Porcelain molding cleaning equipment with remote control function

A technology for remote control and cleaning equipment, which is applied to auxiliary molding equipment, ceramic molding machines, manufacturing tools, etc. It can solve the problems of time-consuming, laborious, troublesome cleaning, and damage to porcelain, and achieve the effect of reducing the amount of manual labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

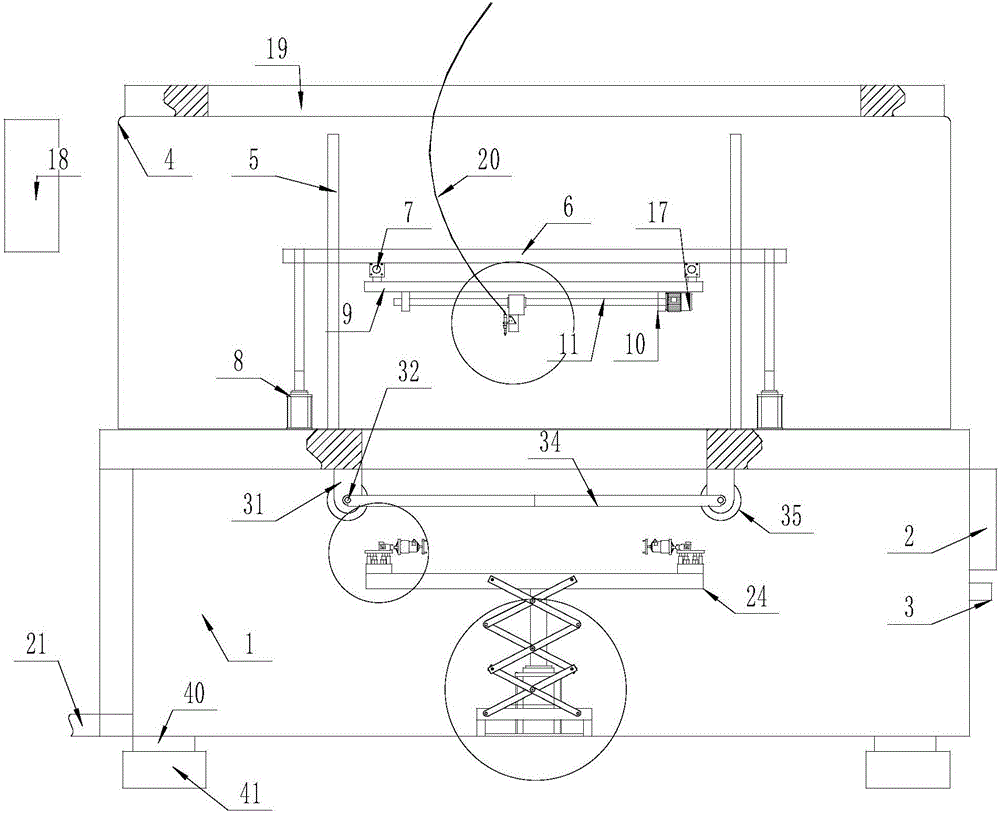

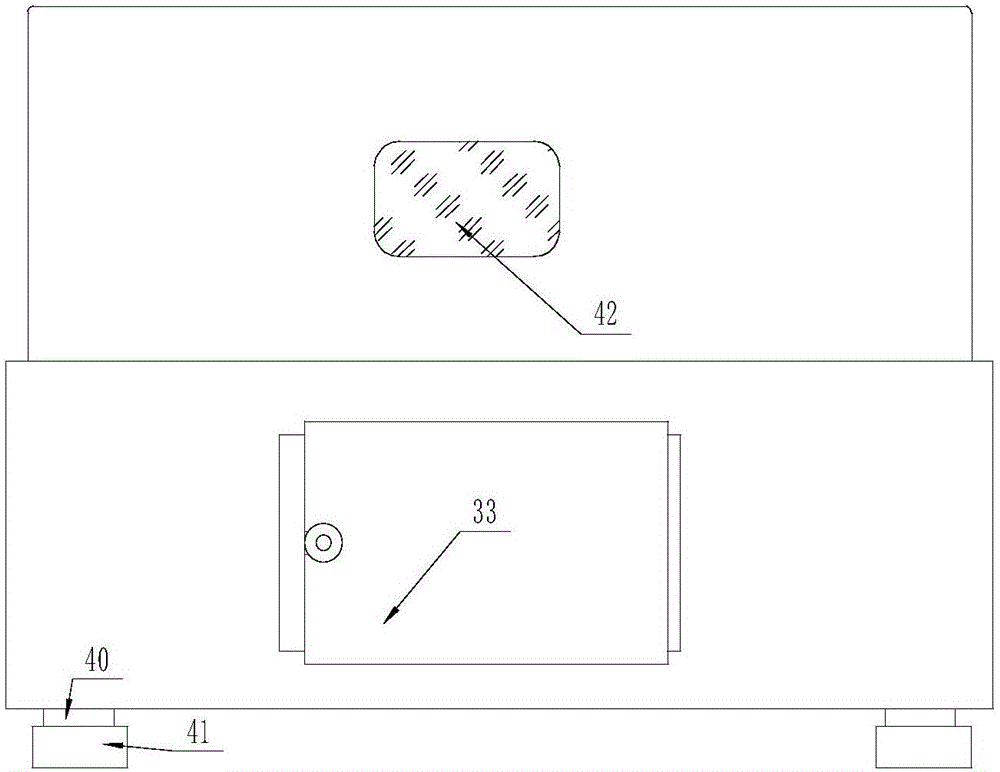

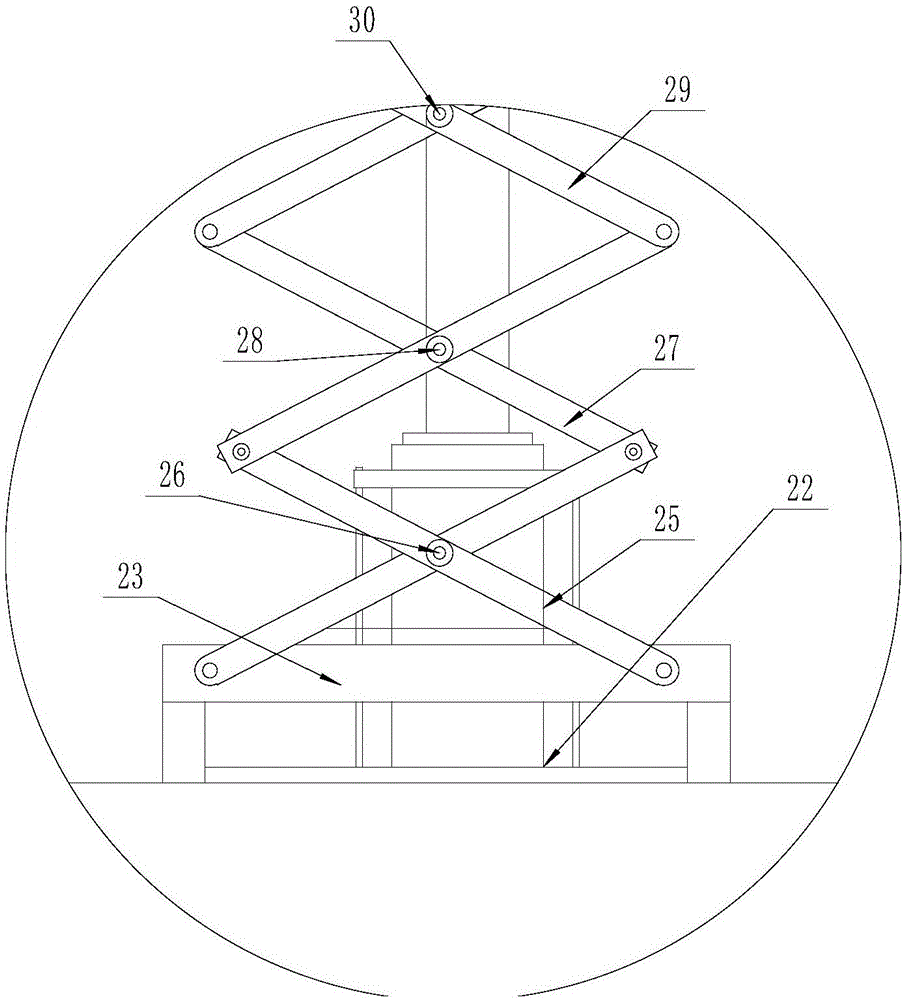

[0022] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5 As shown, a remote control porcelain forming cleaning equipment includes a machine platform 1, a microcontroller 2, a signal transmitter 3, and a protective cover 4 that matches the size of the machine platform 1, and the bottom surface of the machine platform 1 is fixed. The support structure, the cleaning mechanism and the clamping mechanism are fixed on the machine platform 1, the automatic feeding mechanism and the closing mechanism are arranged inside the said machine platform 1, and the feeding mechanism is arranged outside the said machine platform 1, and the said cleaning mechanism is made of The four guide columns 5 fixed on the upper end surface of the machine table 1, the moving plate 6 set on the four guide columns 5, are installed on the upper end surface of the machine table 1; and the cylinder 8 near its two ends, one end and the cylinder 8 The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com