Automatic CCD detecting device

An automatic detection and equipment technology, applied in the field of automation, can solve problems such as high dependence on operators, confusion between good and defective products, and error-prone product screening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

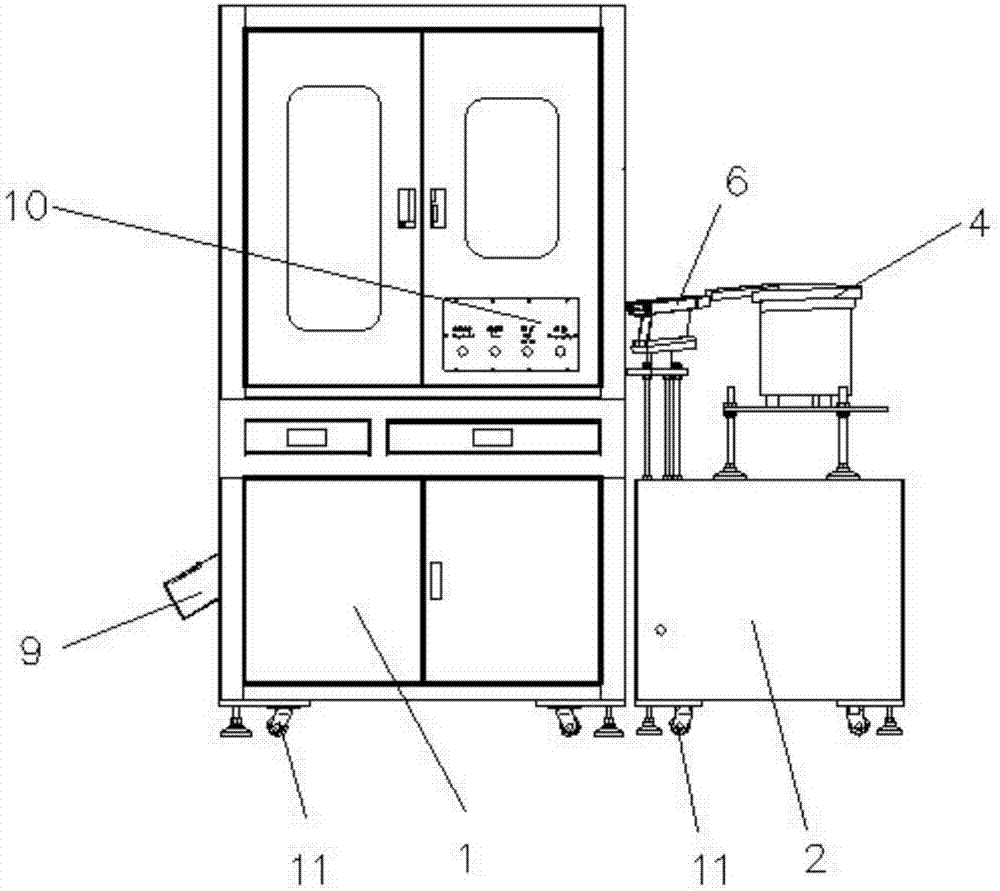

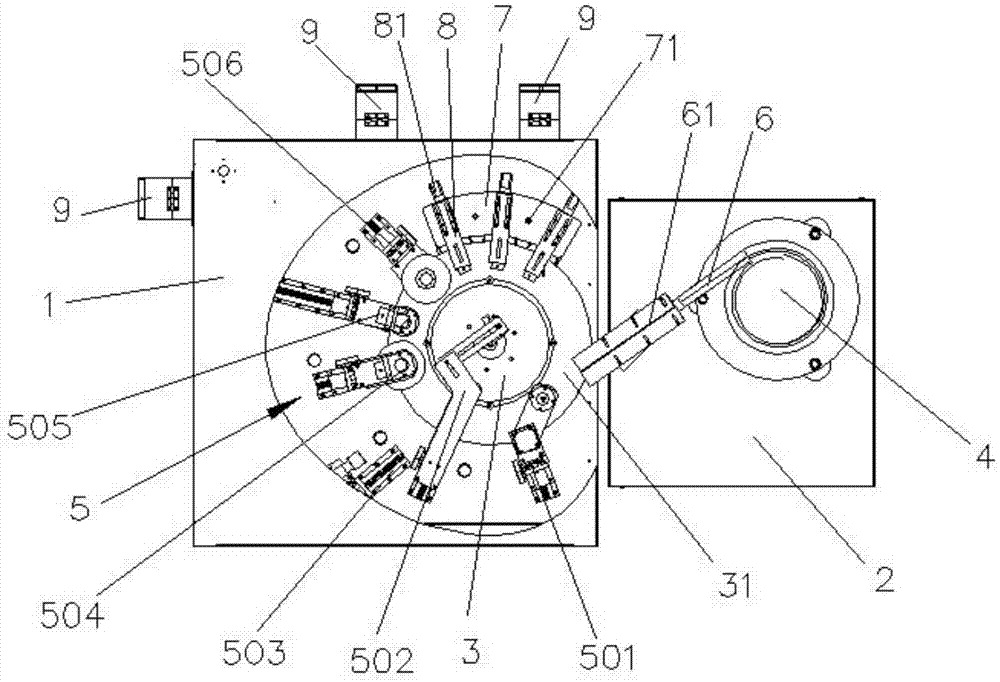

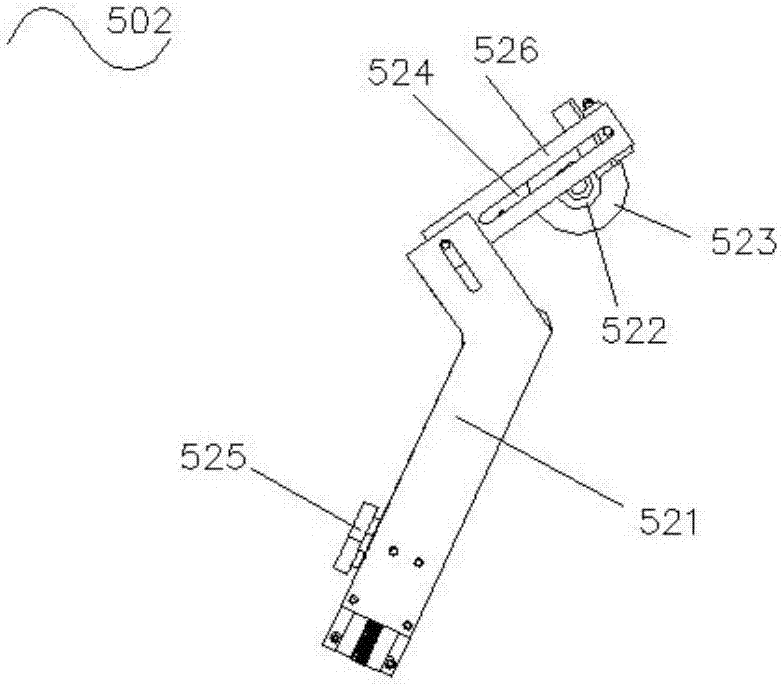

[0023] see Figure 1 to Figure 3 , a kind of CCD automatic detection equipment provided by the present invention, comprises equipment base 1, vibrating disc base 2, workbench turntable 3, vibrating disc 4, CCD detection device assembly, feeding trough 6 and discharge box 7, described workbench turntable 3 is set on the equipment base 1, the vibration plate 4 is set on the vibration plate base 2, the equipment base 1 and the vibration plate base 2 are juxtaposed, and the vibration plate 4 is connected to the worktable turntable 3 through the feeding groove 6 , the feeding chute 6 is tangent to the head end of the worktable turntable 3, the CCD detection device assembly is arranged on the equipment base 1, the CCD detection device assembly 5 includes at least four CCD detection devices, and the CCD detection device assembly 5 includes at least four CCD detection devices. The devices are irregularly distributed along the workbench turntable 3, the CCD detection device includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com