Edge banding process for furniture panels and its special edge banding device

A board and process technology, applied in the field of furniture board edge banding technology and its special edge banding device, can solve the problems of complex equipment, inconvenient operation, cumbersome processing process, etc., achieve simple processing technology, convenient operation, and improve edge banding efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

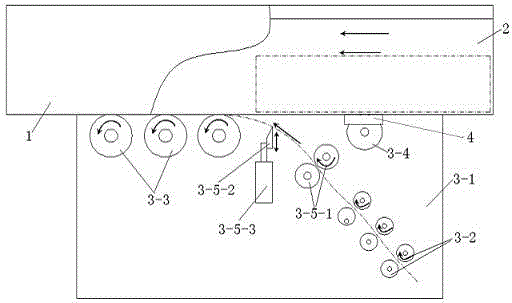

[0017] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

[0018] The present invention relates to a kind of edge banding process of furniture board, which is carried out according to the following process:

[0019] a) The plate is adsorbed to the liftable conveying platform through the suction plate, and transferred to the next conveyor by the conveyor belt on the platform;

[0020] b) The plates running along the conveyor are pre-pressed on the discharge side of the conveyor to ensure the flatness of the plates during the downward conveying process;

[0021] c) Convey from the previous conveyor to the next conveying platform, and press the material by the pressing guide wheel on the feeding side of the conveying platform;

[0022] d) Convey from the next conveying platform into the special edge banding device for ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com