Edge sealing device for SBS modified asphalt waterproof roll

A technology for a waterproofing membrane and an edge-sealing device, which is applied in the field of waterproofing membrane construction, can solve the problems of low edge-sealing efficiency, poor waterproofing construction effect, and imprecision of the waterproofing membrane, so as to improve the quality and efficiency of edge-sealing and improve Edge effect, the effect of improving the effect of edge sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to facilitate those skilled in the art to understand the technical solution of the present invention, the technical solution of the present invention will be further described in conjunction with the accompanying drawings.

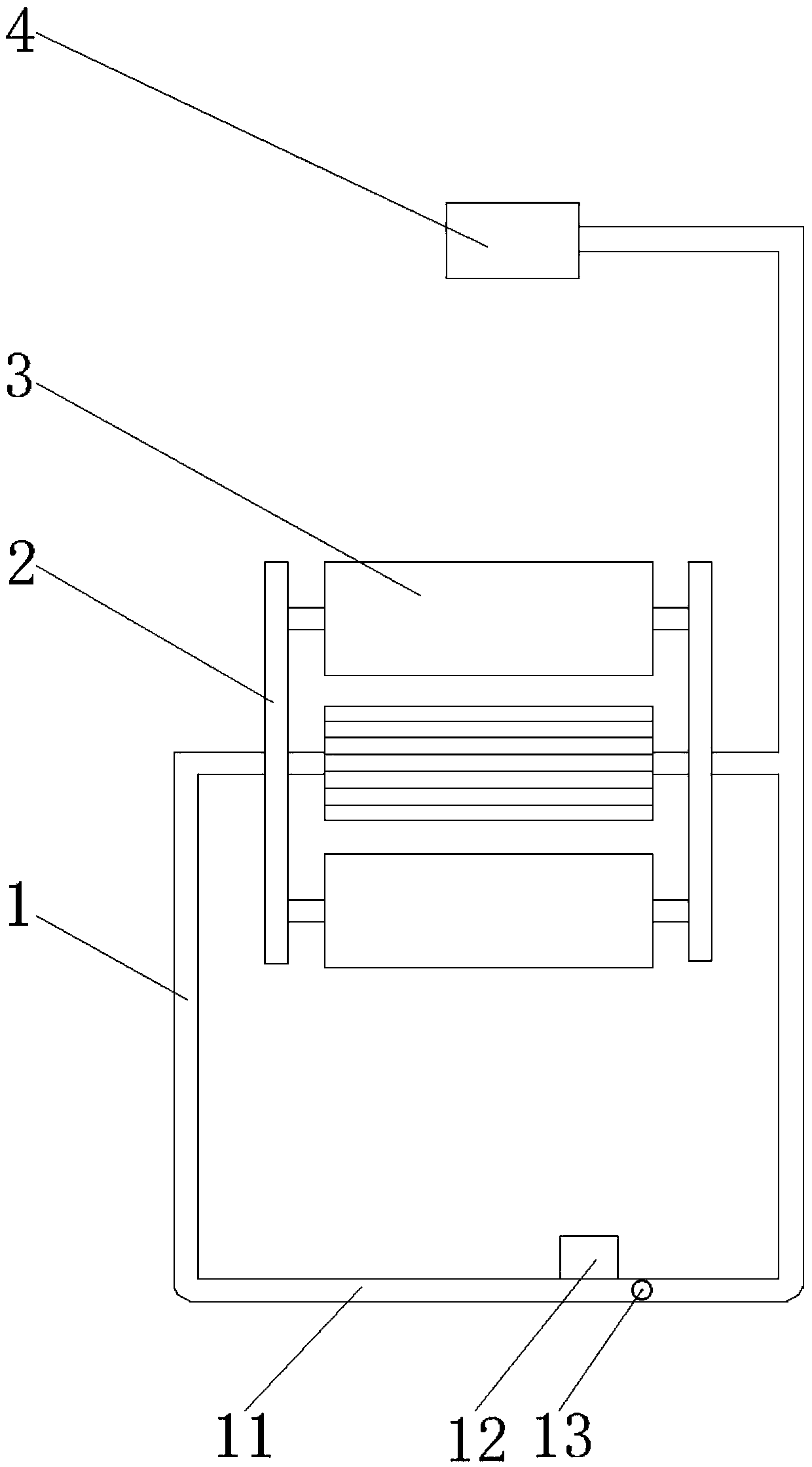

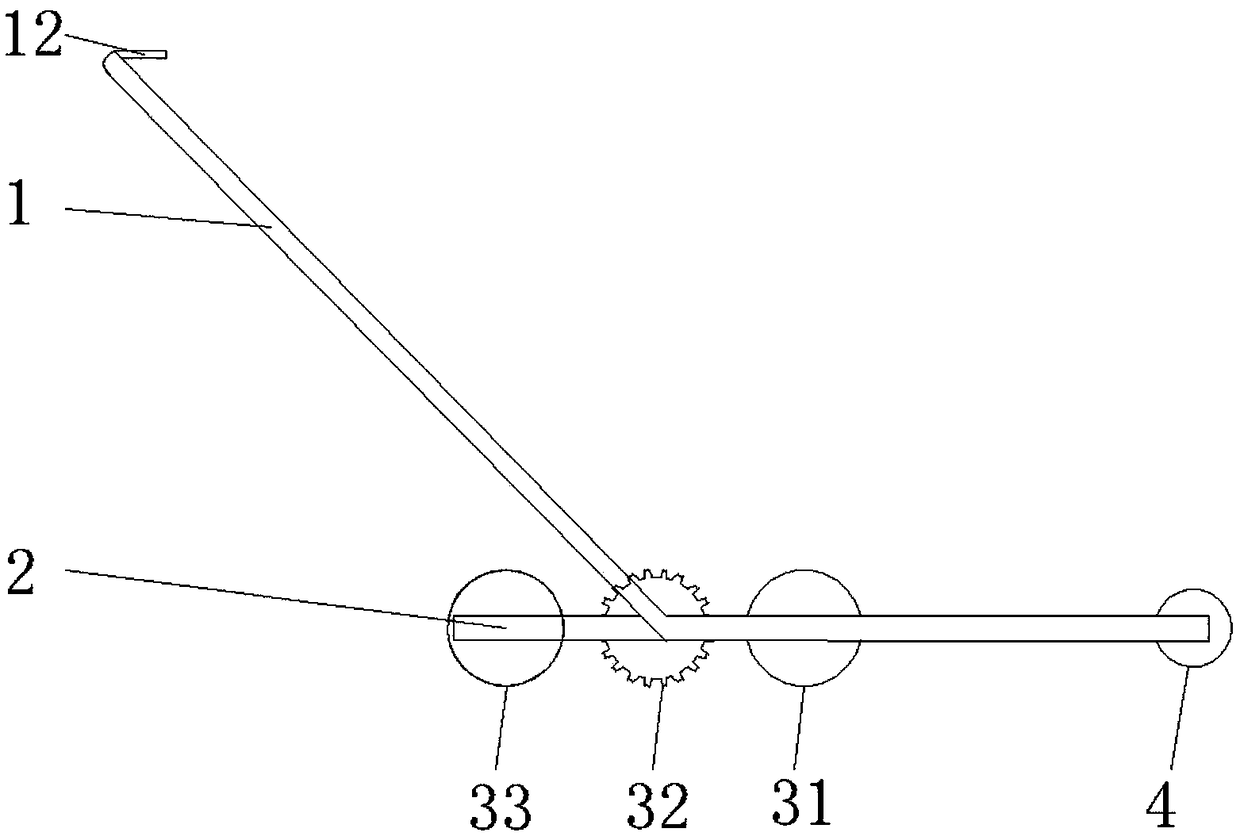

[0023] refer to Figure 1 to Figure 2 , this embodiment discloses an edge banding device for SBS modified asphalt waterproof membrane, including a bracket 1, a connecting rod 2, a pressing wheel 3, and a heating wheel 4;

[0024] The upper end of the bracket 1 is provided with an operating rod 11 , and the right end of the operating rod 11 is provided with a temperature indicator 12 and a regulating valve 13 ;

[0025] The pressure roller 3 includes a first roller pressure roller 31, a zigzag roller 32, and a second roller pressure roller 33, and is arranged in parallel between the connecting rods 2, and the pressing shaft of the pressure roller 3 is fixed on the connecting rod 2 superior.

[0026] A temperature sensor (not shown in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com