Environment-friendly type composite grain scalping machine

A kind of grain cleaning and environmental protection technology, applied in the direction of sieves, grilles, and the separation of solids from solids by airflow, which can solve the problems of insufficient dust removal, hidden dangers of grain storage, and poor dust removal effect, etc. To achieve the effect of reducing the amount of manual labor, high work efficiency, and reducing the risk of mildew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

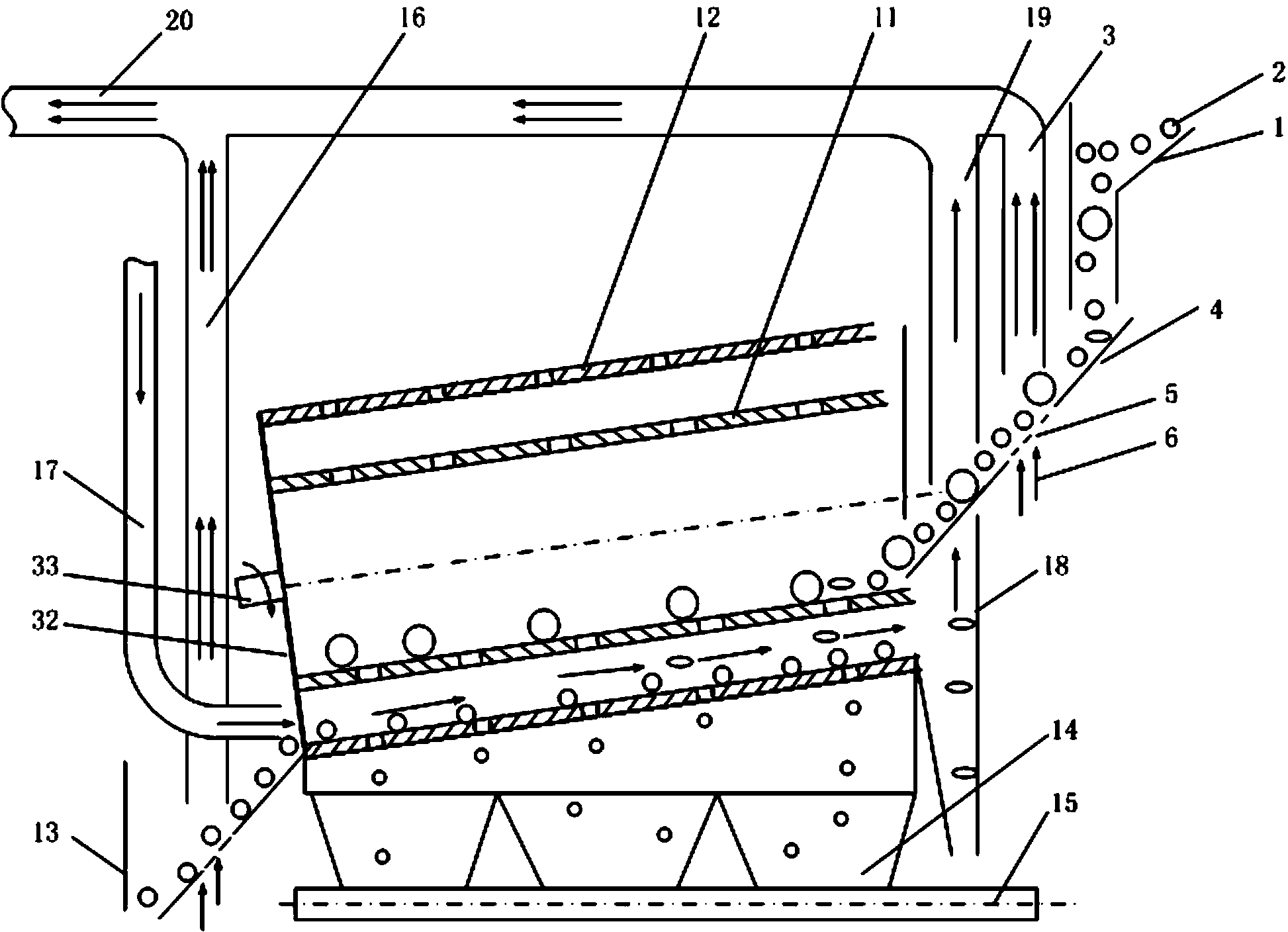

[0035] The present invention is an improvement on the basis of the existing cylindrical sieve type grain cleaning machine, and the main improvements include the following parts:

[0036] 1. Wind separation dust removal unit

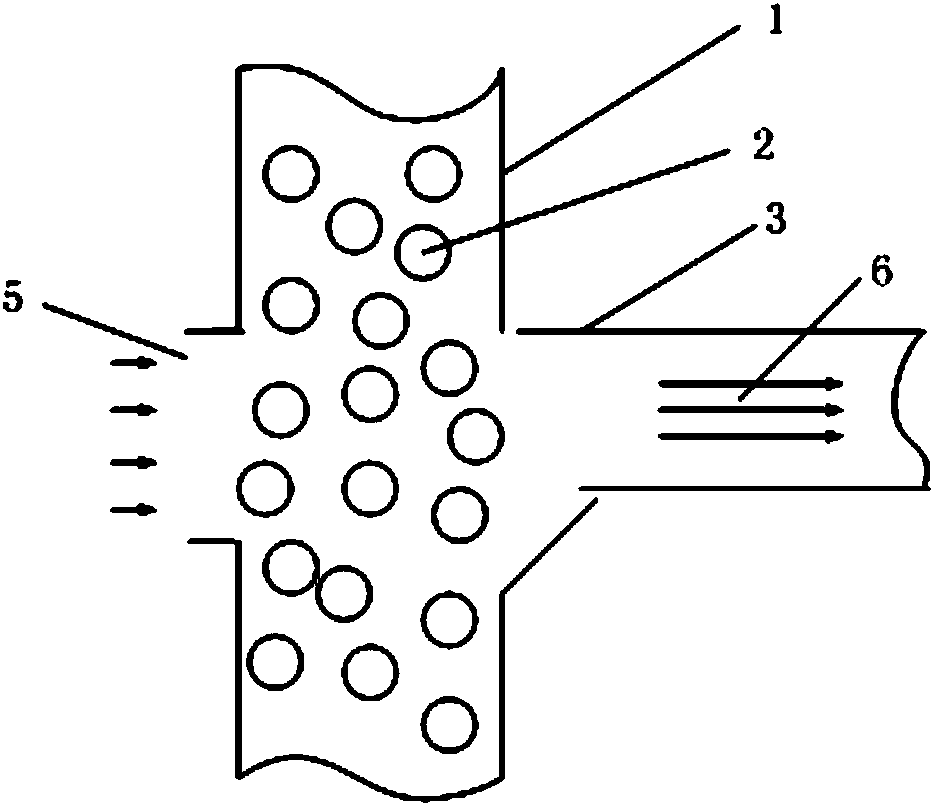

[0037] The traditional winnowing dust removal adopts the vertical free fall of the grain, and the dust removal port of the winnowing equipment is facing the falling grain, such as figure 1 As shown, the grain particles 2 in the feed hopper 1 fall freely, and a negative pressure air duct 3 is provided in the direction perpendicular to the grain drop to suck away the dust in the grain. The position is provided with air inlet 5. This method causes incomplete dust cleaning due to the blocking effect in the falling of grain.

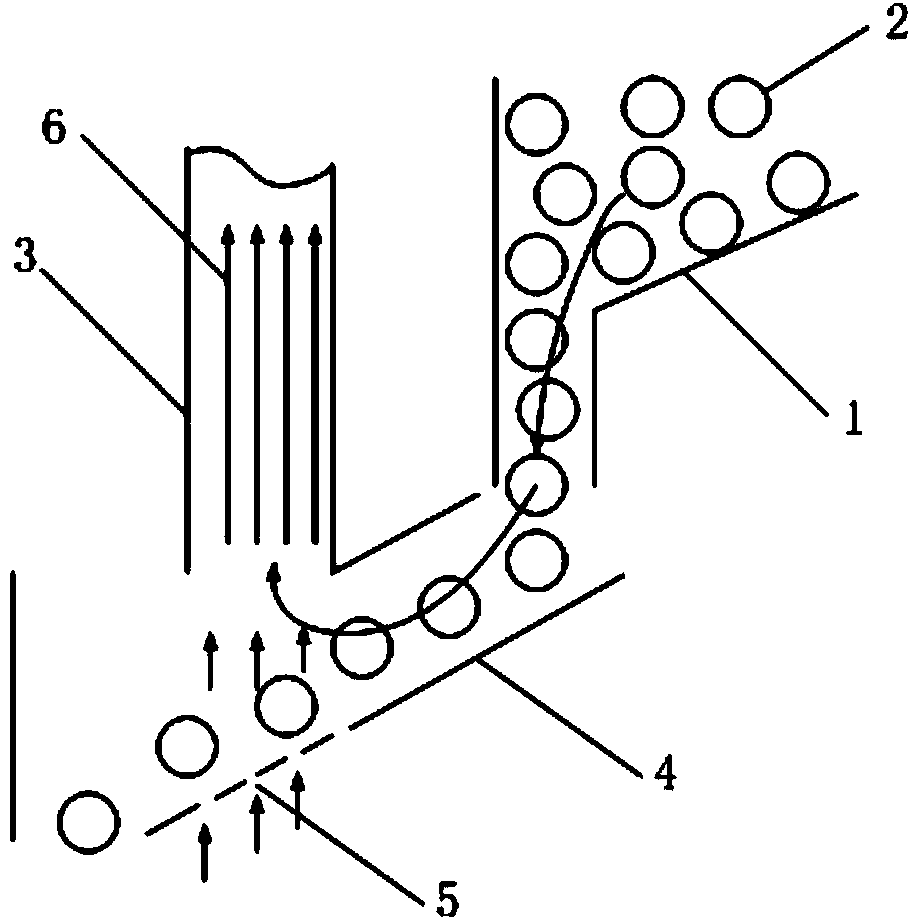

[0038] Wind separation dust removal device of the present invention such as figure 2 As shown: the outlet of the feed hopper 1 is flat, and the grain particles 2 are laid on the inclined wall of the receiving hopper 4 in a thin layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com