Cigarette case packaging detection process

A cigarette case and packaging technology, which is applied in the field of cigarette case packaging inspection technology, can solve the problems of undetectable waste products, defects in the appearance of cigarette cases, and low detection efficiency, so as to improve detection efficiency and detection accuracy, and improve the rejection rate of defective products , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

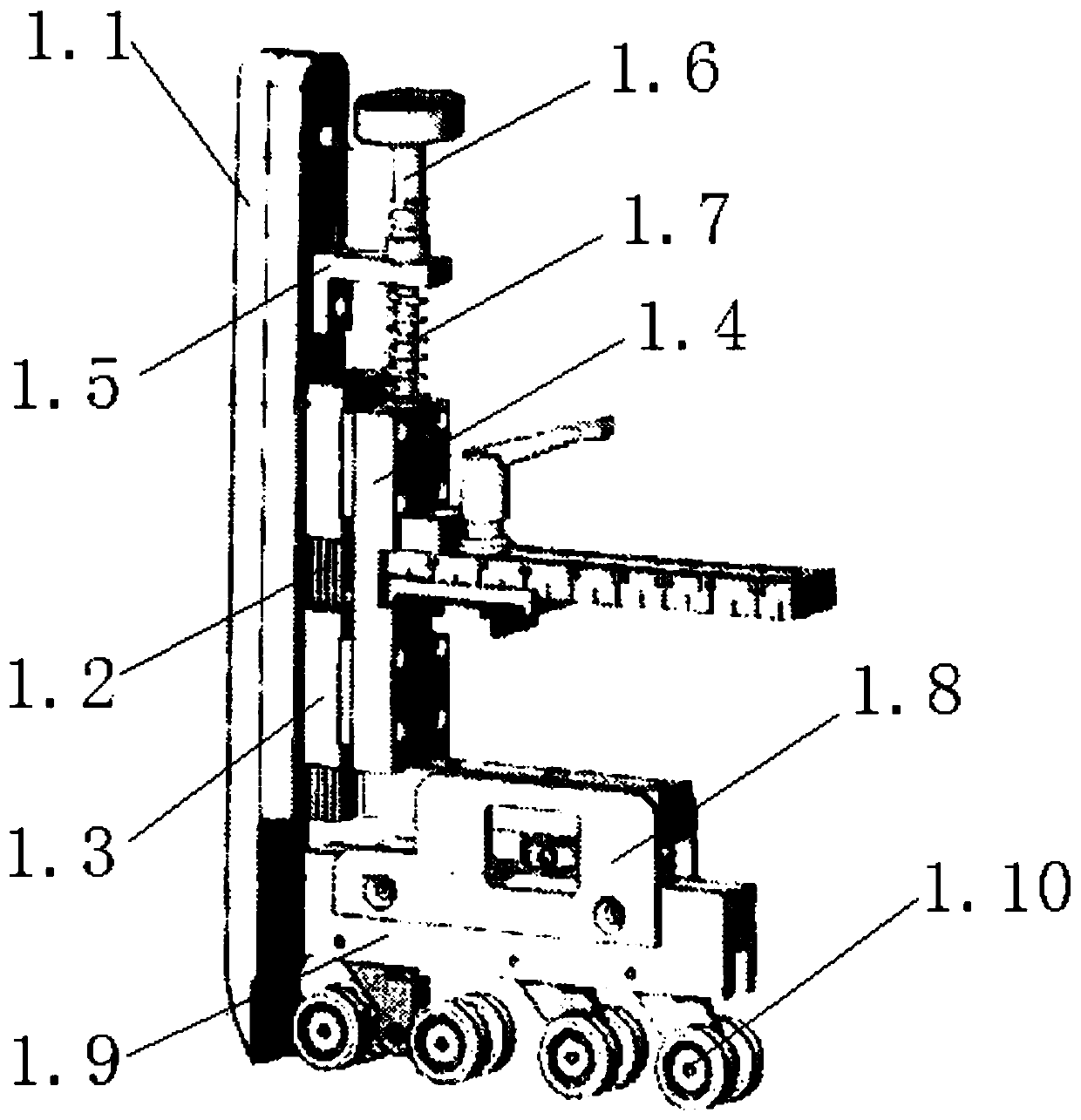

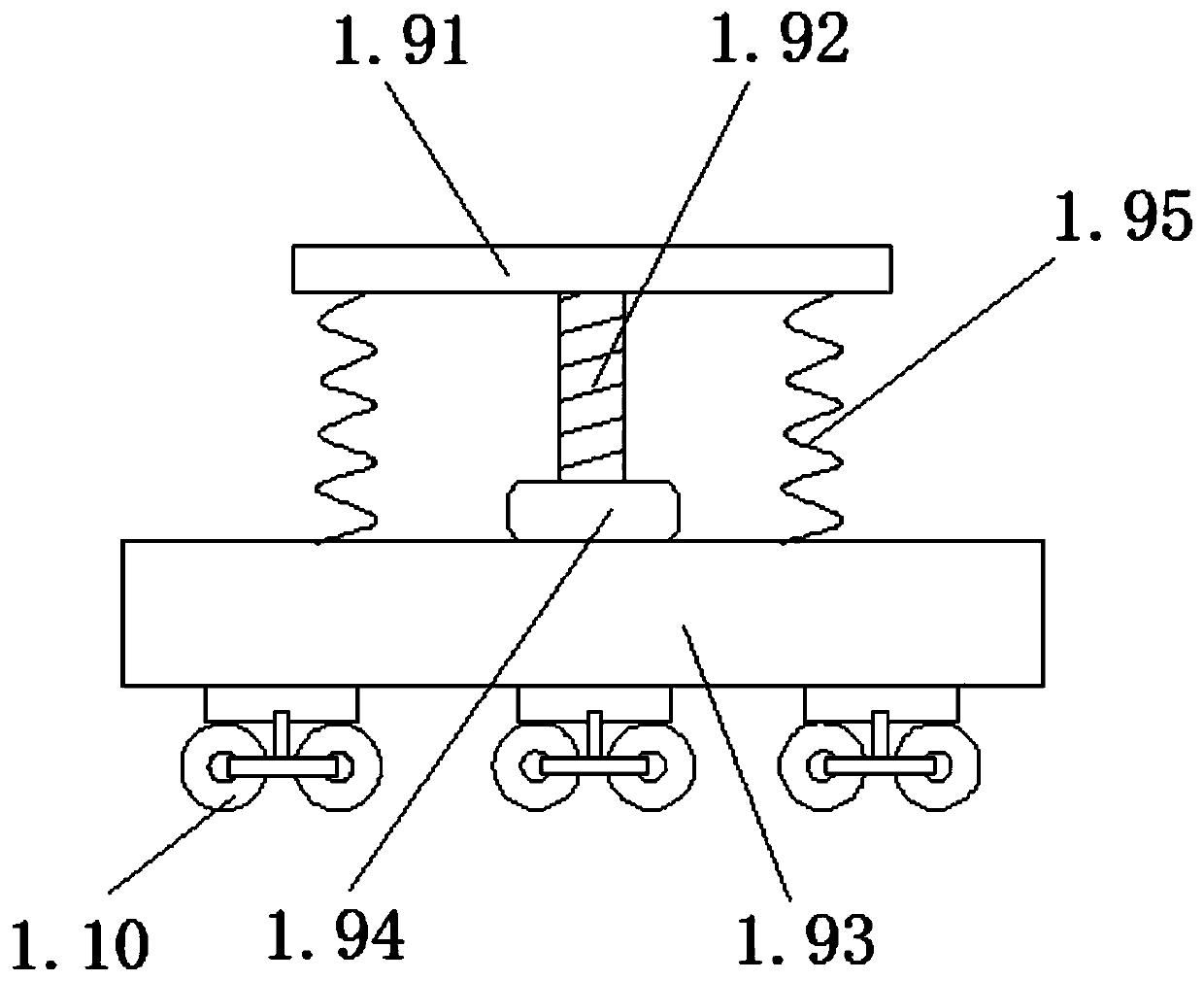

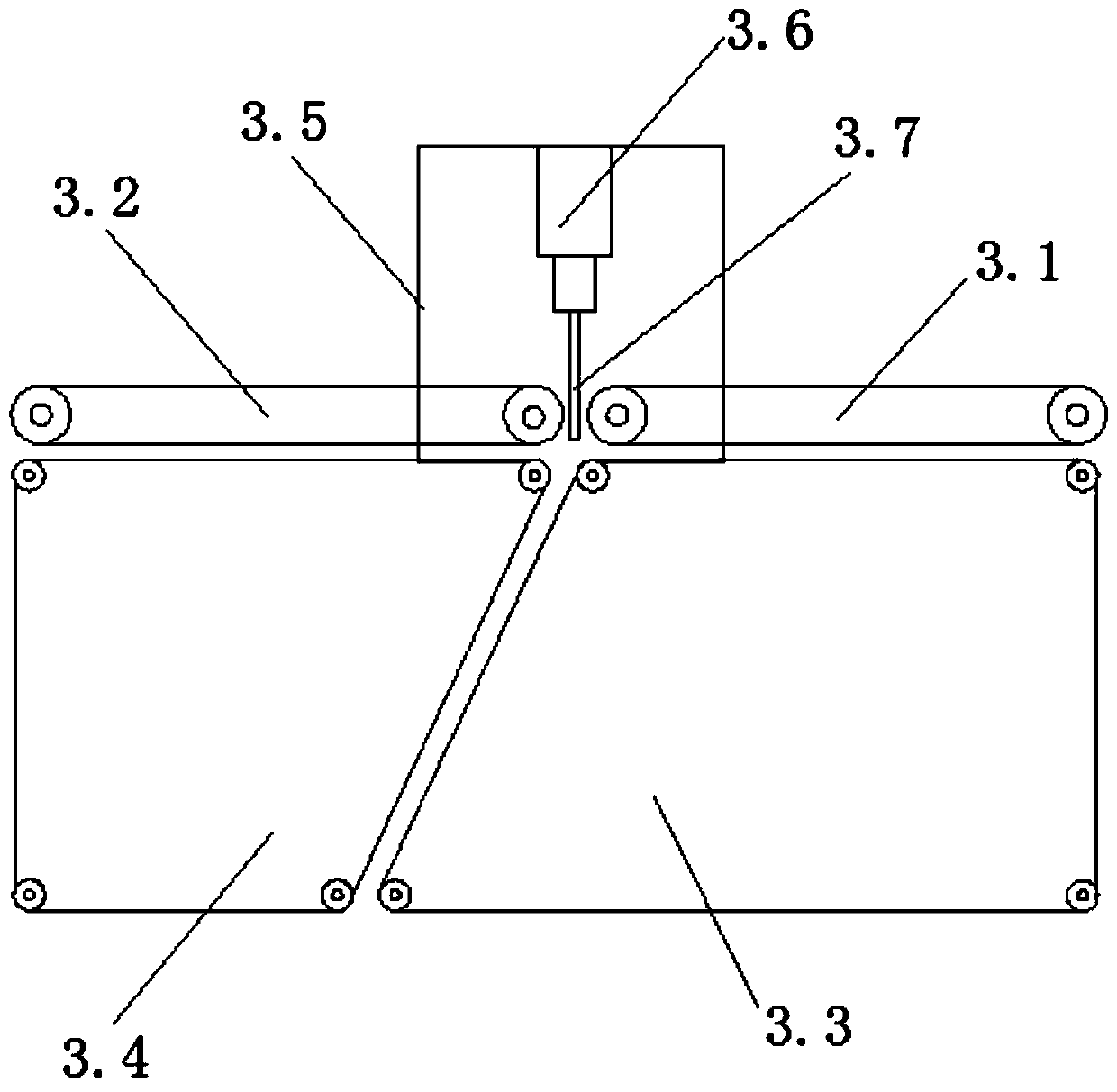

[0030] see Figure 1~6 , a kind of cigarette case packaging detection process that the present invention relates to, described process step is:

[0031] Step 1. Stack the wrapping papers of cigarette packs to be tested in front of the paper feeding mechanism 1, and adjust the distance between the working surface of the cutter head of the paper feeding knife 1.1 and the conveyor belt to an appropriate position to ensure that only one piece of wrapping paper can pass through each time. , the wrapping paper starts to be transported forward one by one at intervals;

[0032] Step 2. When the packaging paper to be inspected is transported to the detection mechanism 2, the CCD camera and the spotlight installed inside are all facing the packaging paper, and the printing and die-cutting parts of each packaging paper being transported on the conveyor belt are monitored in real time. Take pictures, and transmit the captured inspection photos to the central processing unit, and compare ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com