Intelligent laser welding system and operation method thereof

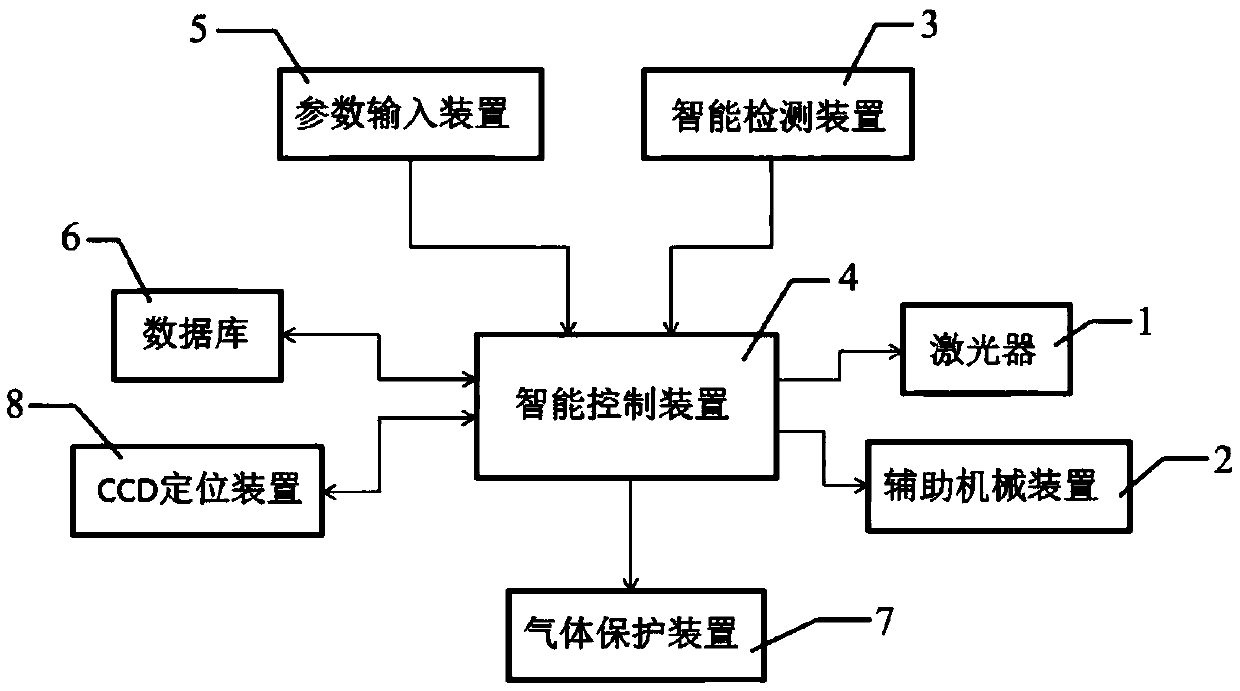

A laser welding and intelligent technology, applied in the direction of laser welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of difficult mechanization development, slow welding speed, unsightly appearance, etc., and achieve real-time monitoring of welding, high welding quality and high safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

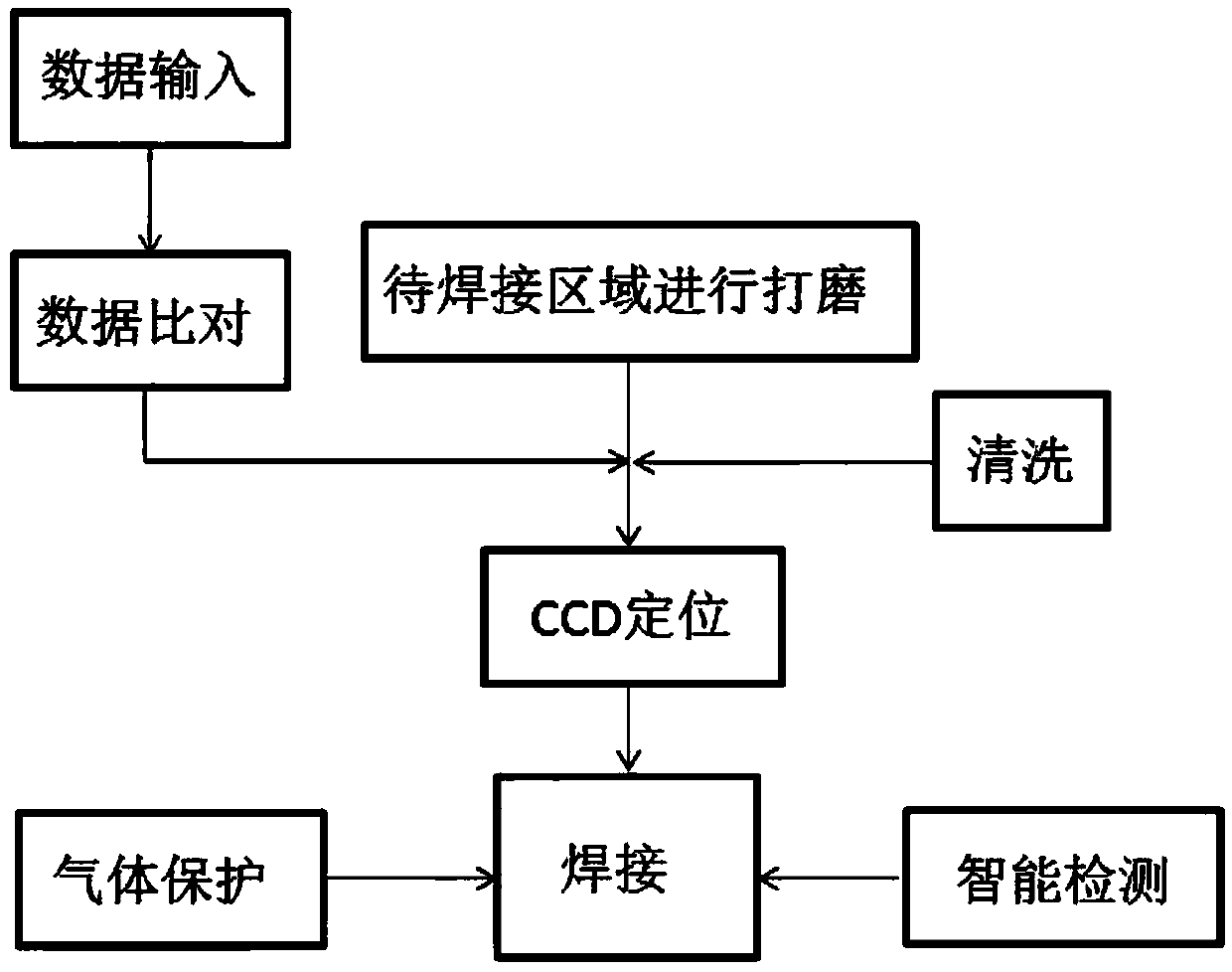

Method used

Image

Examples

Embodiment 1

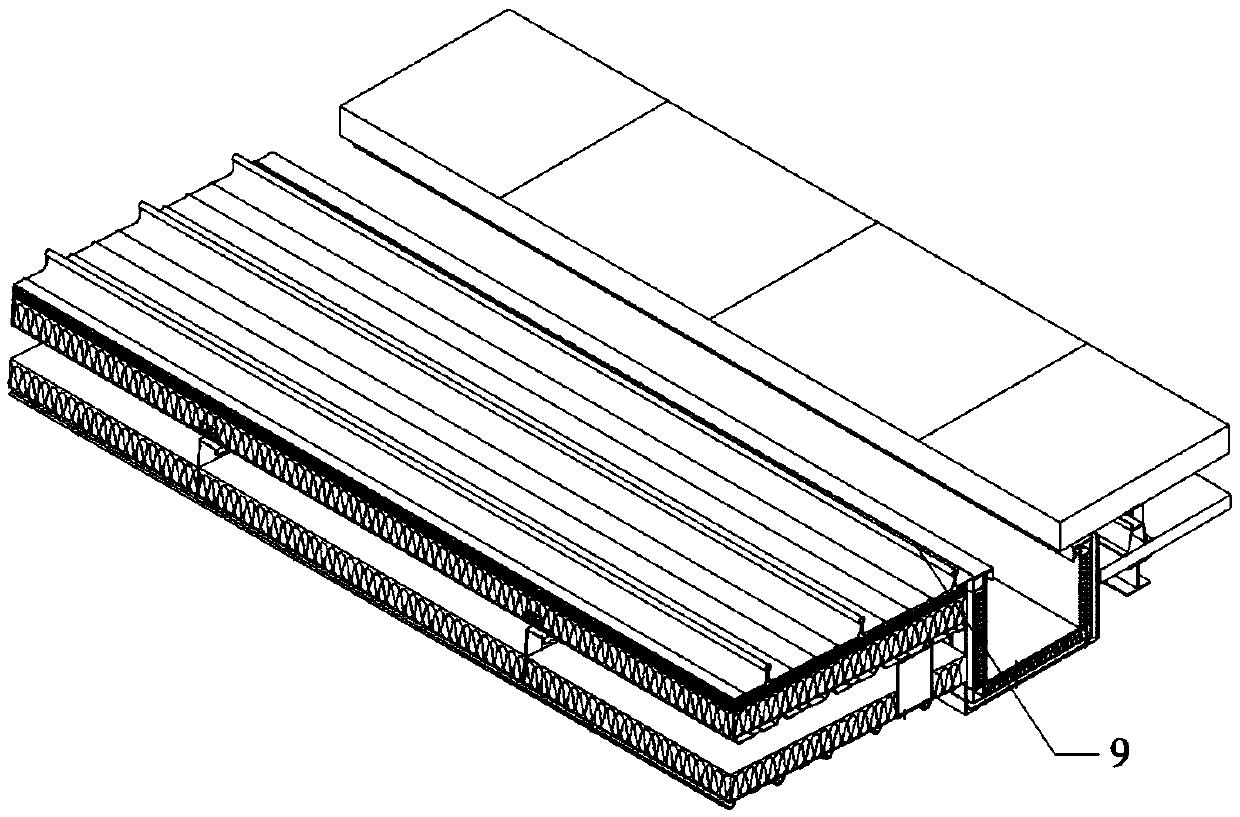

[0044] For welding of aluminum magnesium manganese roof panels such as image 3 shown.

[0045] The first step is to polish the welding surface of the aluminum-magnesium-zinc roof panel according to the welding area 9 required by the design drawings, and then clean the side with acetone to remove surface oil;

[0046] In the second step, use the CCD positioning device 8 to locate the end of the lapped stainless steel tube to be packaged, adopt a pulsed fiber laser 1 with a wavelength of 1080nm, and turn on the argon shielding gas for welding; when welding, the laser frequency is 10K, The spot diameter ratio of the output power is 1000w / mm, the scanning line speed is 8mm / s for welding, the shielding gas is argon, the flow rate is 10L / min, and the shielding gas nozzle is 4mm away from the upper processing surface;

[0047] The third step is to use a high-speed camera to collect welding images and ultrasonic flaw detection, locate the welding position in time and give real-time ...

Embodiment 2

[0050] Butt welding for gutters such as Figure 4-5 shown.

[0051] The first step is to polish the butt joint area of the stainless steel gutter to be welded in area 9, and clean it with acetone.

[0052] The second step is to butt two stainless steel plates according to the drawing design requirements.

[0053] The third step is to use the CCD positioning device 8 to locate the place to be welded on the stainless steel plate after the butt joint, and adopt continuous CO with a wavelength of 10600nm 2 Laser 1, and turn on the mixed protective gas of argon and helium for welding; when welding, the spot diameter ratio of the output power is 8000w / mm, the scanning line speed is 300mm / s, the flow rate of the protective gas is 15L / min, and the protective gas nozzle 20mm from the upper surface of the machine;

[0054] The fourth step is to use a high-speed camera to collect welding images and ultrasonic flaw detection, locate the welding position in time and give real-time fee...

Embodiment 3

[0057] The welding method of roof purlins is as follows: Figure 6 shown.

[0058] In the first step, according to the requirements of the drawings, the welding contact surface of the welding area 9 is polished, and then the side is cleaned with acetone to remove surface oil;

[0059] In the second step, use the CCD positioning device 8 to position the end of the clamped stainless steel tube to be packaged, use a solid-state continuous laser 1 with a wavelength of 600nm, and turn on the shielding gas for welding; the spot diameter ratio of the output power is 1666w / mm , the scanning line speed is 25mm / s welding, when welding, the shielding gas is argon, the flow rate is 5L / min, and the shielding gas nozzle is 12mm away from the upper processing surface;

[0060] The third step is to use a high-speed camera to collect welding images and ultrasonic flaw detection, locate the welding position in time and give real-time feedback on the quality of the weld, and repair it in time i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com