A conveying device that uses conveying airflow to control the process of material throwing

A technology for conveying air flow and conveying device, which is applied in the field of agricultural machinery, can solve problems such as collision, and achieve the effects of reducing the collision damage rate, improving the utilization rate of air flow, and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038]The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

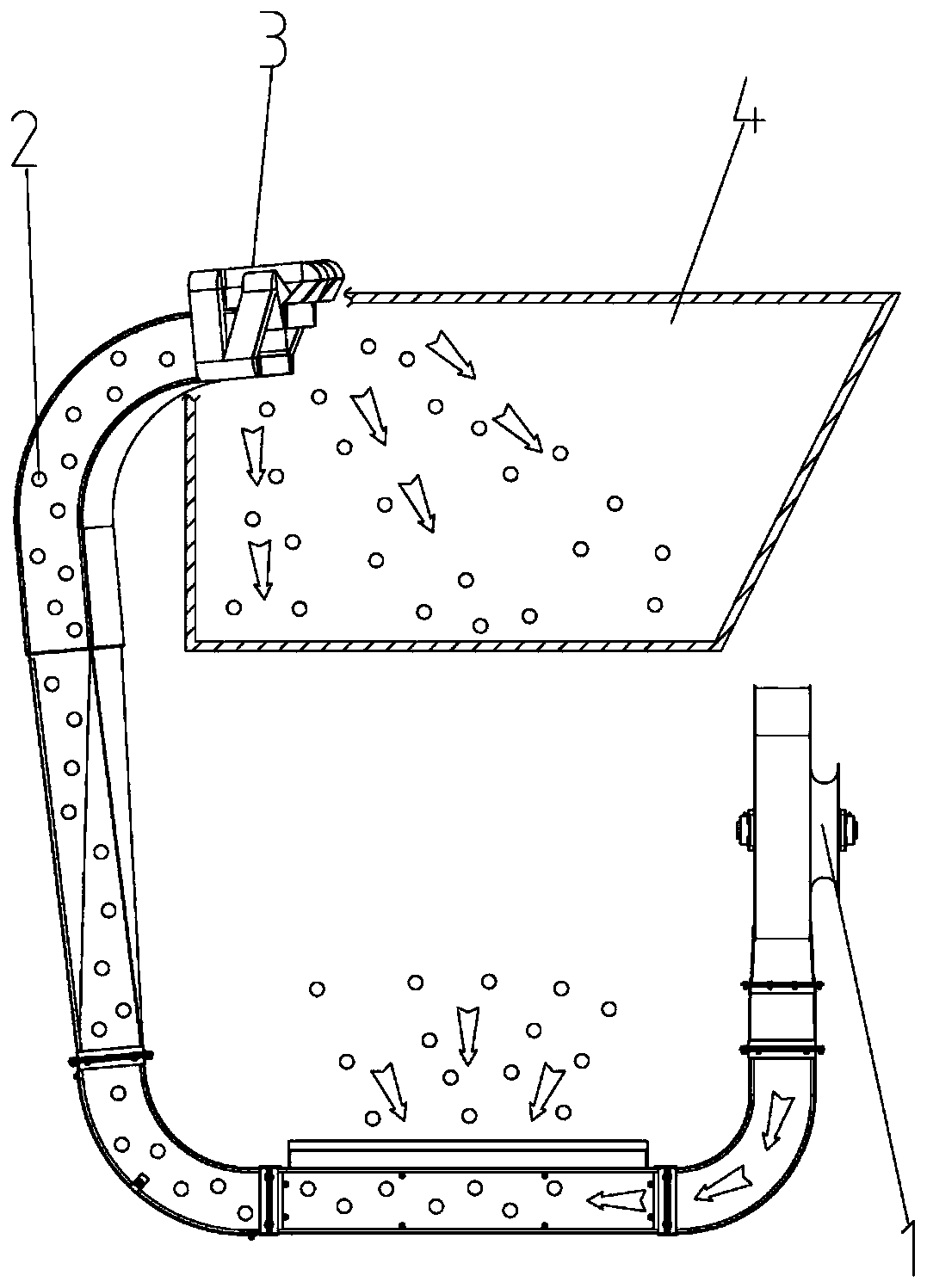

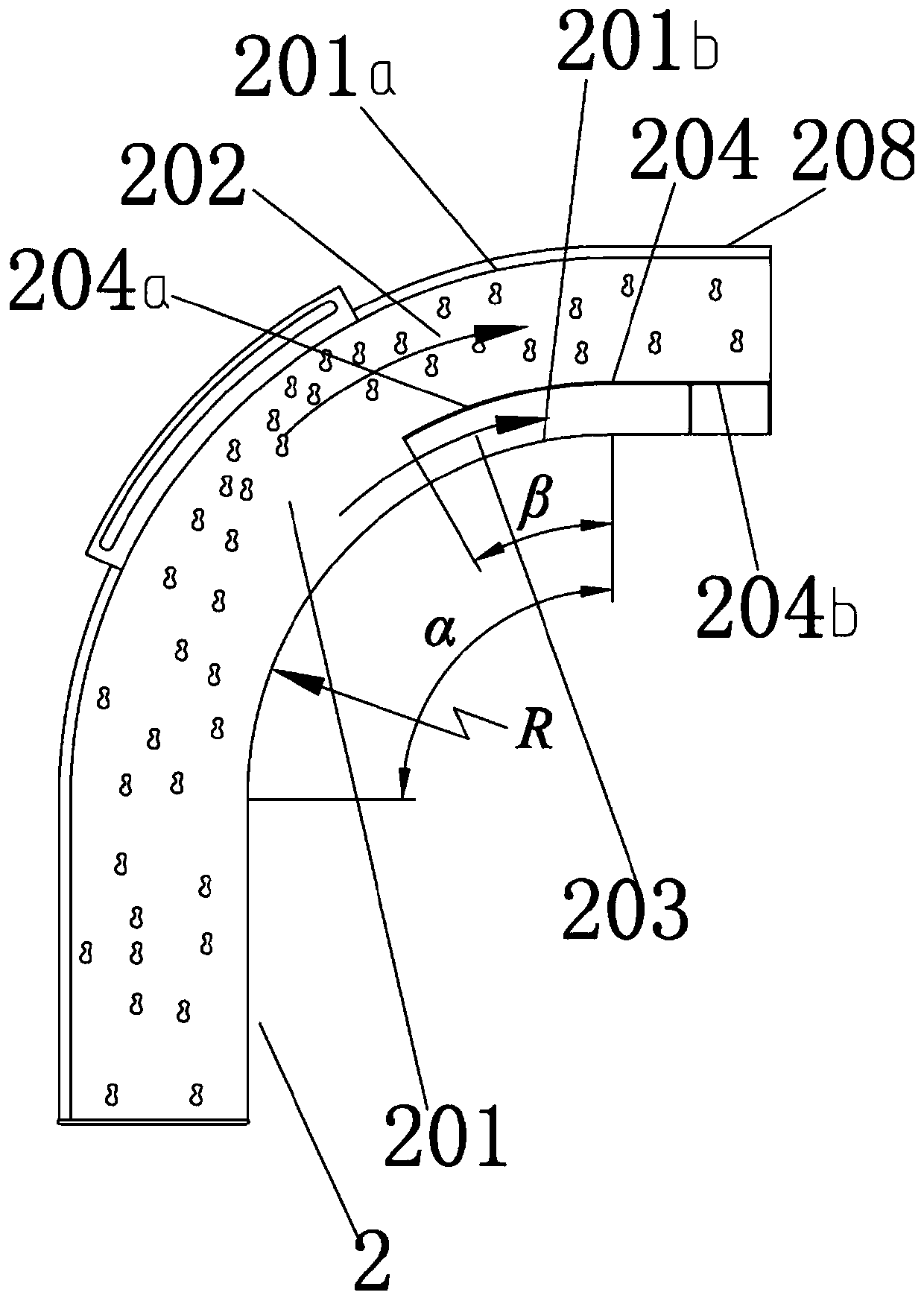

[0039] like Figure 1-10 As shown, a conveying device that utilizes conveying air flow to control the material throwing process includes a conveying pipeline 2, the feed pipe section of the conveying pipeline 2 is connected to an air source equipped with a large centrifugal fan 1, and the discharge pipe section 208 of the conveying pipeline 2 is set on the top And it is at the position of the upper feeding side of the silo 4.

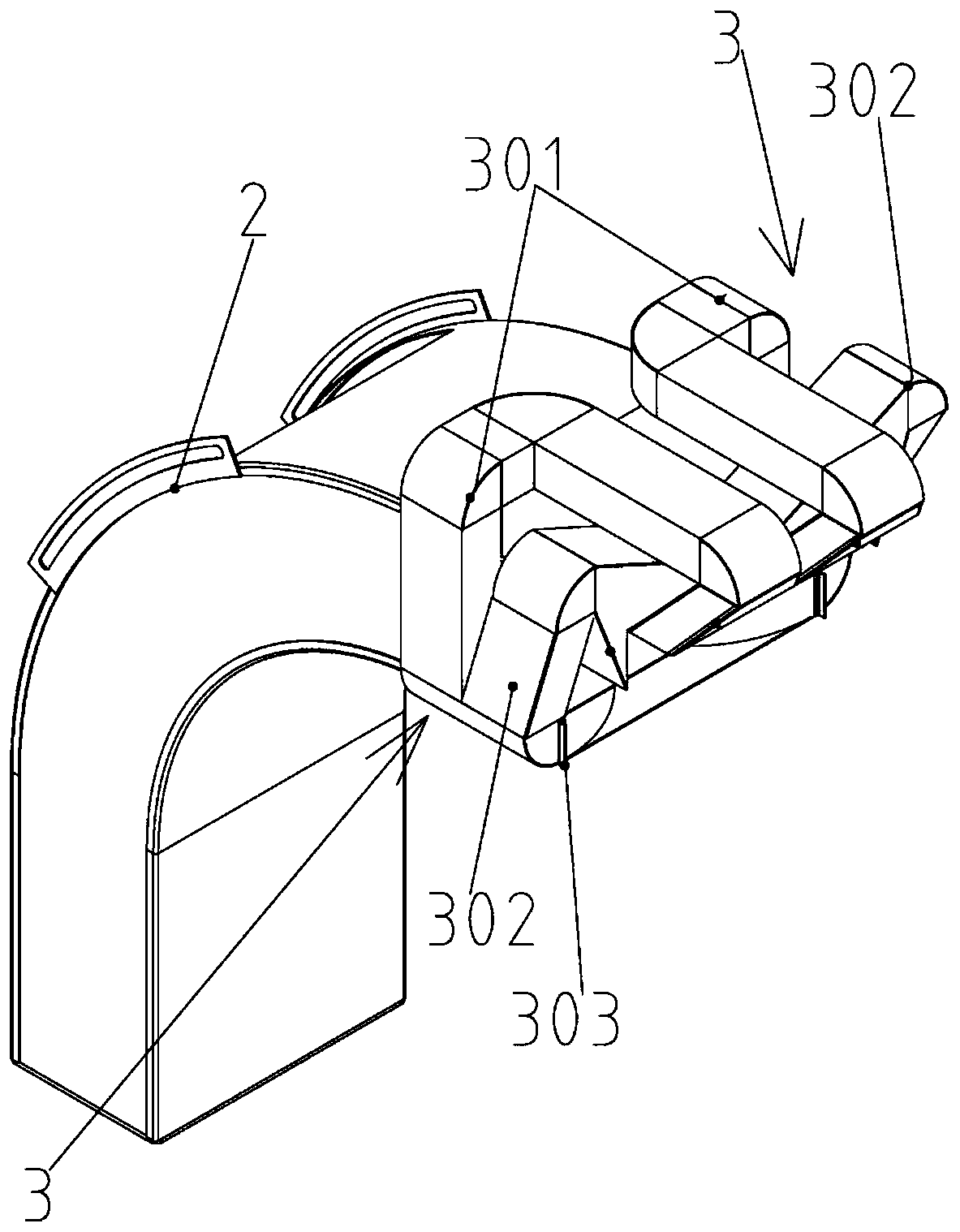

[0040] The discharge pipe section 208 of the above-mentioned conveying pipeline 2 is equipped with a pair of guide pipe groups 3 in the direction of falling material. Based on the angle of view perpendicular to the outlet end face of the discharge pipe section 208, the two guide pipe groups 3 in the direction of discharge are respectively arranged at the ends of the conveying pipe 2. On the left and right sides of the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com