Method for preparing artificial stone from iron-containing slag obtained in pyrometallurgucal process

A technology of pyrometallurgy and artificial stone, which is applied in the field of energy-saving, environmental protection and high-efficiency utilization of iron-containing slag obtained by pyrometallurgy, to achieve the effects of simple operation, improved fluidity, and favorable crystallization and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

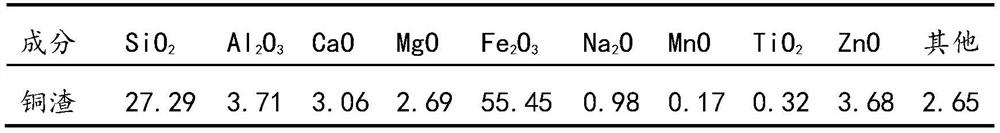

[0054] The chemical composition of copper slag involved in Example 1 of the present invention is described as follows. Table 1 shows the chemical composition of copper slag in Example 1 of the present invention and its weight percentage.

[0055] Table 1 Chemical composition of copper slag / wt.%

[0056]

[0057] Adding 3.5wt.% Na at the same time in the molten copper slag discharge process 2 CO 3 ; After slagging, the modified slag was kept at 1300°C for 30 minutes, and then cast into a mold preheated to 900°C for casting; after that, the molded parts were placed in a crystallization furnace, and held at 900°C for 2 hours for crystallization treatment; finally , cooling down to 650°C and then holding for 2 hours for annealing, to obtain a glass-ceramic with magnetite as the main crystal phase and diopside as the secondary crystal phase.

[0058] Mass percentage of key chemical components of glass-ceramics: Na 2 O is about 2wt.%; Fe 3 o 4 About 55wt.%, artificial stone ...

Embodiment 2

[0060] Add 3.0wt.% NaOH to the bottom of the copper smelting slag tank in Example 1 in advance, fully mix and modify the slag after slag discharge, keep the modified slag at 1300 ° C for 30 minutes, and cast it in a preheated to Casting in a mold at 650°C, and putting the molded piece into a heat treatment furnace and holding it at 900°C for 1 hour for crystallization treatment; finally, cooling to 650°C and holding it for 1 hour for annealing treatment to obtain the microcrystalline magnetite as the main crystal phase. crystal glass.

[0061] Mass percentage of key chemical components of glass-ceramics: Na 2 O is about 2wt.%; Fe 3 o 4 About 55wt.%; the compressive strength of artificial stone can reach 356.55MPa, and the flexural strength can reach 55.18MPa.

Embodiment 3

[0063] The copper smelting slag in Example 1 is directly blown and oxidized with air, then kept at 1280°C for 30 minutes, cast in a mold preheated to 1100°C, and put into a heat treatment furnace to keep it warm at 1100°C Crystallization treatment was carried out for 1 hour; finally, the temperature was lowered to 650° C. and then kept for 1 hour for annealing treatment to obtain glass-ceramic with magnetite as the main crystal phase.

[0064] Mass percentage of key chemical components of glass-ceramics: Na 2 O is about 0.98wt.%; Fe 3 o 4 About 55wt.%; the compressive strength of artificial stone can reach 356.55MPa, and the flexural strength can reach 51.18MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com