Laying system for floor tiles

A technology for supporting frames and floors, which is applied to paving, buildings, and building structures paved with prefabricated blocks. It can solve problems such as labor-intensive workers, high manual skills, and floor paving that cannot be disassembled smoothly, so as to reduce the cost of paving. , to avoid the effect of planking errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

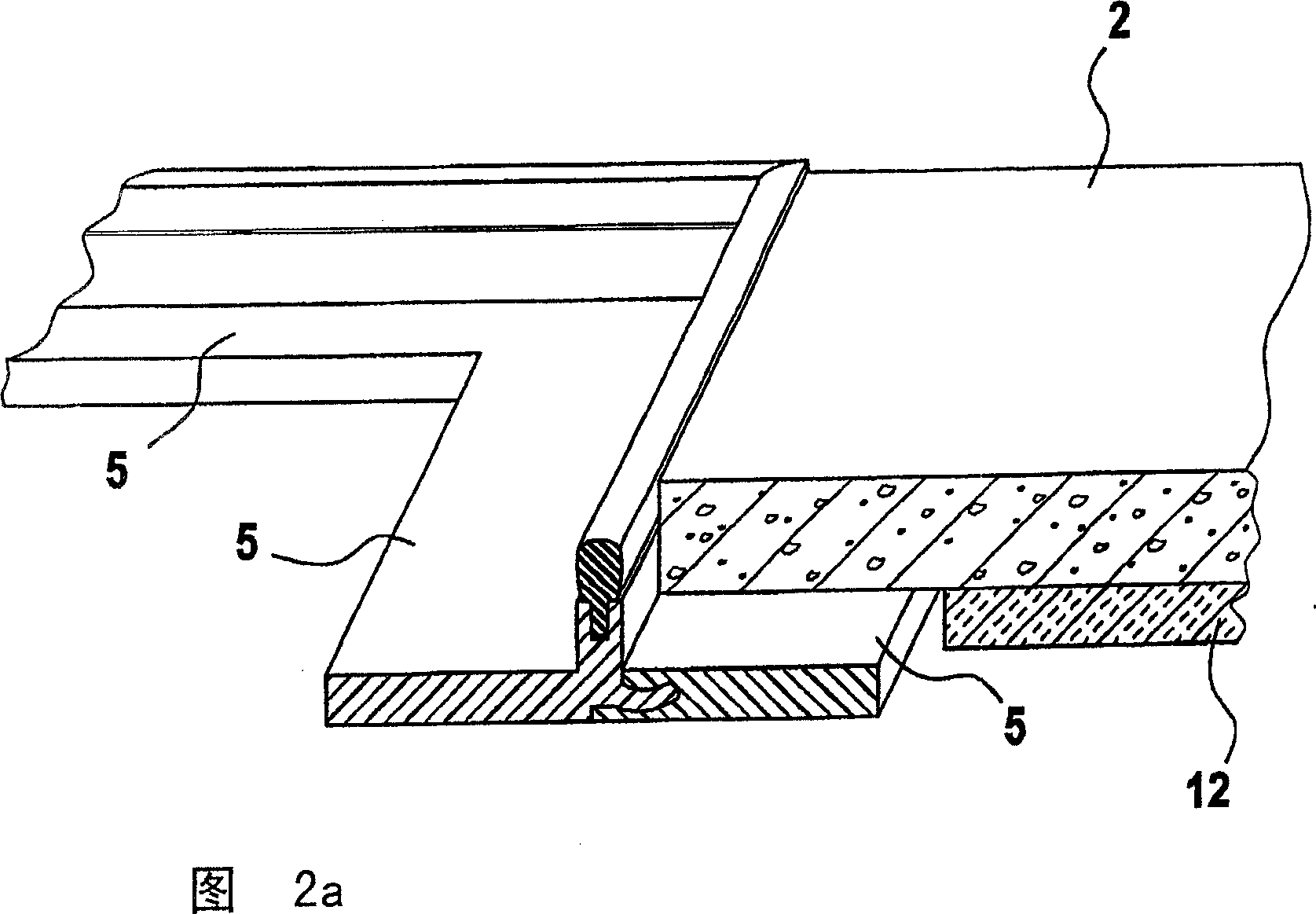

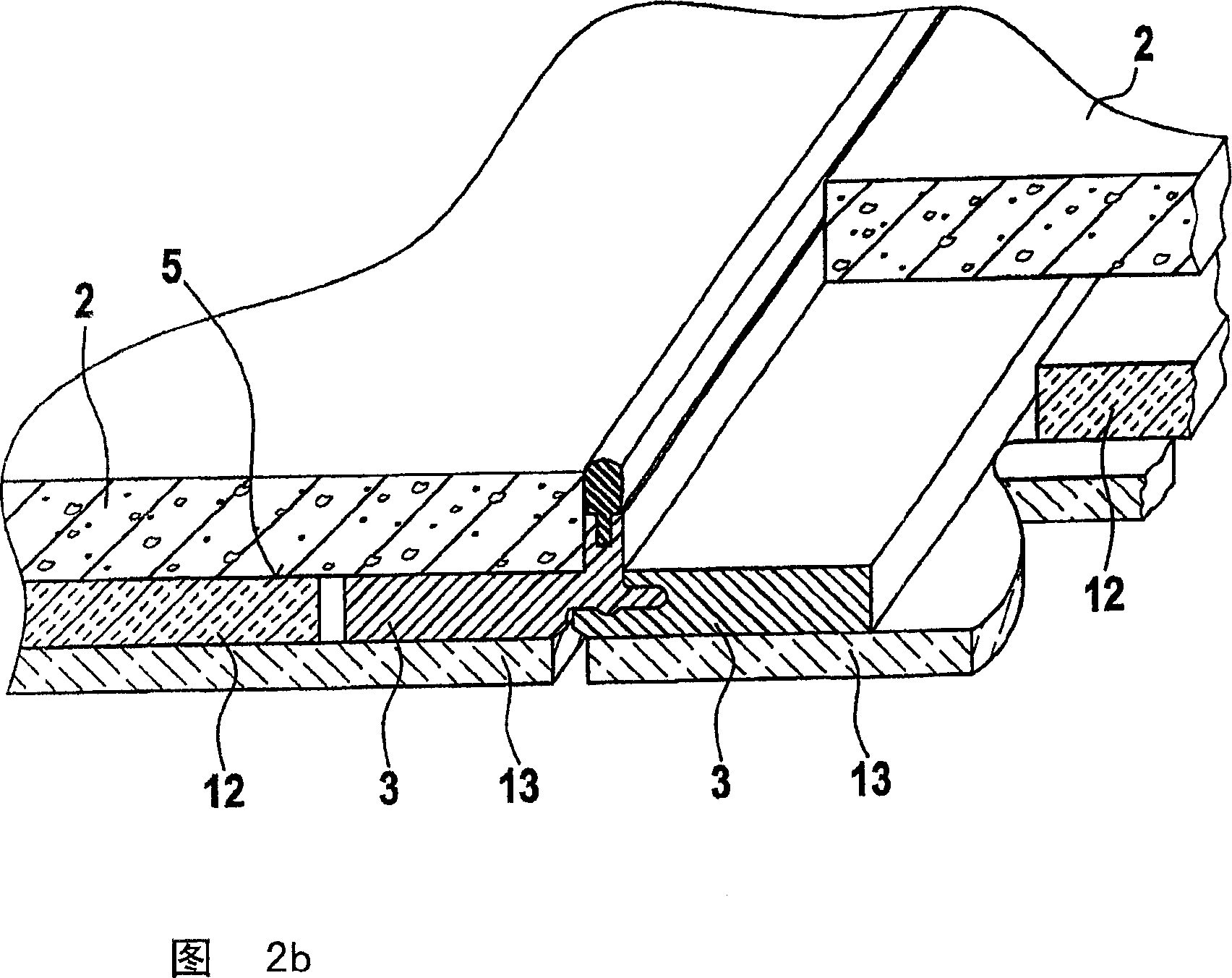

[0035] The illustrated embodiments are all based on a floor covering consisting of a number of row-by-row slabs, such as granite slabs, which are laid floating with a spaced joint in between, on a foundation, such as a rough-concrete floor or a wooden floor. on the floor.

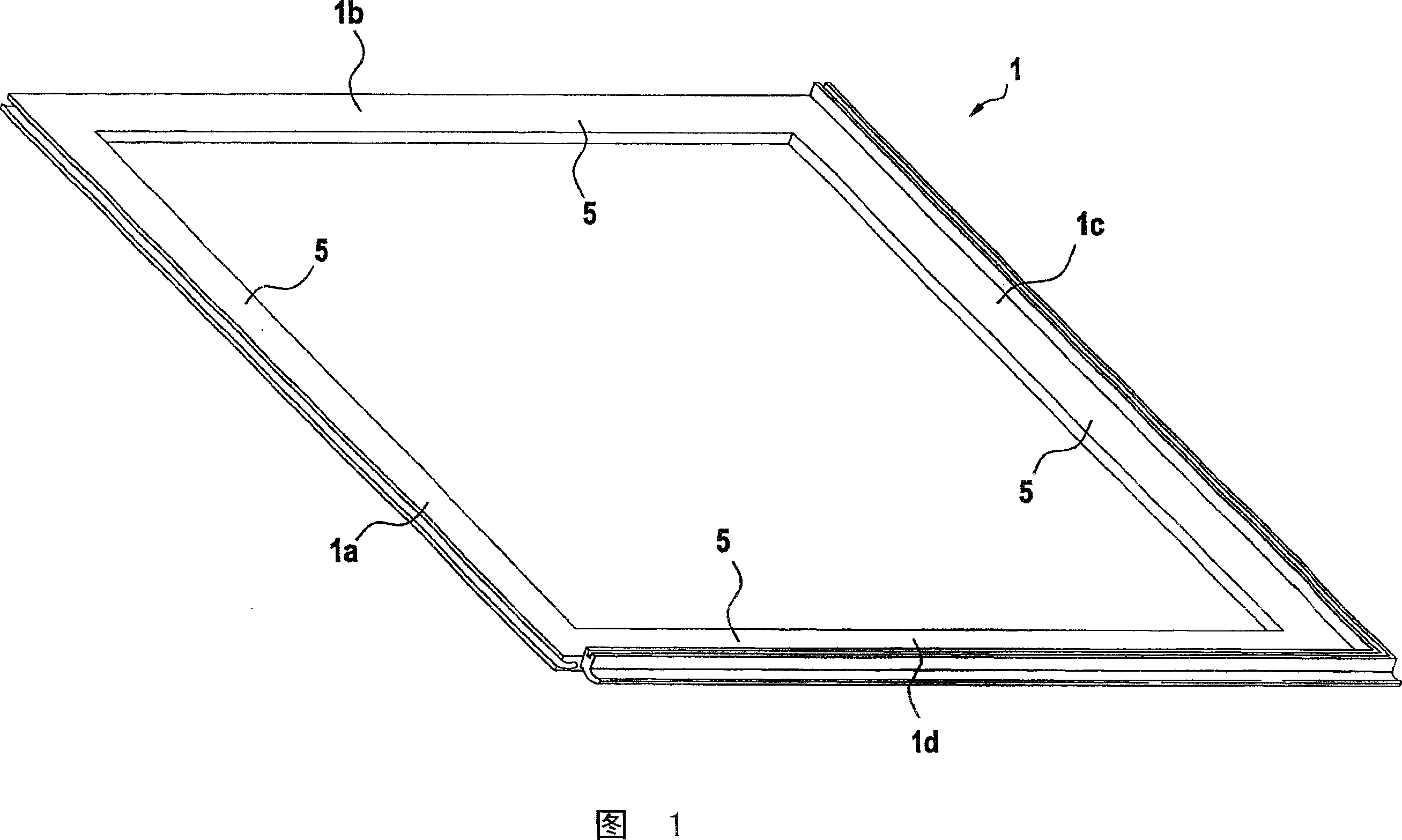

[0036] Figure 1 shows in one view a quadrilateral frame 1 for supporting a slab (not shown in this figure), such as a granite slab. The frame 1 is made of plastic and is prefabricated, it can consist of a single injection molded part or of parts which consist of an extruded profile. Recycled plastic can also be used as raw material.

[0037] Among the four frame sides 1a-1d of the frame 1, two frame sides 1c, 1d adjacent to each other have a special-shaped insertion part 3 as shown in the cross-sectional view of FIG. 4 . The other two frame sides 1a, 1b have a special-shaped insertion part 4 as shown in the cross-sectional view of FIG. 5 . The four frame sides 1 a - 1 d have a strip-shaped support surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com