Visual-positioning dispensing system and method

A visual positioning and dispensing technology, which is applied to coatings, devices that apply liquid to surfaces, etc., can solve the problems of low automation and low efficiency, and achieve high automation, reduce production costs, and improve product yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

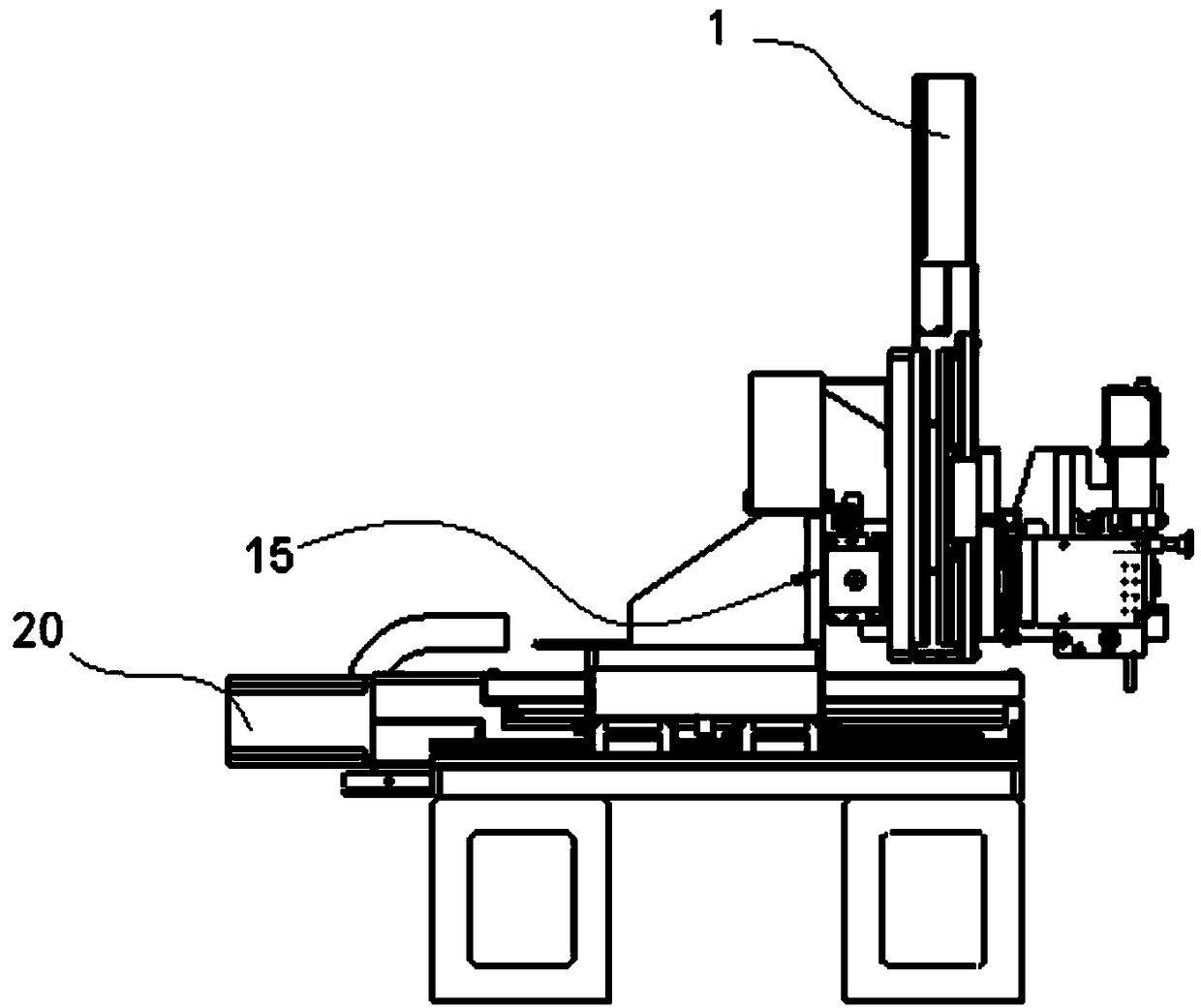

[0027] Such as Figures 1 to 4 As shown, a visual positioning dispensing system is used for automatic dispensing on the surface of sheet parts, including a camera mechanism, a dispensing mechanism, a three-axis mechanism, a computer and a controller.

[0028] Wherein, the camera mechanism includes a telecentric lens 4, a camera 3 arranged at the upper end of the telecentric lens 4, and a light source 5 arranged at the lower end of the telecentric lens.

[0029] The dispensing mechanism and the camera mechanism are fixed, and it has a rubber tube 6, an adapter connected with the controller signal is provided at one end of the rubber tube 6, and a needle 8 is provided at the other end. The rubber cartridge 6 is fixed by the knob 11 and the rubber cartridge abutment 12 , and the needle 8 is fixed on the needle adapter 7 .

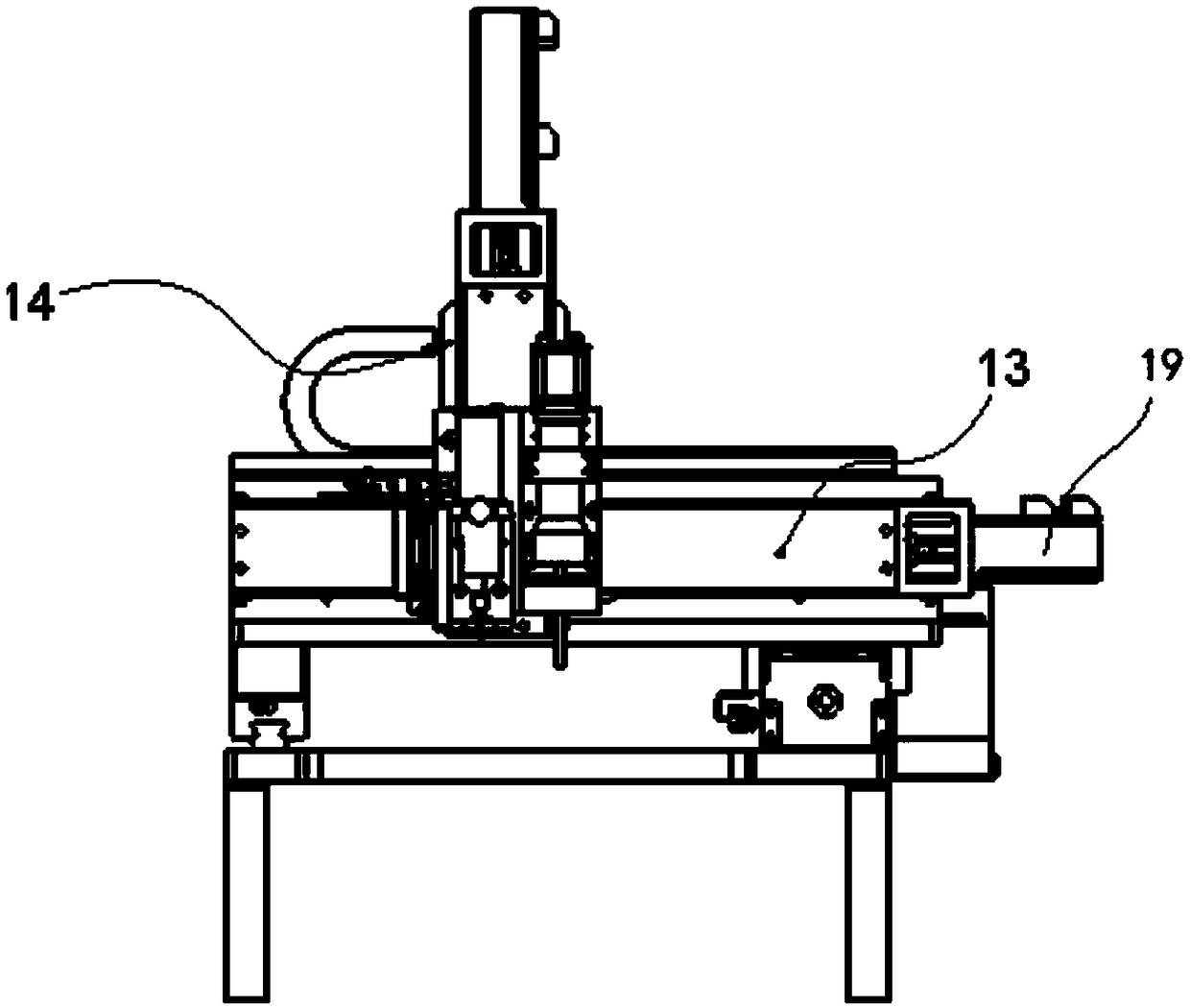

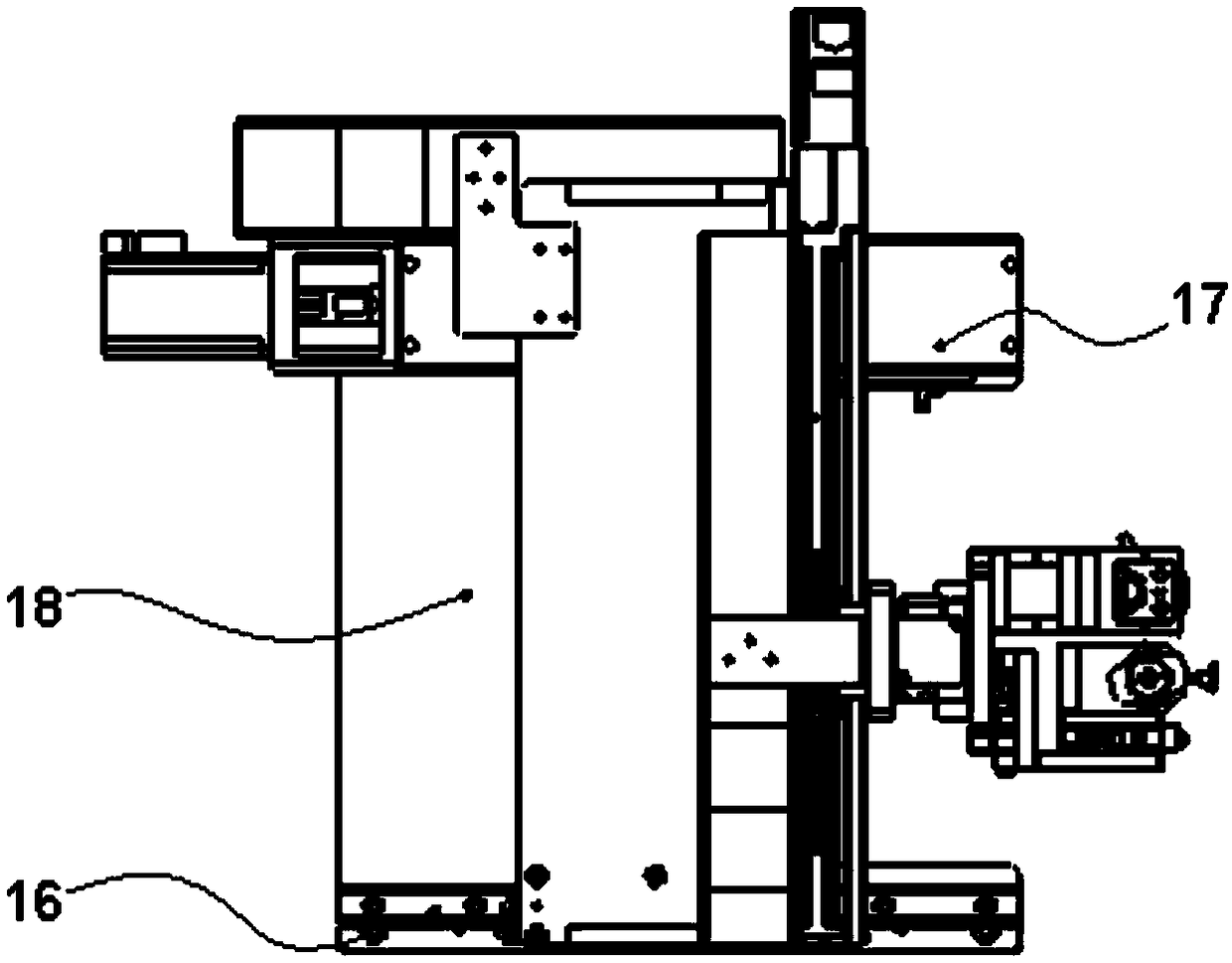

[0030] The three-axis mechanism includes a frame body 18 , x-axis modules 13 , y-axis modules 17 , z-axis modules 2 arranged on the frame body 18 and perpend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com