Automatic stone unloader

An automatic stone unloading technology, applied in the direction of stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of difficult maintenance, high installation accuracy, and little room for speed improvement, and achieve small footprint and high efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

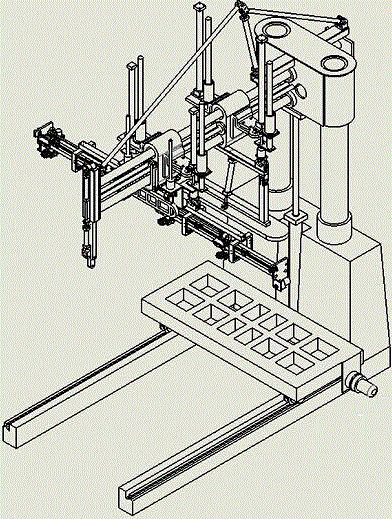

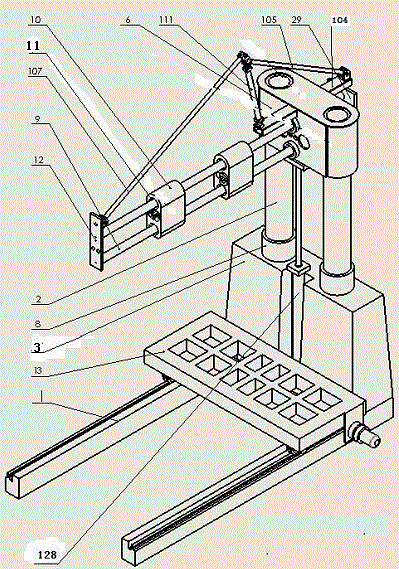

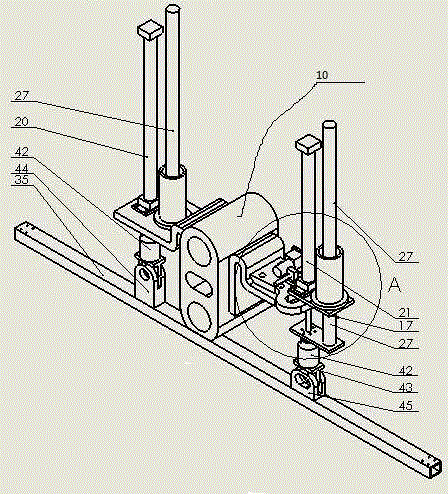

[0032]The frame in this device consists of a chassis that can be extended into the fork of a forklift. Two chrome-plated columns are fixed and welded to the chassis. The liftable beam is fixed on the flat seat of the column sliding sleeve and connected with the hydraulic cylinder to realize lifting. The movement of the column; the column sliding sleeve is composed of the inner copper sleeve and the outer fixed sleeve; the column sleeve is connected with the bottom plate of the beam seat and the beam.

[0033] The liftable crossbeam consists of two chrome-plated optical shafts installed in the horizontal direction, an automatically adjustable triangular cable stay composed of two pull irons and hydraulic cylinders, a front end plate and a rear end plate, two movable with adjustable copper The cutting machine frame and the manipulator seat of the sliding sleeve are respectively driven by the motor to reduce the speed reducer and the screw mandrel.

[0034] Automatic cali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com