Skirt board edge-banding structure of skirt board edge-banding machine

An edge banding machine and coaming technology, which is applied in the field of coaming edge banding structure, welding cowl box coaming, and can solve the problem of scratching the surrounding article packaging, easily scratching the operator's skin, scratching Items and other issues, to achieve the effect of good edge banding quality, novel ideas, and high edge banding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

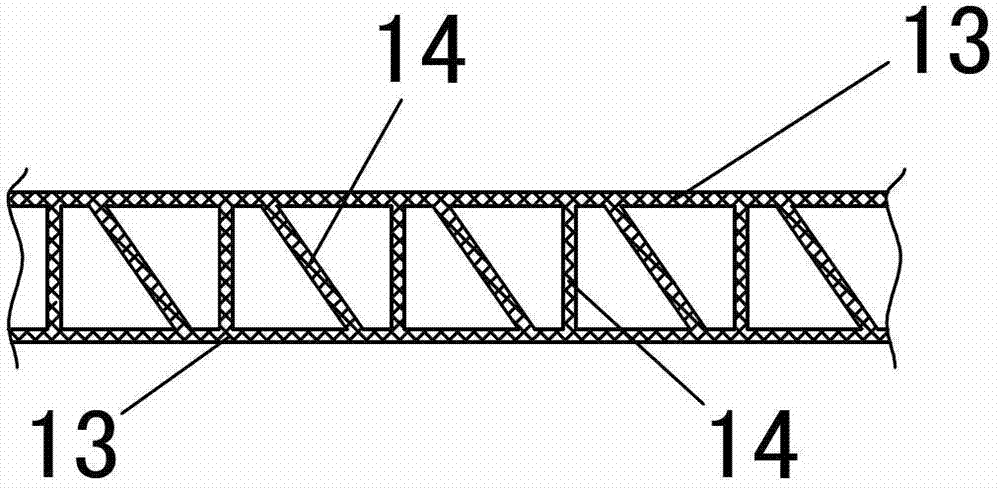

[0033] Embodiment 1: Single side edge banding structure of the coaming panel edge banding machine

[0034] See attached Figure 4 ~ attached Figure 6 As shown, a feeding device including a fuselage 15 and a conveying coaming 1, on the moving track of the coaming 1, a heating device, a crimping wheel assembly and an edge trimming device are sequentially arranged along the moving direction of the coaming 1; wherein:

[0035] The feeding device is composed of two pairs of traction rollers 2, two traction rollers 2 in each pair of traction rollers 2 are located on both sides of the coaming 1, the distance between the two traction rollers 2 is less than the thickness of the coaming 1, and at least one The root traction roller 2 is connected with the output shaft of a motor, and the coaming 1 is sent out through the static friction between the traction roller 2 and the coaming 1, and the distance between the two traction rollers 2 can be adjusted according to the width of the coam...

Embodiment 2

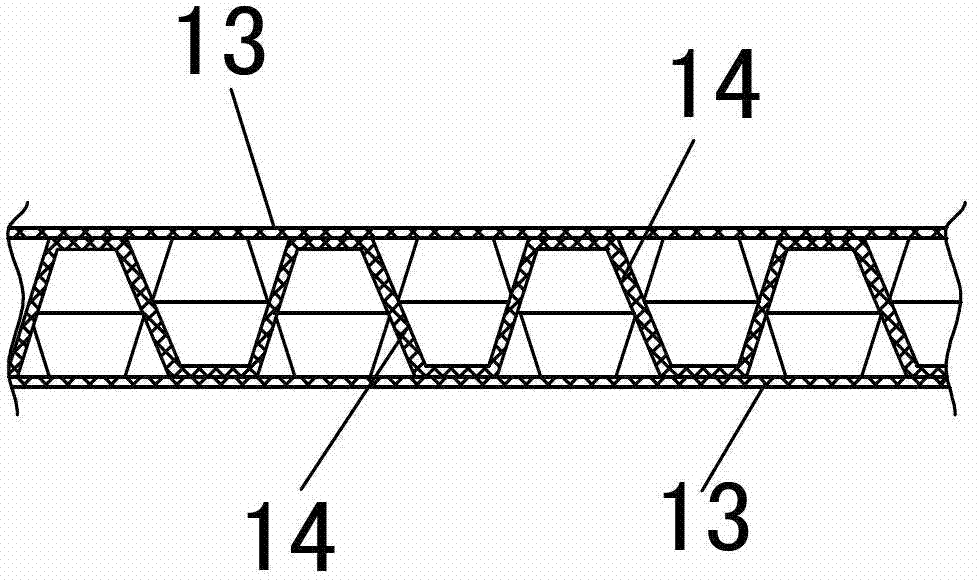

[0044] Embodiment 2: Double side edge banding structure of the coaming panel edge banding machine

[0045] See attached Figure 8 ~ attached Figure 10 As shown, a feeding device including a fuselage 15 and a conveying coaming 1, on the moving track of the coaming 1, a heating device 3, a crimping wheel assembly and an edge trimming device are sequentially arranged along its moving direction; wherein:

[0046] The feeding device is composed of two pairs of traction rollers 2, two traction rollers 2 in each pair of traction rollers 2 are located on both sides of the coaming 1, the distance between the two traction rollers 2 is less than the thickness of the coaming 1, and at least one The root traction roller 2 is connected with the output shaft of a motor, and the coaming 1 is sent out through the static friction between the traction roller 2 and the coaming 1, and the distance between the two traction rollers 2 can be adjusted according to the width of the coaming 1 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com