Stone agglomerate slab or flagstone with tio2 or zno coating

A technology of coalescence and mixture, applied in coating, metal material coating process, ion implantation plating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

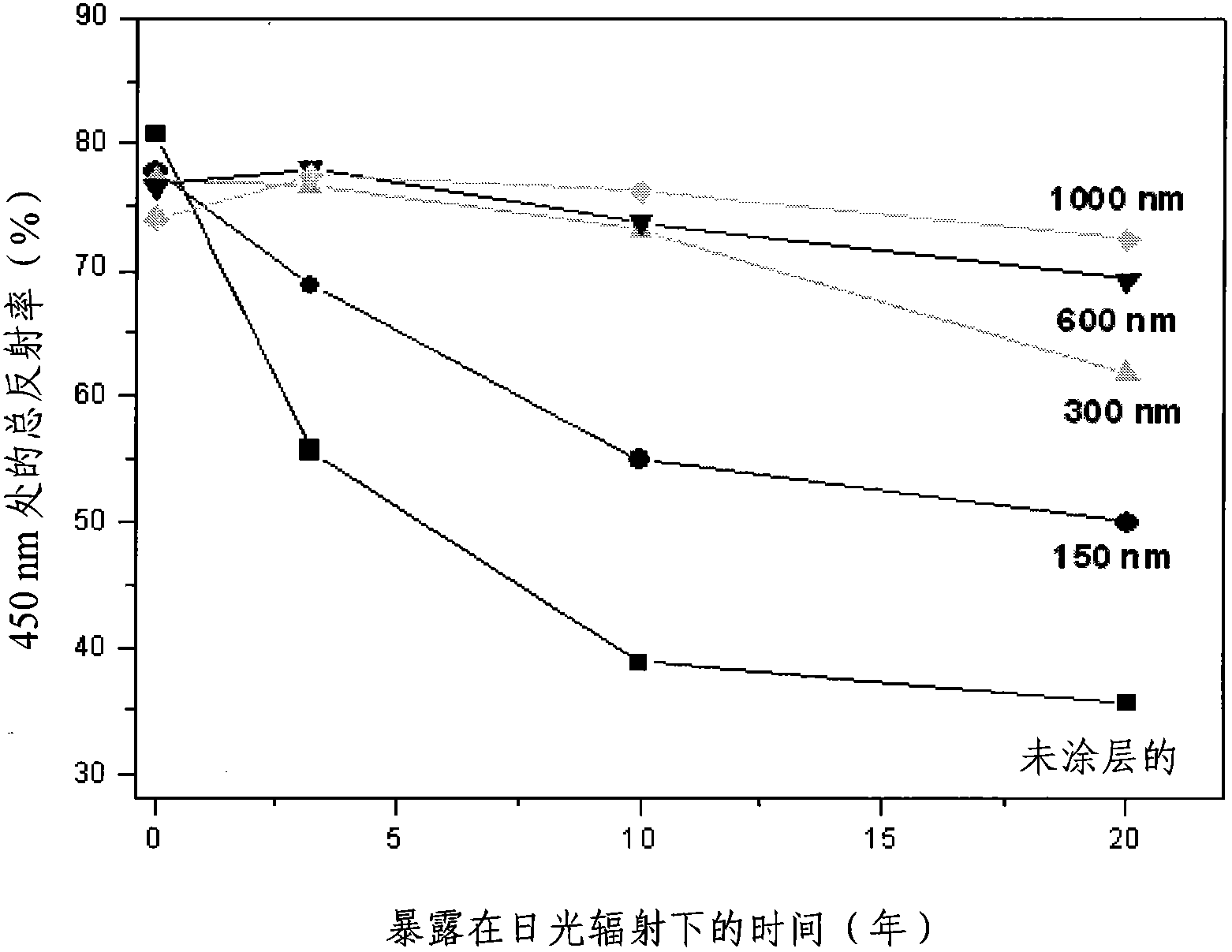

[0058] Example 1: TiO with amorphous structure and different thicknesses using PECVD technique under vacuum 2 Thin films Coated quartz agglomerate plates with dimensions 300 x 150 cm and a thickness of 20 mm.

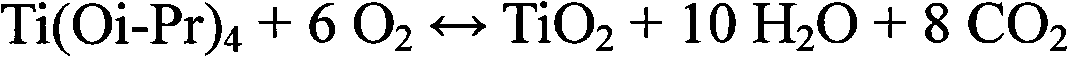

[0059] Using PECVD technology under vacuum, according to the required thickness, under the following conditions, by changing the deposition time, the TiO 2 Transparent thin films deposited on quartz agglomerate surfaces:

[0060] -Oxidizing gas (pure O) with a flow rate of 240mL / min 2 ) generated plasma.

[0061] - Time to activate the surface of the quartz agglomerate with plasma: 5 min.

[0062] - Power to form plasma: 400W, frequency 2.45GHz.

[0063] - Working pressure: 3 millitorr (mtorr).

[0064] - Volatile precursor: Titanium(IV) tetraisopropoxide impregnated in a thermostatic storage chamber at 40°C.

[0065] - O entraining vapors of volatile precursors into the plasma 2 Derivative flow rate: 2.5mL / min.

[0066] - Deposition rate: 0.9 μm / h.

[0067] ...

Embodiment 2

[0081] Example 2: Quartz agglomerate plates with dimensions of 300 × 150 × 2 cm were coated with an amorphous structure and a transparent film of ZnO with a thickness of 500 nm using the PECVD technique.

[0082] Deposition was carried out under the following conditions:

[0083] -Oxidizing gas (pure O) with a flow rate of 15mL / min 2 ) generated plasma.

[0084] - Time to activate the surface of the quartz agglomerate with plasma: 5 min.

[0085] - Formation of O 2 Plasma power: 200W, frequency 2.45GHz.

[0086] - Working pressure: 1Pa.

[0087] - Volatile precursor: Diethylzinc (Zn(Et) 2 ).

[0088] - Flow rate of volatile precursors: 5 mL / min.

[0089] - Deposition rate: 1.0 μm / h.

[0090] - Deposition temperature: 25°C.

[0091] The resulting board was evaluated in a similar manner to Example 1. In this case, the resulting sample improved by a factor of 25 in resistance to solar radiation. The resulting surface is also superhydrophilic in sunlight, so it can be...

Embodiment 3

[0095] Example 3: TiO with amorphous structure and different thicknesses using reactive sputtering PVD technique 2 A transparent film coats a quartz agglomerate plate with dimensions 300 x 150 x 2 cm.

[0096] Deposition was carried out under the following conditions:

[0097] - Target used: metallic Ti.

[0098] - Applying a potential difference of 531V and 6.57kW / cm 2 The power of 0.58kHz is used to accelerate the bombardment of the target by Ar ions to vaporize it.

[0099] - Working pressure: 7×10 -3 support.

[0100] - Oxidizing gas (O 2 ) flow rate: 1.3mL / min.

[0101] - Deposition rate: 1.0 μm / h.

[0102] - Deposition temperature: 70°C.

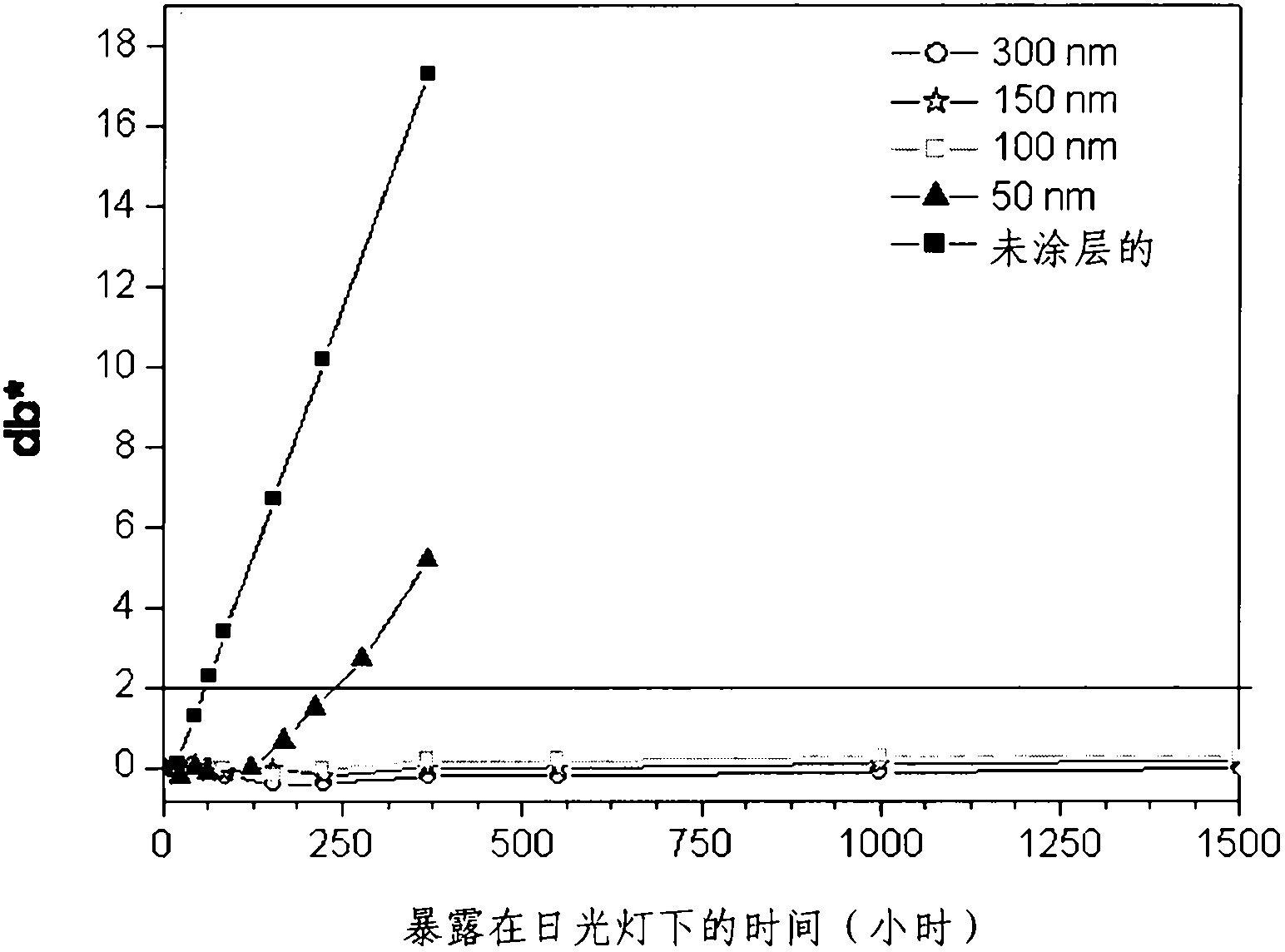

[0103] The resulting panels were evaluated for resistance to solar radiation in a manner similar to Example 1, in this case by the color parameter b * change (yellow) ( figure 2 ), it can be seen that the degradation of the surface of the quartz agglomerate target, when db * With an increase of 2 units, it was possible to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com