Positioning clamp for machining flagstone surface and method for grinding flagstone surface

A positioning fixture and surface processing technology, which is applied in positioning devices, manufacturing tools, metal processing equipment, etc., can solve the problems that human hands cannot be positioned, and the consistency of flatness and edges cannot be guaranteed, and achieves good flatness. , beautiful appearance, high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

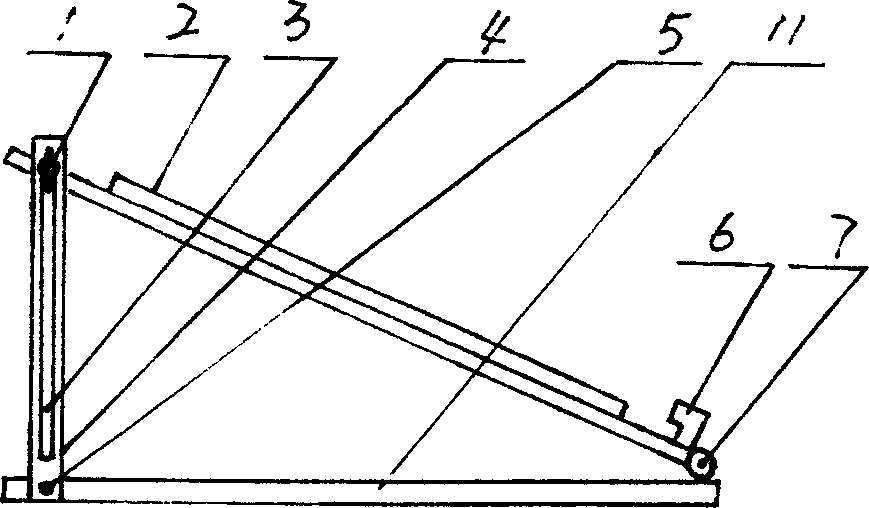

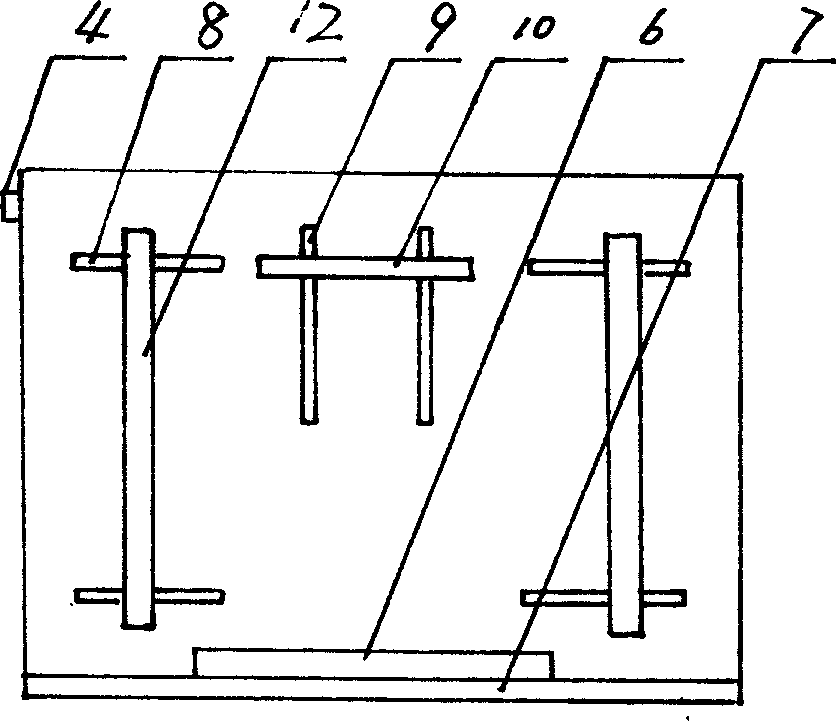

[0010] Embodiment 1: with reference to attached figure 1 with 2 . Slate surface processing positioning fixture, the rectangular frame or rectangular board 11 is processed into a rectangular frame or rectangular board by using wood or plastic or resin board or bakelite board according to the prior art, the rectangular frame or rectangular board and the splint 2 are hinged by the shaft 7 and can be up and down move. One side or both sides of rectangular frame or rectangular plate 11 and clamping plate 2 are provided with clamping plate angle adjustment lever 4 and are used for adjusting and positioning clamping plate 2 and the angle between rectangular frame or rectangular plate 11, when clamping plate 2 and rectangular frame or rectangular plate 11 After the included angle is adjusted, tighten the positioning nut 1 to position the splint angle adjustment rod 4 with the rectangular frame or rectangular plate. Clamping plate 2 has horizontal splint strip active groove or hole ...

Embodiment 2

[0011] Embodiment 2: On the basis of Embodiment 1, the method of positioning and grinding the slate surface is adopted with the slate surface processing positioning fixture. The slate surface processing positioning fixture is located on the working table of the drilling, milling, boring and grinding machine, and the plate to be ground is located on the splint , the plate is clamped or clamped or clamped and clamped firmly, adjust the angle adjustment lever of the splint to make the surface of the plate to be ground on the splint at the required angle, set the grinding amount of the drilling, milling and boring grinder, When the drilling, milling and boring grinder is started, the grinding head will automatically move down to touch the slate and grind left and right until the set grinding amount is reached, or the grinding head will automatically move down to touch the slate, and the working table of the drilling, milling and boring grinder will move left and right, forcing the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com