Preparation method of antireflection film applicable to different bases

A technology of anti-reflection film and substrate, which is applied in the direction of solid-state chemical plating, metal material coating process, coating, etc., can solve the problems of increasing the difficulty and cost of anti-reflection film preparation, achieve low raw material cost, easy implementation, Ease of scale-up production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

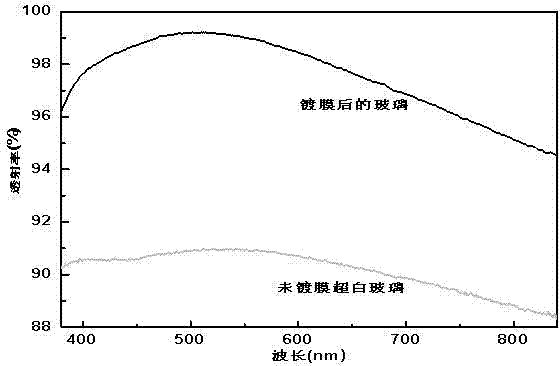

[0021] Preparation of anti-reflection coating on the surface of ordinary ultra-clear glass

[0022] Tetraethyl orthosilicate (TEOS), ammonia (NH 3 ·H 2 O) and absolute ethanol (EtOH) in a molar ratio of 1:3:50 were mixed and stirred evenly, and placed in a stable environment (20°C, 30% relative humidity) for aging for 7 to 10 days. During the preparation process, in order to control the hydrolysis reaction rate, the ammonia water was dissolved in an appropriate amount of ethanol and then slowly added dropwise to the mixture of TEOS and ethanol. After the sol is aged to light blue latex, reflux at 80 °C until the catalyst ammonia in the sol is removed, and the desired granular silica sol can be obtained.

[0023] Tetraethyl orthosilicate (TEOS), deionized water (H 2 O), hydrochloric acid (HCl) and absolute ethanol (EtOH) according to the molar ratio of 1: 2: 0.2: 40, mixed and stirred evenly, placed in a stable environment (20 ° C, relative humidity 30%) for 7 days to obtain...

Embodiment 2

[0028] Preparation of anti-reflection coating on gallium arsenide substrate surface

[0029] Butyl titanate (Ti(OC 4 h 9 ) 4 , TBOT), absolute ethanol (EtOH), deionized water (H 2 O), glacial acetic acid (HAc), and acetylacetone (AcAc) in a molar ratio of 1:8:3:1.5:0.2 were fully stirred for 2 hours in an environment with a temperature of about 20 °C and a relative humidity of less than 60%, and then aged for 5 - Obtain transparent titanium oxide sol in 7 days. During the preparation process, first dissolve TBOT in half of EtOH, add HAc dropwise while stirring, and the obtained solution is called A solution; then H 2 O is mixed with the other half of EtOH, and the resulting solution is called B solution; finally, B solution is slowly added dropwise to A solution and stirred evenly.

[0030]The preparation process of the three-dimensional chain network structure silica sol is as described in Example 1.

[0031] Slowly add the silica sol with a three-dimensional chain netw...

Embodiment 3

[0034] Preparation of anti-reflection coating on zinc selenide crystal surface

[0035] Aluminum sec-butoxide (Al(C 4 h 9 O) 3 ), deionized water (H 2 O), nitric acid (HNO 3 ) and absolute ethanol (EtOH) according to the molar ratio of 1: 0.6: 0.1: 30, mixed and stirred evenly, placed in a stable environment (20 ° C, relative humidity 30%) and aged for 5 to 7 days to obtain alumina sol . During the preparation process, in order to control the hydrolysis reaction rate, the deionized water and nitric acid were dissolved in an appropriate amount of ethanol before being slowly added dropwise to the mixed solution of aluminum sec-butoxide and ethanol.

[0036] Butyl zirconate (Zr(OC 4 h 9 ) 4 , TBOZ), absolute ethanol (EtOH), deionized water (H 2 O), glacial acetic acid (HAc), and acetylacetone (AcAc) according to the molar ratio of 1:10:3:2:0.1 were fully stirred at room temperature for 2 hours, and then aged for 5-7 days to obtain a transparent zirconia sol. Pay attenti...

PUM

| Property | Measurement | Unit |

|---|---|---|

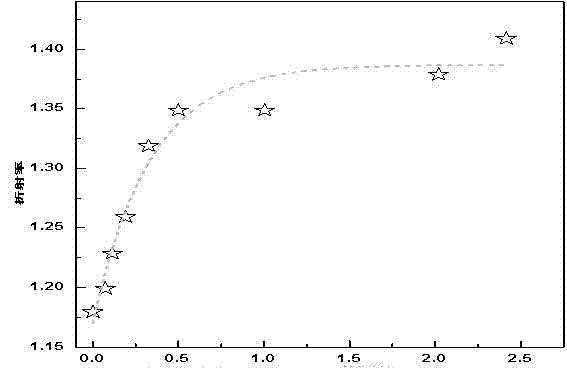

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com