Novel continuous edge sealing system for kitchen cabinet plates and continuous edge sealing method for novel continuous edge sealing system

A panel and kitchen cabinet technology, which is applied in the field of continuous edge banding system for new kitchen cabinet panels, can solve the problems of high production cost, time-consuming and labor-consuming, and low processing efficiency, so as to reduce the probability of damage and reduce the rate of collision damage , Improve the effect of edge banding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing:

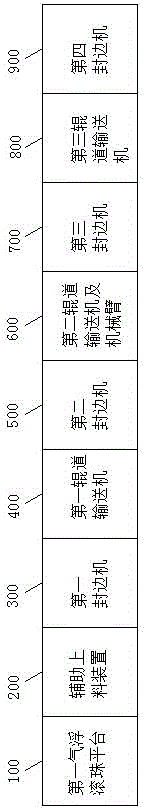

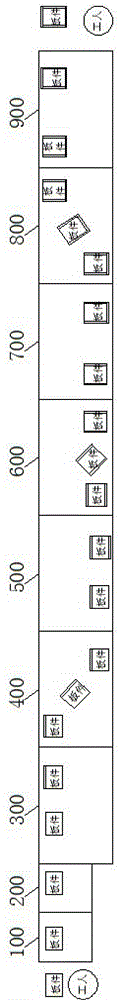

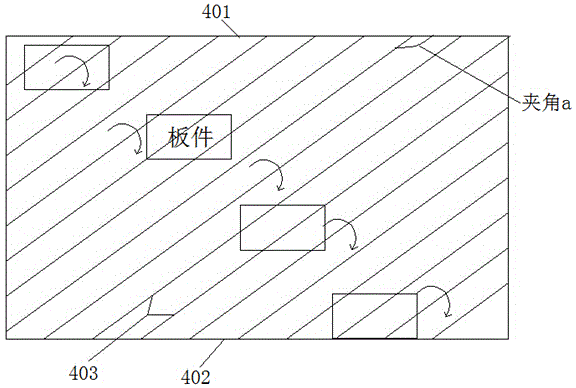

[0041] Such as Figure 1-Figure 12 A new type of continuous edge banding system for kitchen cabinet panels shown includes a first air-floating ball platform 100, an auxiliary feeding device 200, a first edge banding machine 300, a first roller conveyor 400, a second Edge banding machine 500 , second roller conveyor 600 , third edge banding machine 700 , third roller conveyor 800 and fourth edge banding machine 900 . A mechanical arm for adjusting the placement direction of the panels is arranged above the second roller conveyor, figure 1 600 in represents the second roller conveyor and mechanical arm. The first edge banding machine 300 and the third edge banding machine 700 are located on the same side, and the second edge banding machine 500 and the fourth edge banding machine 900 are located opposite to the first edge banding machine 300 the other side.

[0042] exist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com