Method for producing zirconia-alumina composite ceramic material, zirconia-alumina composite granulated powder, and zirconia beads

A composite ceramic and manufacturing method technology, applied in the fields of nanotechnology, thin material processing, nanotechnology, etc. for material and surface science, can solve problems such as particle size control, achieve suppression of particle overflow, excellent wear resistance and The effect of hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

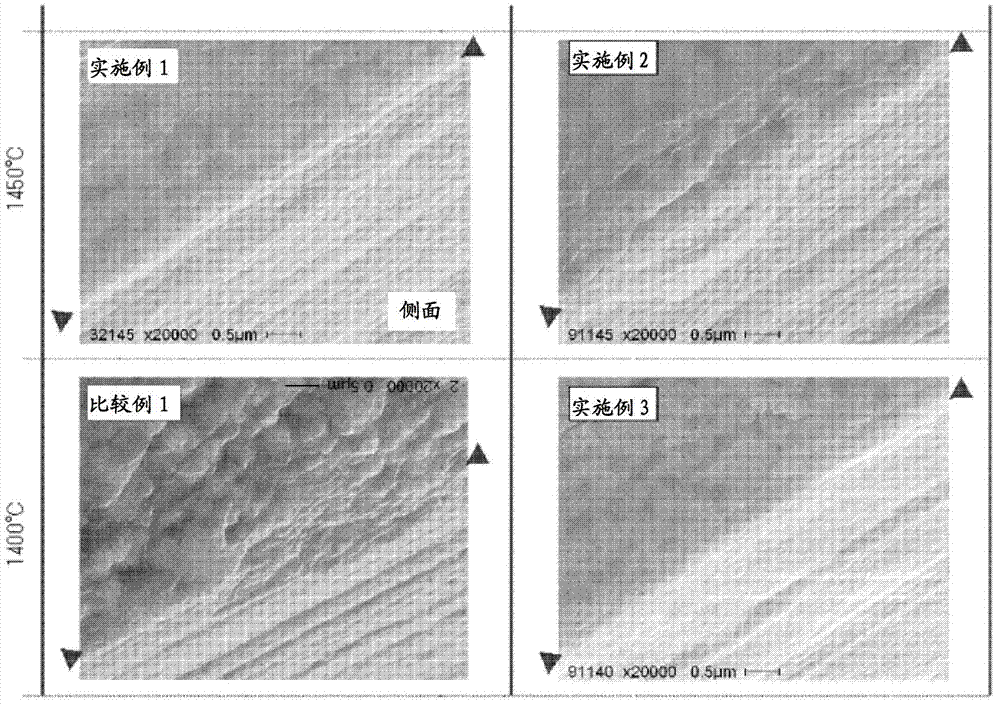

Embodiment 1~5 and comparative example 1~4)

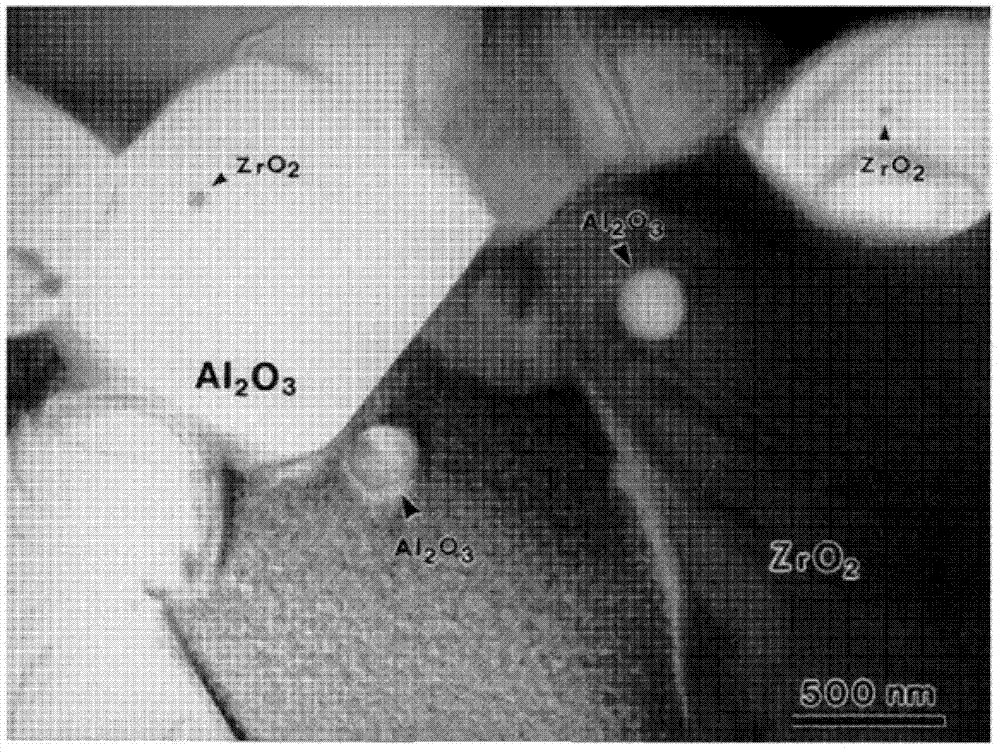

[0084] As the first powder for providing the first phase formed of zirconia particles, a stabilizer containing 12 mol % of ceria and 0.04 mol % of titanium dioxide and having a specific surface area of 15 m 2 g -1 of tetragonal zirconia powder.

[0085] As the second powder for providing the second phase formed of alumina particles, a powder with a specific surface area of 55 m was used which was produced by the gas phase method (laser ablation method). 2 g -1 And a mixture of spherical γ-alumina powder with an average particle size of 0.03 μm and α-alumina powder with an average particle size of 0.1 μm.

[0086] The first powder and the second powder were mixed, 100 parts by volume of water was added to 100 parts by volume of the mixture to prepare a slurry, and the first powder and the second powder were mixed and pulverized in the slurry. The particle size distribution of the first powder and the second powder in the obtained slurry was measured using SALD2000 (laser...

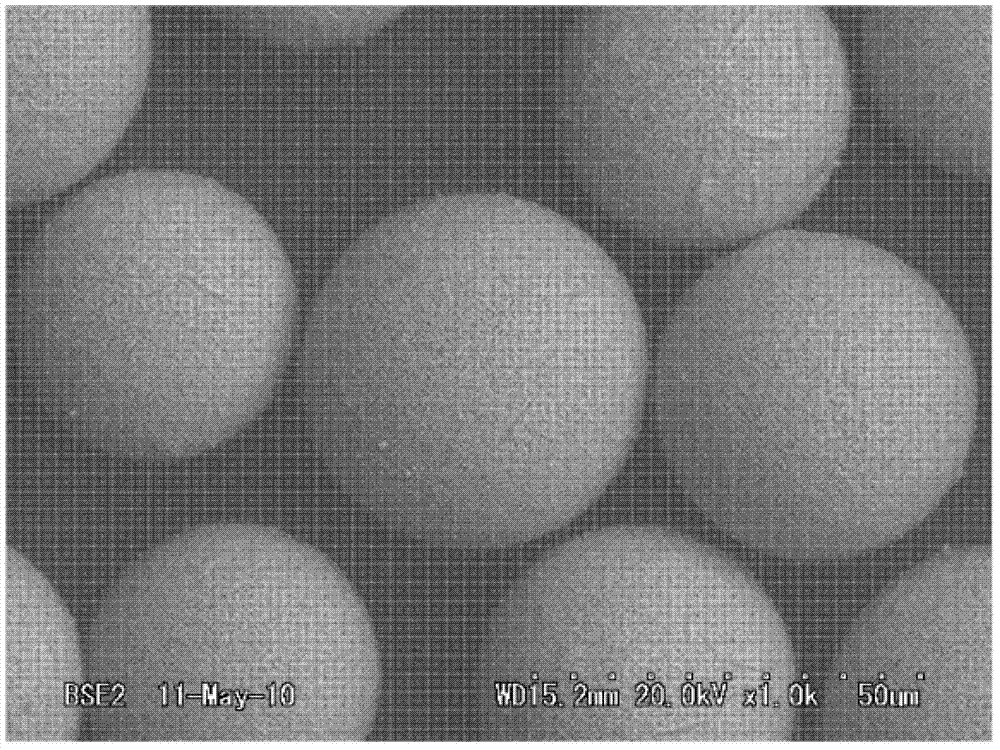

Embodiment 6)

[0096] As the first powder for providing the first phase formed of zirconia particles, a stabilizer containing 12 mol % of ceria and 0.04 mol % of titanium dioxide and having a specific surface area of 15 m 2 g -1 of tetragonal zirconia powder. The content of the tetragonal zirconia powder is 100% by volume, and the average particle diameter is within the range of 0.3 to 0.5 μm.

[0097] As the second powder for providing the second phase formed of alumina particles, a powder with a specific surface area of 55 m was used which was produced by the gas phase method (laser ablation method). 2 g -1 And a mixture of spherical γ-alumina powder with an average particle size of 0.03 μm and α-alumina powder with an average particle size of 0.1 μm. In the second powder, the mass ratio of α-alumina powder:γ-alumina powder was 70:30. That is, the compounding quantity of the γ-alumina powder was 42.9 mass % with respect to the α-alumina powder. The average particle size of the sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com