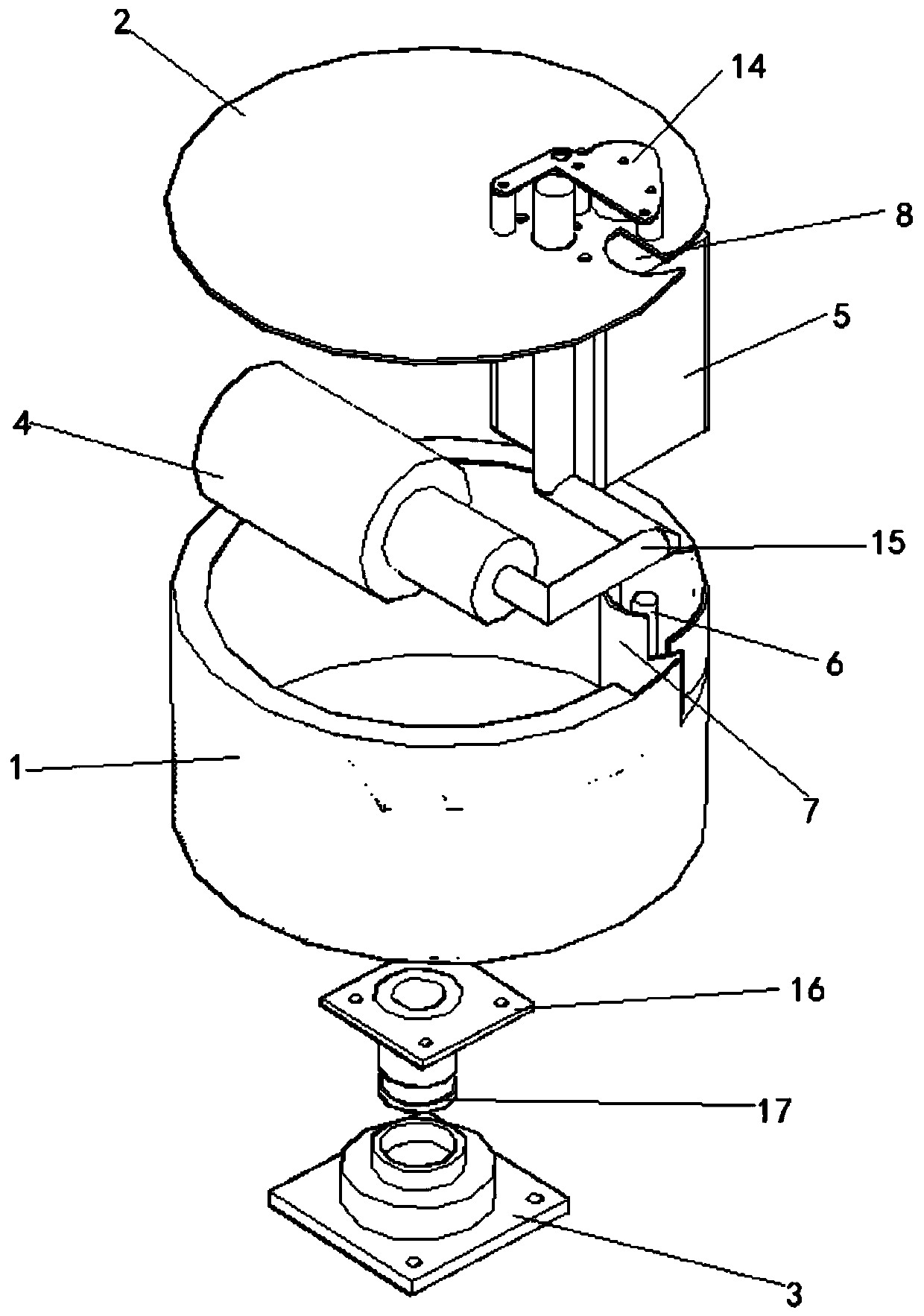

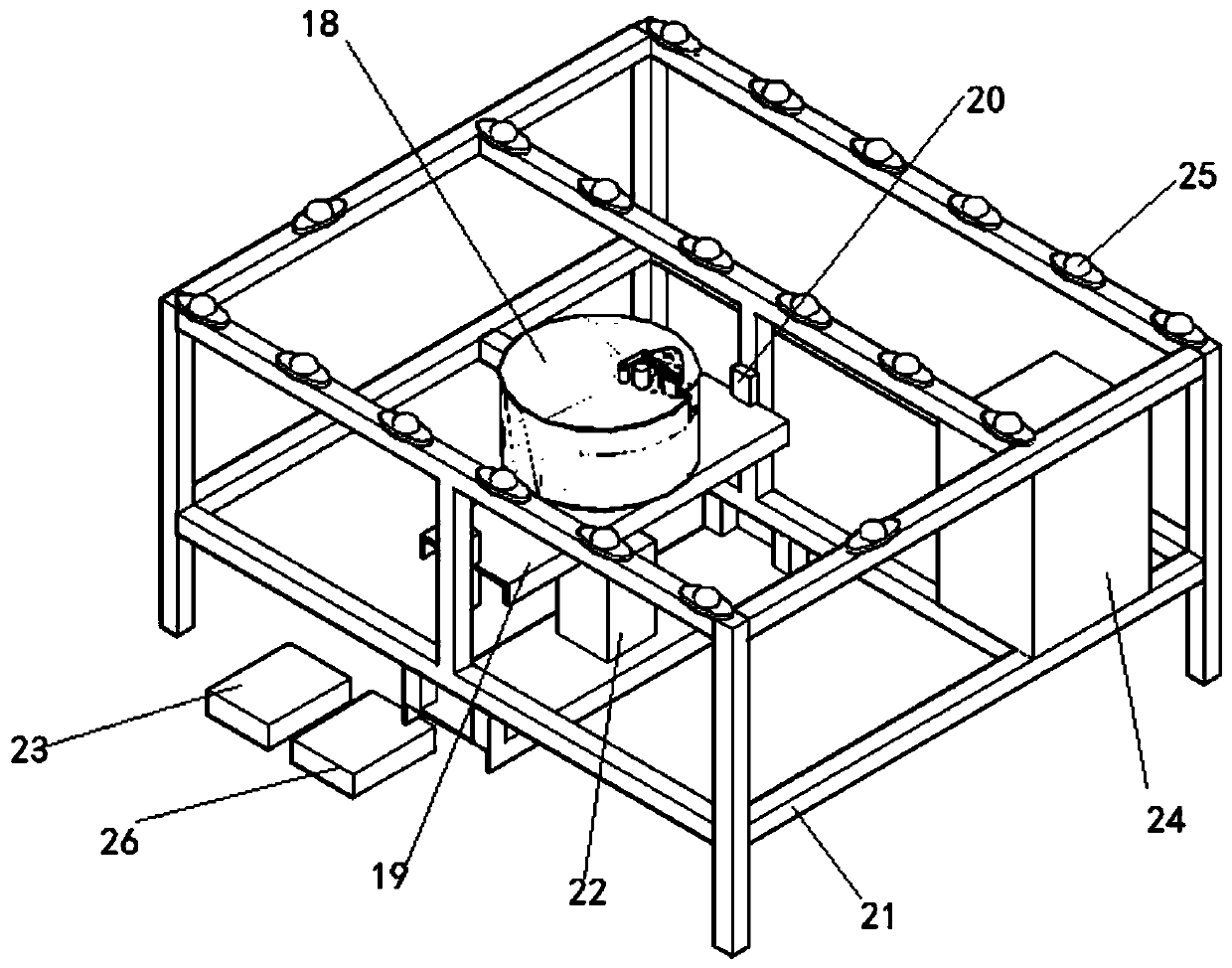

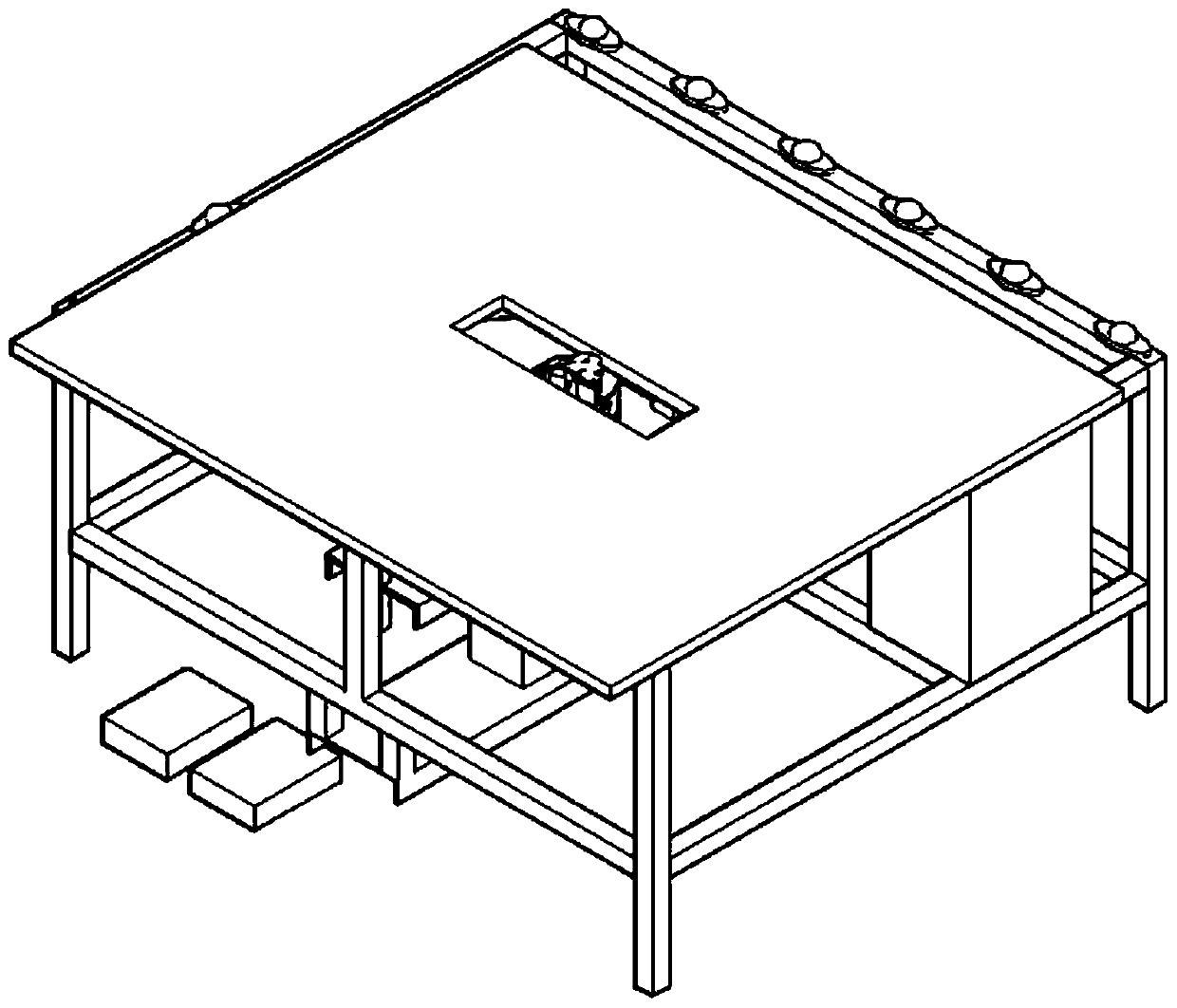

[0015] see Figure 1~4 , the present invention designs an inner edge banding device, including: an edge banding machine, characterized in that: the edge banding machine 18 includes an outer shell 1, an upper cover 2, and a bearing seat 3, and the outer shell 1 is installed with Adjustable blower 4, motor 5 and roller 3 6, the position of roller 3 6 is close to the inner wall of the outer casing 1, and a semi-arc guide plate 7 is provided beside the roller 3 6, and the edge of the upper cover 2 is provided with a semicircular Recessed groove 8, one side of semicircular recessed groove 8 is fixed with roller one 9, one side of roller one 9 close to the center of the upper cover 2 is fixed with roller two 10, next to roller two 10 is fixed with transmission shaft 11, The power shaft 12 is fixed beside the transmission shaft 11, and the side position of the power shaft 12 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com