Automatic multi-station carbon brush assembly machine

An assembly machine and multi-station technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve problems such as manual assembly troubles, affecting the quality of carbon brushes, easy to drop, etc., to reduce detection time and reduce manual labor Quantity, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below with reference to specific embodiments.

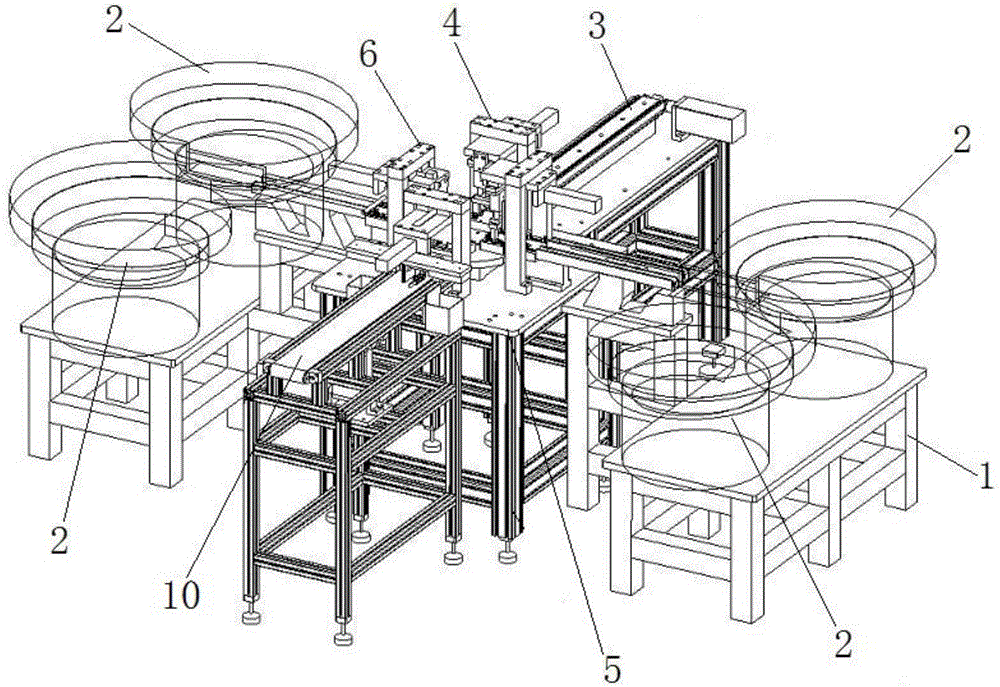

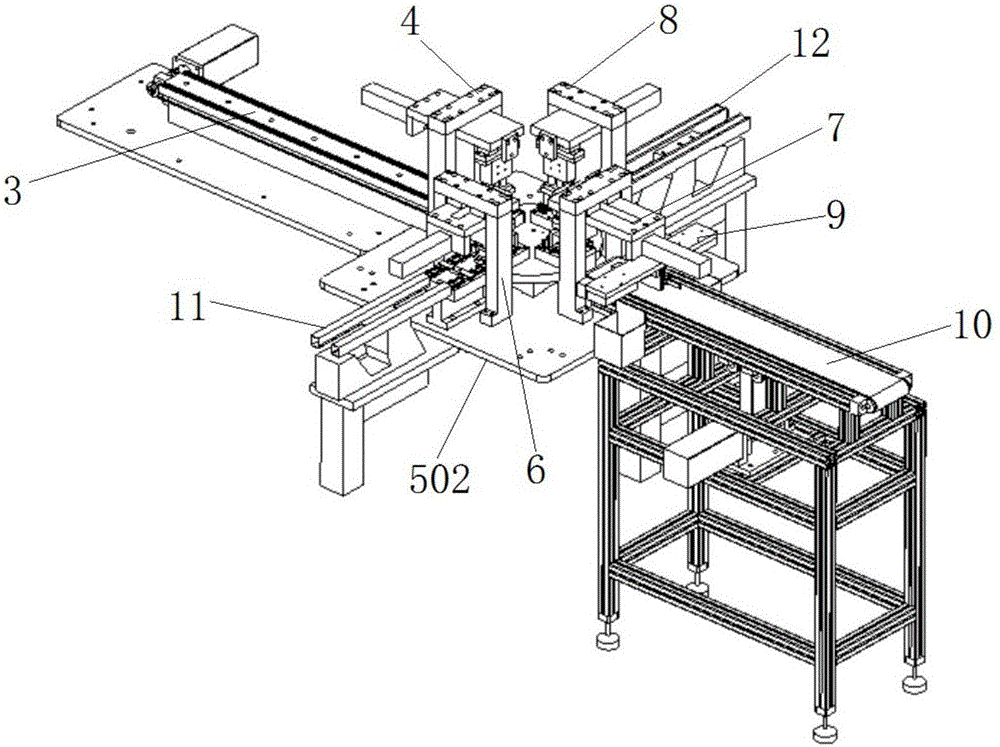

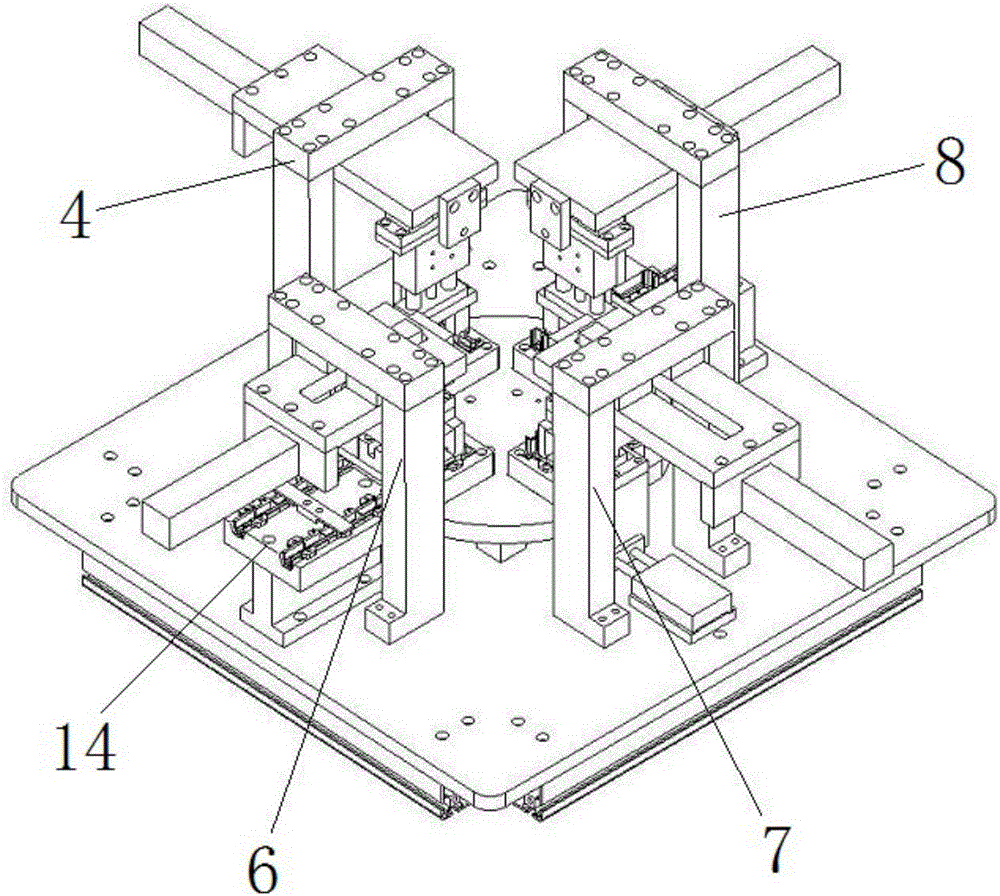

[0031] like Figure 1 to Figure 13 As shown, a multi-station carbon brush automatic assembly machine includes a frame, an indexing plate 5022 for positioning the carbon brush components 13, a feeding device for supplying the carbon brush components 13, and a carbon brush component for assembling the carbon brush components 13. The first assembly station 6, the second assembly station 4, the third assembly station 8 and the fourth assembly station 7 for the inspection of carbon brush finished products are connected to the The feeding device 10, the first assembly station 6, the second assembly station 4, the third assembly station 8 and the fourth assembly station 7 all include a bracket, a slider horizontally arranged on the bracket, and a drive connecting the drive slider The device, the lifting platform provided on the sliding seat, and the mechanical claws arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com