Composite replacing and filling structure and treatment method for valley-type soft soil

A composite, soft soil technology, used in roads, buildings, roads, etc., can solve the problems of large amount of soft foundation replacement, huge costs, and shortage of material sources, so as to shorten the construction time, shorten the construction time, and reduce the production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

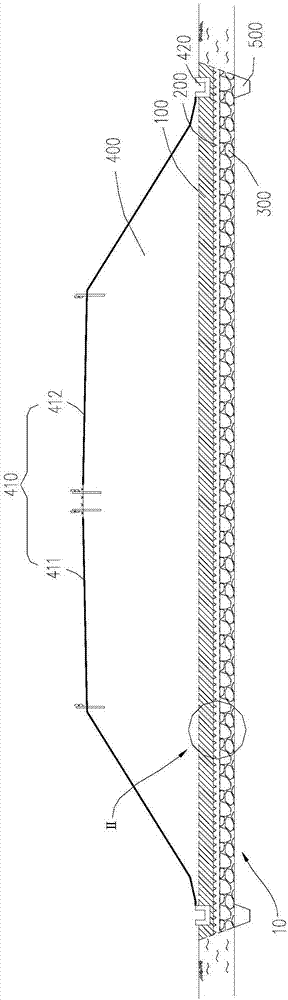

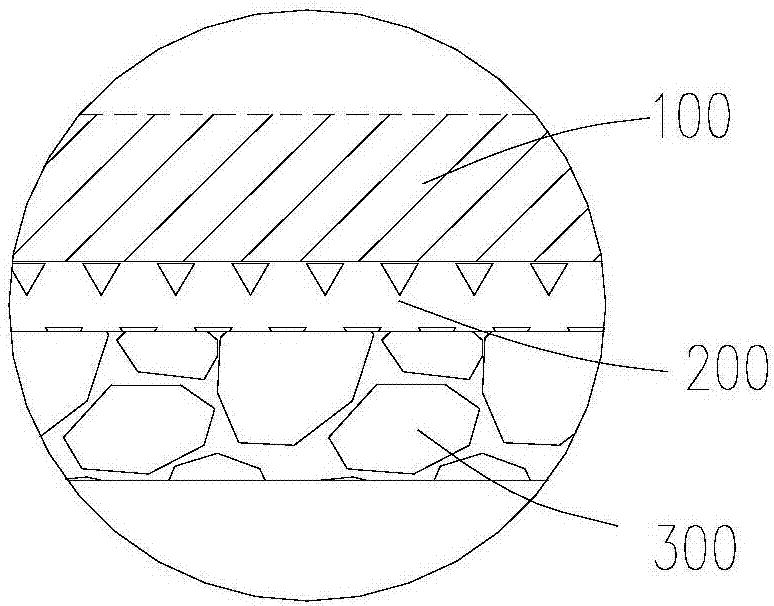

[0035] see figure 1 , the present embodiment provides a composite replacement structure 10 of soft soil of valley phase, which is applied to the treatment of soft soil foundation of valley phase in granite areas, which can save engineering investment, shorten construction time, and effectively ensure the treatment effect of soft ground. Among them, the valley-facies soft soil composite replacement structure 10 includes a granite residual soil layer 100, a crushed stone layer 200 and a chipping stone layer 300. superior.

[0036] Please refer to figure 1 and figure 2 , in this embodiment, the granite residual soil layer 100, the crushed stone layer 200 and the flake layer 300 are laid below the ground level. The compaction degree of each layer is required to meet the requirements of 90% to 93%, so as to avoid excessive settlement or foundation instability due to insufficient compaction of the granite residual soil layer 100, crushed stone layer 200 and flake layer 300, maki...

no. 2 example

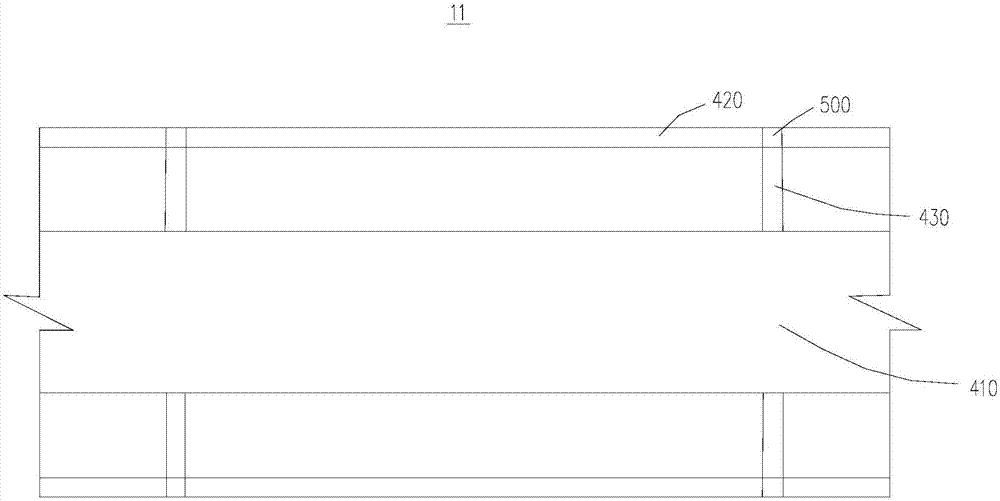

[0046] Please refer to figure 1 and image 3 , this embodiment provides a granite valley-facies soft soil subgrade 11, which uses the valley-facies soft soil composite replacement structure 10 provided in the first embodiment, which can save engineering investment, shorten construction time, and effectively ensure soft soil. base treatment effect. Among them, the soft soil roadbed 11 of granite valley phase includes a highway roadbed 400 and a composite replacement structure 10 of valley phase soft soil.

[0047] The highway subgrade 400 is set on the granite residual soil layer 100, and the cross section of the highway subgrade 400 is roughly trapezoidal. for the vehicle to drive. In this embodiment, roadbed side ditches 420 are respectively opened on both sides of the roadbed 400. The roadbed side ditch 420 is consistent with the extension direction of the roadbed 400. Avoid too much accumulated water from affecting the stability of the roadbed 400 . In addition, a plur...

no. 3 example

[0051] see Figure 4 , this embodiment provides a treatment method, which is applied to the valley phase soft soil composite replacement structure 10 provided in the first embodiment, which can shorten the construction time, reduce production costs, and ensure that the soft foundation treatment effect can achieve a better good standard. Among them, the treatment method includes the following steps:

[0052] Step S101, construction preparation;

[0053] Wherein, the preparation step includes: preparing the rubble required for laying the rubble layer 300, and the uniaxial saturated compressive strength of the rubble is greater than or equal to 30MPa; preparing the crushed stone required for laying the crushed stone layer 200, and the mud content of the crushed stone is less than 5%, dry density greater than 2.0t / m 3 Prepare the granite residual soil required for laying the granite residual soil layer 100, and the liquid limit of the granite residual soil is less than 50%, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com