Laying system for floor tiles

A technology for flooring and slate, which is applied to paving, floors, roads and other directions paved with prefabricated blocks. cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

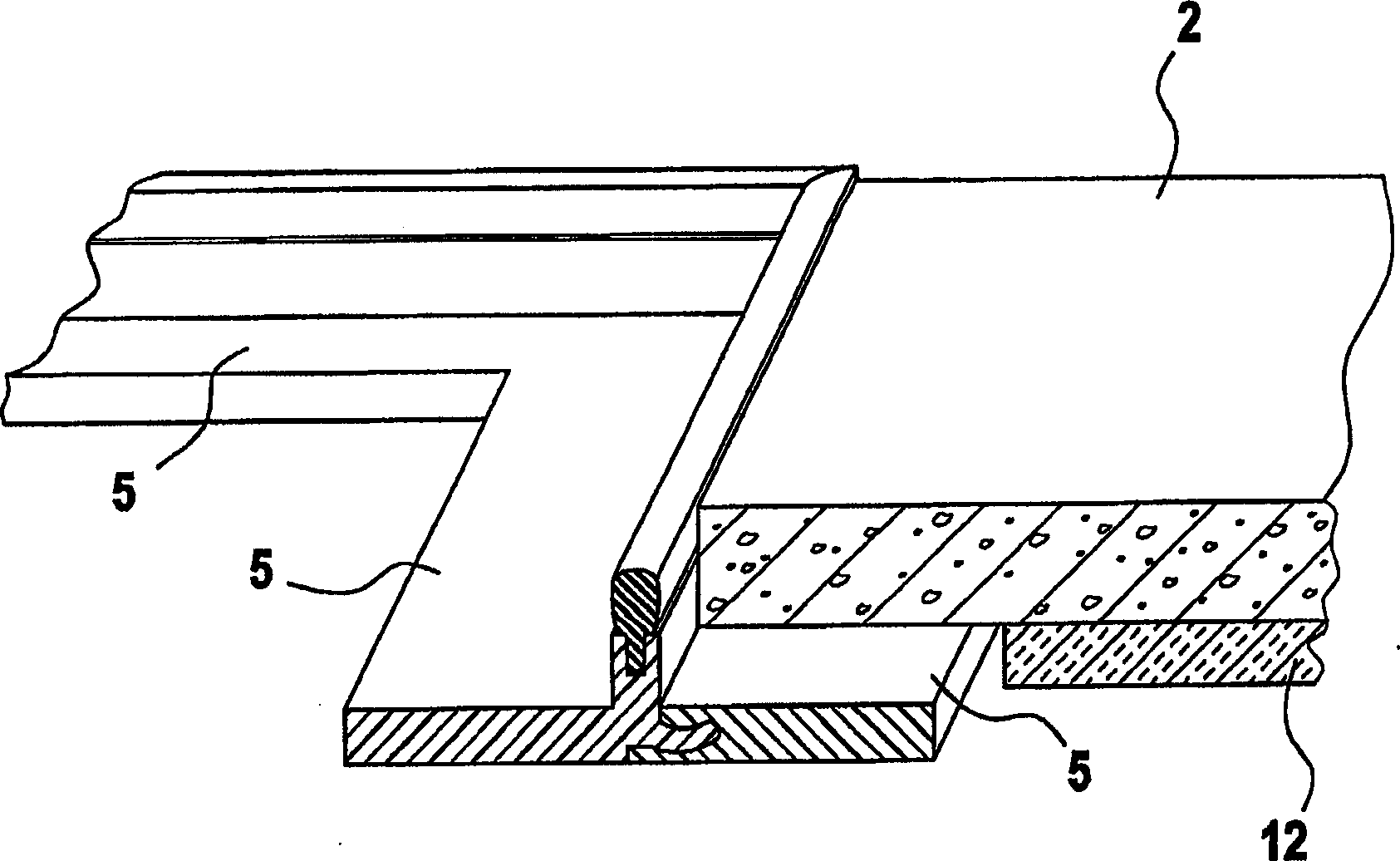

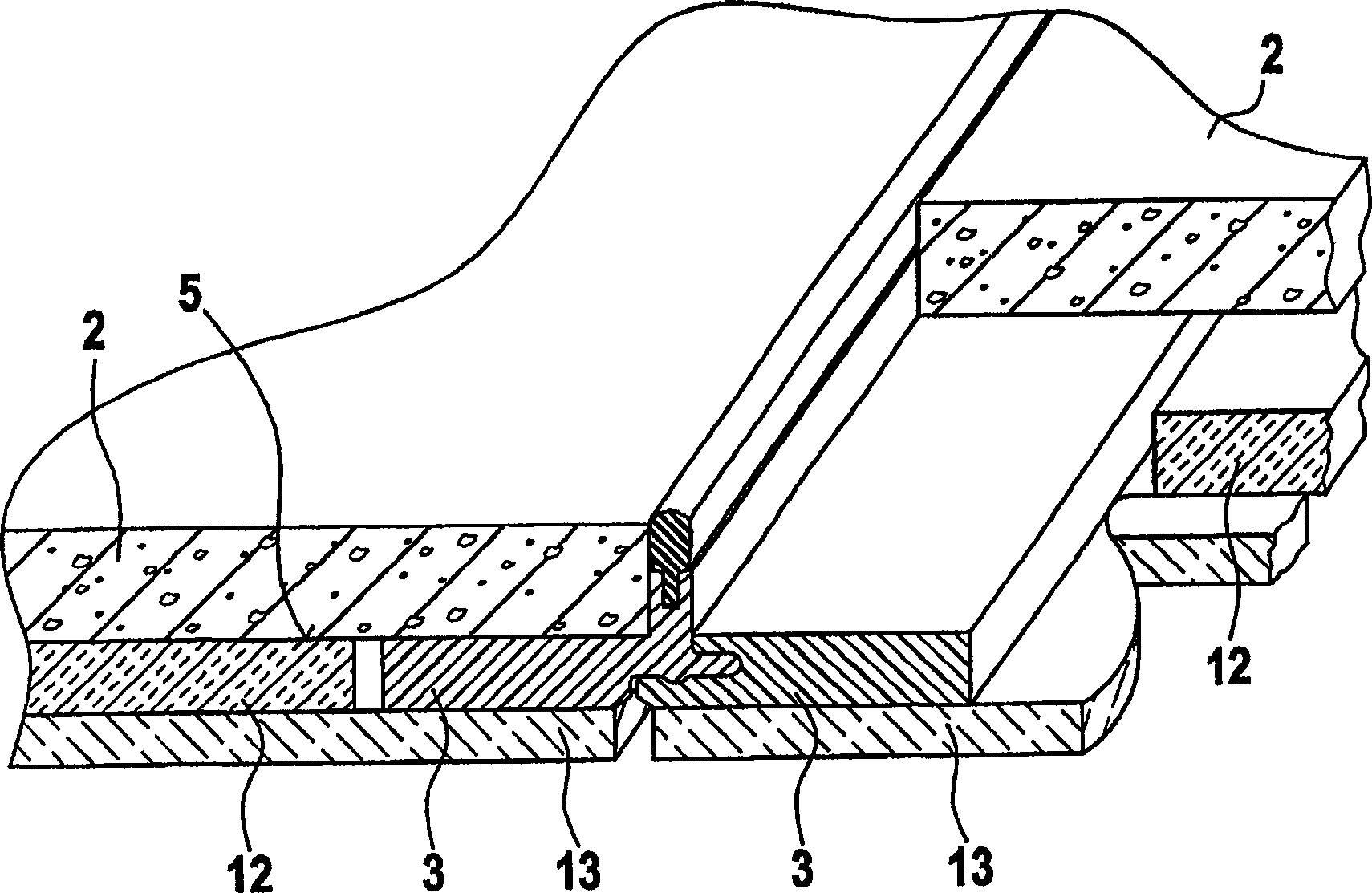

[0032] The illustrated embodiments are all based on a floor covering, which is composed of a number of rows of stone slabs, such as granite slabs, which are laid floating on a foundation, such as a rough cement floor or a wooden floor, with a spaced joint in the middle. on the floor.

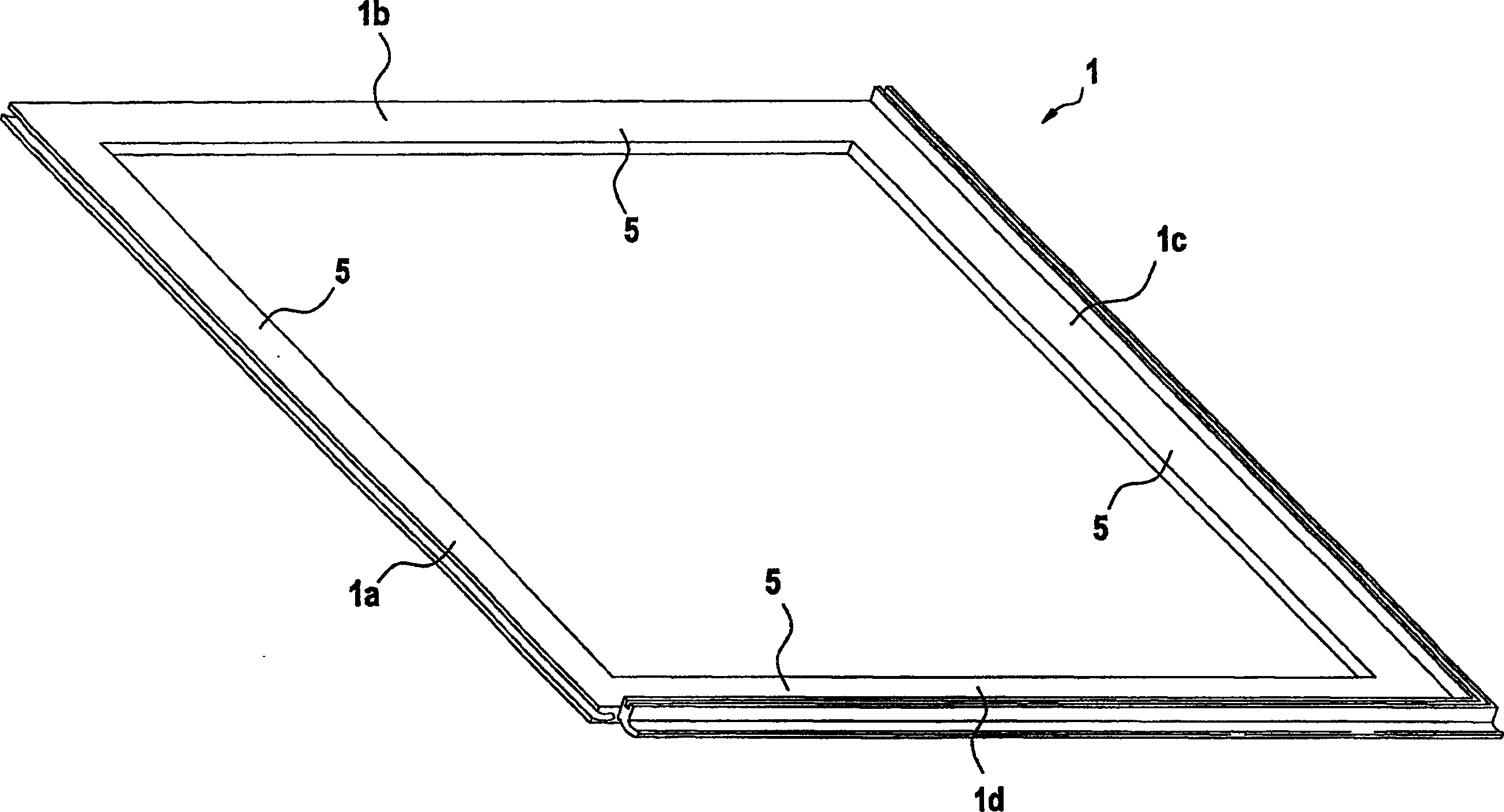

[0033] figure 1 In one view, a quadrilateral frame 1 for supporting a slab (not shown in the figure) such as a granite slab is shown. The frame 1 is made of plastic and is prefabricated. It can be an integral injection-molded part or some parts, which are composed of an extruded profile. Recycled plastics can also be used as raw materials.

[0034] Among the four frame edges 1a-1d of the frame 1, the two adjacent frame edges 1c and 1d have one such as Figure 4 The cross-sectional view of the special-shaped plug-in part 3 is shown. The other two frame edges 1a and 1b have one such as Figure 5 The cross-sectional view shows the special-shaped plug-in part 4. The four frame edges 1a-1d have a strip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com