Charged coupled device (CCD) automated detecting device for connector

An automatic detection and connector technology, which is used in packaging automatic control, instruments, measuring devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

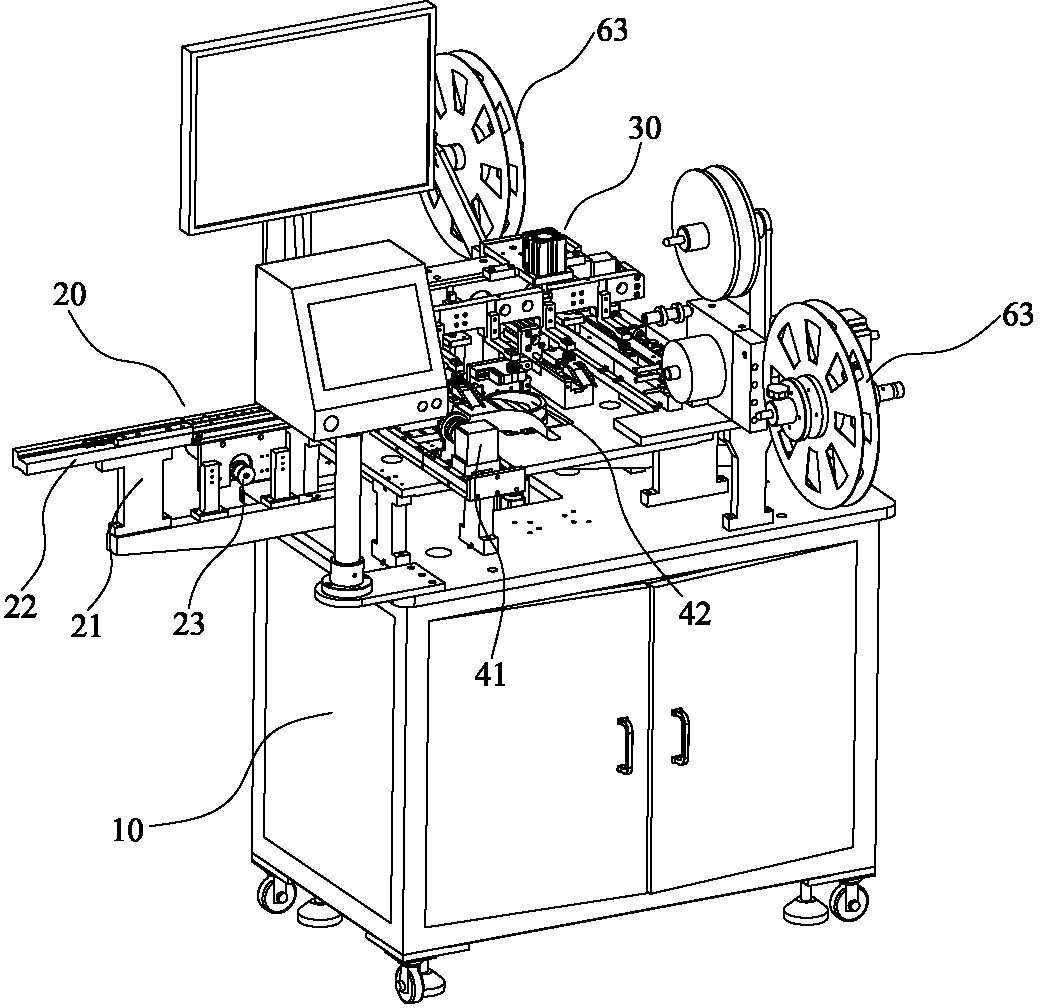

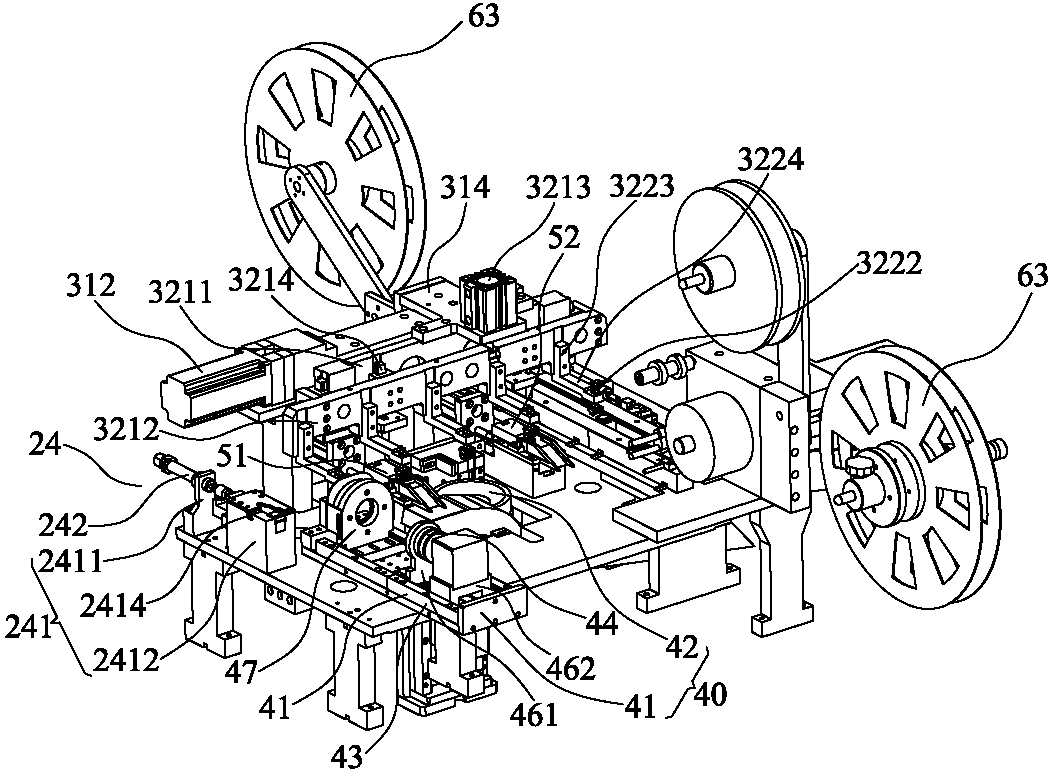

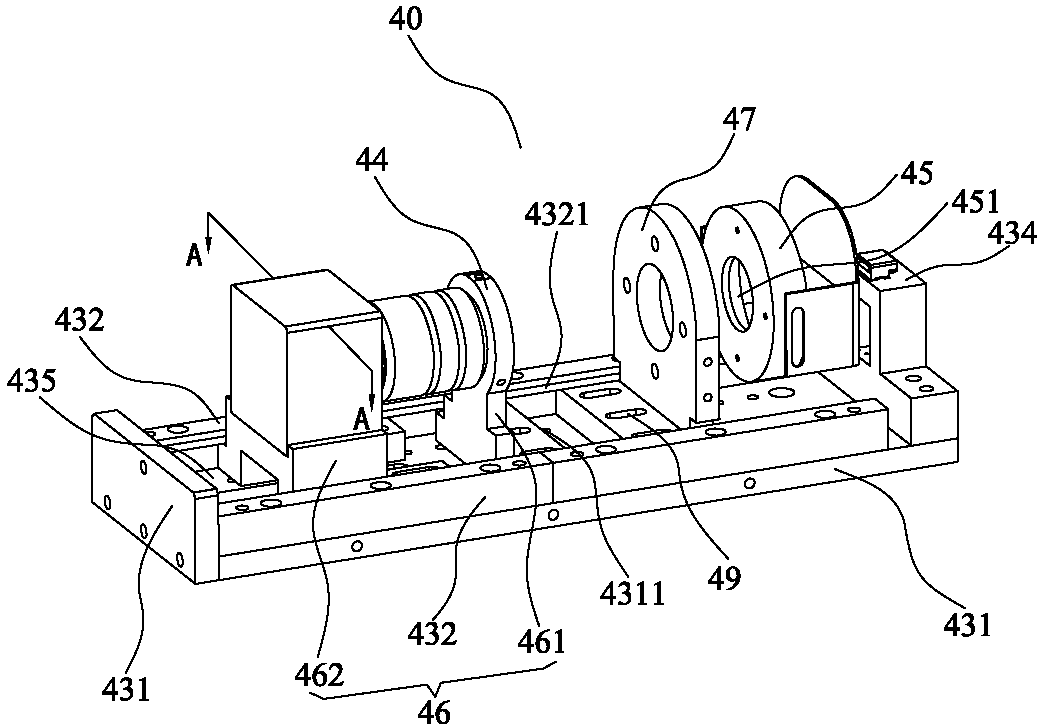

[0064] The present invention as Figure 1 to Figure 12 As shown, a CCD automatic detection equipment for connectors, which includes an equipment base 10 and a feeding device 20 arranged on the equipment base 10, a moving device 30, a CCD detection device 40, a defective product pushing device 50 and a good product packaging device 60, of which:

[0065] The feeding device 20 includes a bracket 21, a feeding rail 22 arranged on the top of the bracket 21, a transmission mechanism 23 for driving the feeding rail 22, and a pushing mechanism 24. The bracket 21 is fixed on the side wall of the above-mentioned equipment base 10. The mechanism 23 is installed on the bracket 21, the pushing mechanism 24 includes a pushing base 241, a pushing cylinder 242 and a pushing piece 243, and the pushing base 241 includes a pushing cylinder support seat 2411 and a pushing piece supporting Seat 2412, the pusher cylinder 242 is installed on the pusher cylinder support seat 2411, a pusher guide gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com