Full-automatic board separating machine

A splitter, fully automatic technology, used in metal processing and other directions, can solve the problems of unstable positioning of circuit boards, small moving range of cutting tools, and single cutting tools.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

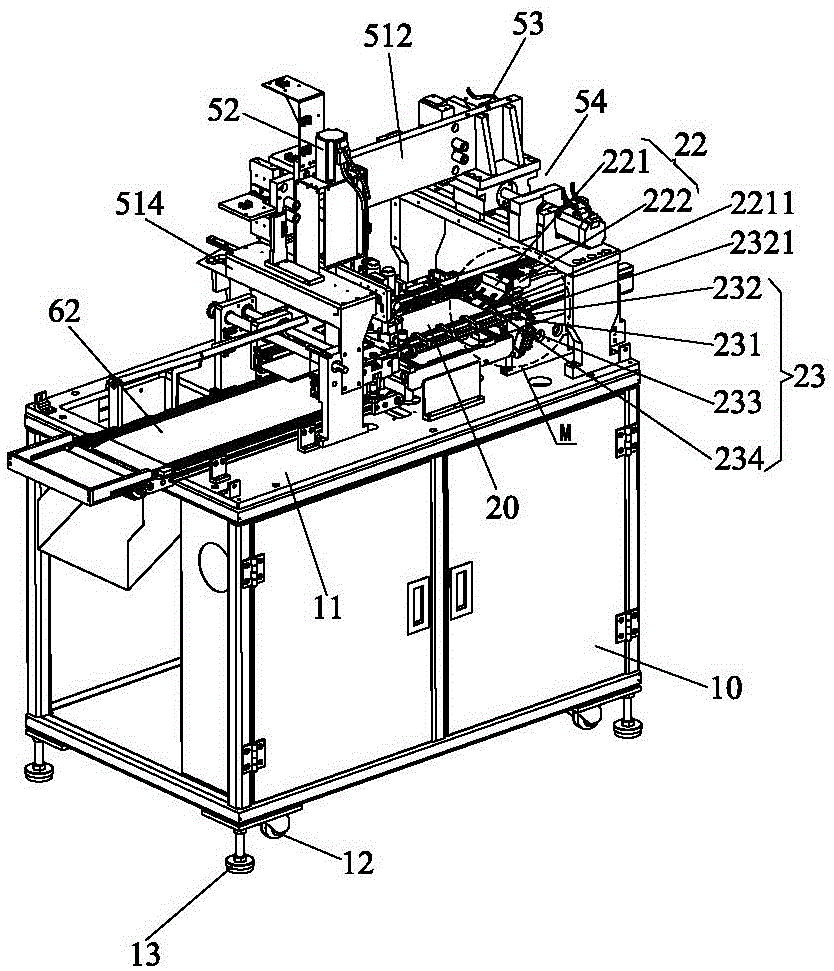

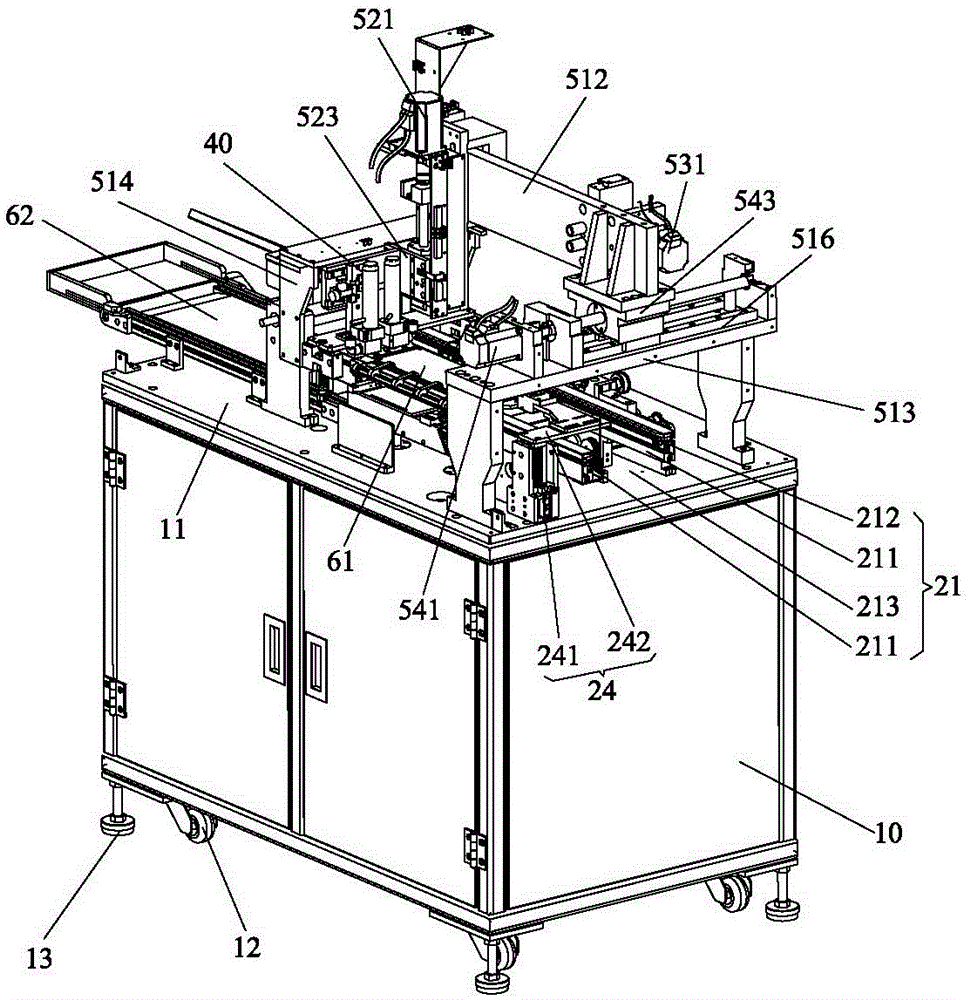

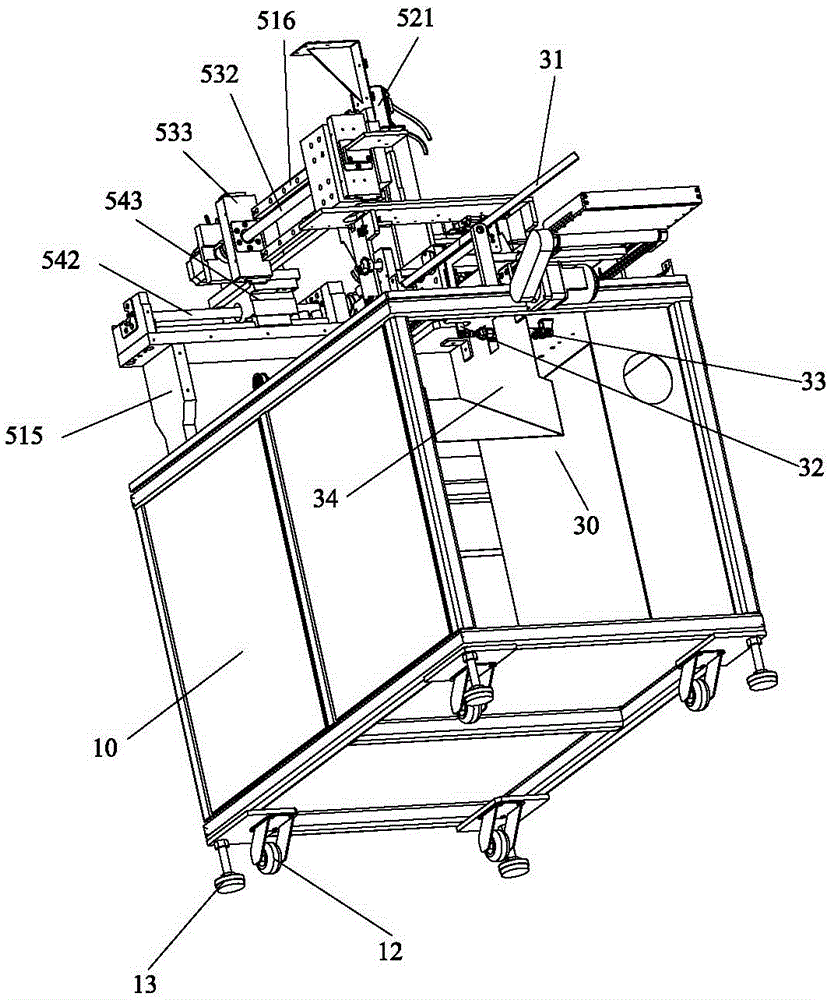

[0060] The present invention as Figure 1 to Figure 7As shown, a fully automatic board splitting machine includes an organic base 10, a feeding device 20 for transporting circuit boards to be cut, a waste collection mechanism 30 for collecting cutting waste, a cutting knife 40, and is used to drive the cutting knife 40 to move The mobile device 50 and the transfer device 60 for transferring the cut circuit board, wherein:

[0061] The machine base 10 is provided with a workbench 11 for installing the above-mentioned devices, and a roller 12 and a leg 13 are provided at the bottom of the machine base 10 .

[0062] The feeding device 20 includes a conveying mechanism 21, two clamping mechanisms 22 for clamping the two ends of the circuit board to be cut, two clamping mechanisms 23 for pressing the edges on both sides of the circuit board to be cut, and two clamping mechanisms 23 for driving the clamping mechanism 22. The lifting mechanism 24 that moves up and down, the conveyin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com