Fabric tailoring table with cleaning device

A cleaning device and cutting table technology, applied in the cutting of textile materials, textiles and papermaking, metal processing, etc., can solve the problems of affecting the cutting operation of clothing, unable to clean the cloth, easy to adhere to the workbench, etc., to achieve convenient The effect of cleaning work, reducing secondary pollution, and moving stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

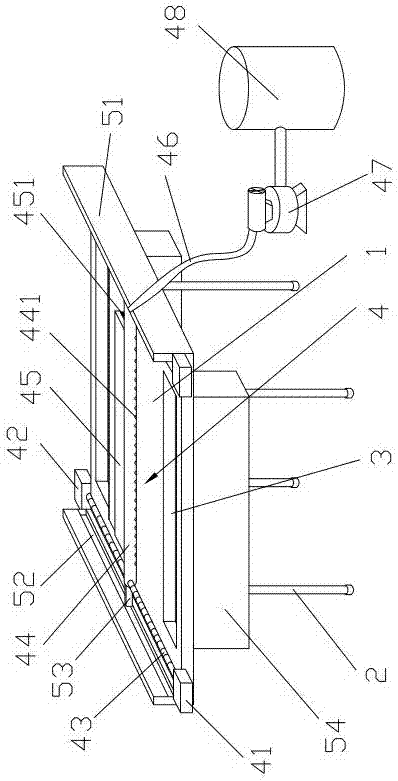

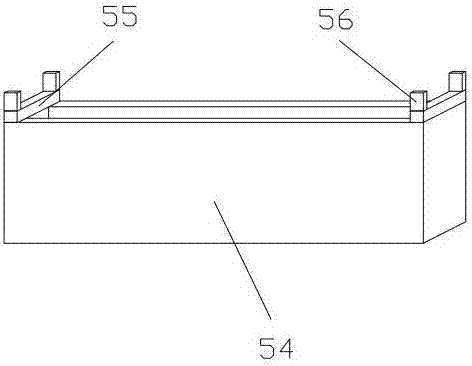

[0017] Such as Figure 1-2 As shown, it is a fabric cutting table with a cleaning device according to the present invention, which includes a workbench 1 and a support frame 2. The front and rear sides of the workbench 1 are provided with chip troughs 3, and directly below the swarf drop 3 is provided with a second Two collection boxes 54, the area of the case opening of the second collection box 54 matches the area of the chip drop groove 3. The second collection box 54 provided is used to collect the waste chips swept from the chip drop chute 3, so as to prevent the waste chips from falling directly on the ground, pollute the workshop, reduce secondary pollution and clean. The left and right sides of the second collection box 54 top surface are all provided with limit block 55, and limit block 55 is provided with elastic block 56, and the bottom surface of workbench 1 is provided with limit groove, is provided with installation bayonet on the limit groove, The limiting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com