Ultra-hard abrasive ceramic agglomerate and resin zirconia alumina composite grinding wheel

A super-hard abrasive and ceramic bond technology, applied in the direction of bonding grinding wheel, abrasive, grinding device, etc., can solve the problems of low rail material removal efficiency, fast grinding edge consumption, poor rail surface quality, etc. Wear resistance and removal efficiency, less grinding heat, good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

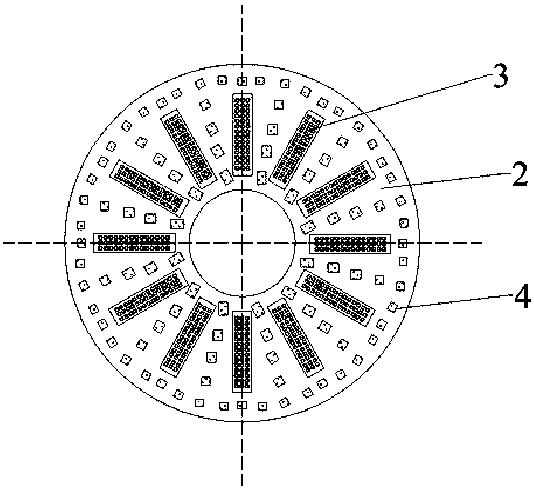

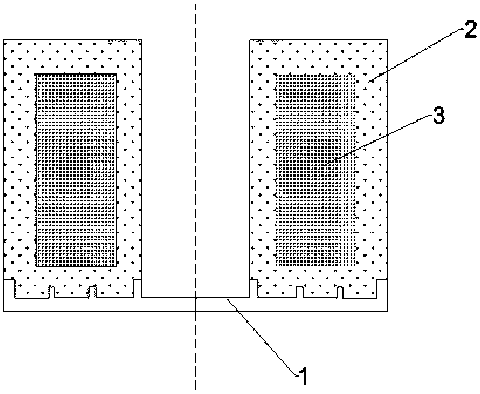

[0029] Composite grinding wheel for rail grinding, cuboid sintered blocks with a size of 55×20×10 mm, vitrified bond superabrasive sintered blocks 3, a total of 12 pieces, at an angular interval of 10°, distributed equiangularly over the entire circumference of the working layer of the grinding wheel, of which The rectangular surface of the sintered block with a size of 20 × 5 mm is the grinding surface. The diameter of the grinding wheel is 150 mm, the thickness is 60 mm, and the ring width of the grinding surface of the working layer is 50 mm. The composite grinding wheel is suitable for the turnout grinding train whose model is RGH20C.

[0030] The specific production steps are as follows:

[0031] (1) Weigh diamond, cubic boron nitride, ceramic bond and NaCl particles according to the mass ratio. The mass ratio of diamond and cubic boron nitride mixed abrasive is 60%, and the mass ratio of diamond to cubic boron nitride is 1:1 , the mass proportion of ceramic binder is 3...

Embodiment 2

[0038] Composite grinding wheel for rail grinding, cuboid sintered blocks with a size of 40×10×20 mm, vitrified bond superabrasive sintered blocks 3, a total of 12 pieces, at an angular interval of 15°, distributed equiangularly on the entire circumference of the working layer of the grinding wheel, of which The rectangular surface of the sintered block with a size of 20 × 5 mm is the grinding surface. The diameter of the grinding wheel is 150 mm, the thickness is 60 mm, and the ring width of the grinding surface of the working layer is 50 mm. The composite grinding wheel is suitable for the turnout grinding train whose model is RGH20C.

[0039] The specific production steps are as follows:

[0040] (1) Weigh diamond, cubic boron nitride, ceramic bond and NaCl particles according to the mass ratio. The mass ratio of diamond and cubic boron nitride mixed abrasive is 50%, and the mass ratio of diamond to cubic boron nitride is 1:1 , the mass proportion of ceramic binder is 40%...

Embodiment 3

[0047] Composite grinding wheel for rail grinding, cuboid sintered blocks with a size of 60×30×15 mm, vitrified bond superabrasive sintered blocks 3, a total of 24 pieces, at an angular interval of 15°, distributed equiangularly over the entire circumference of the working layer of the grinding wheel, of which The rectangular surface of the sintered block with a size of 20 × 5 mm is the grinding surface. The diameter of the grinding wheel is 260 mm, the thickness is 60 mm, and the ring width of the grinding surface of the working layer is 50 mm. The composite grinding wheel is suitable for the model GMC-96X grinding train.

[0048] The specific production steps are as follows:

[0049](1) Weigh diamond, cubic boron nitride, ceramic bond and NaCl particles according to the mass ratio. The mass ratio of diamond and cubic boron nitride mixed abrasive is 30%, of which the mass ratio of diamond to cubic boron nitride is 1:1 , the mass ratio of vitrified binder is 50%, and the mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com