Online self-sharpening metallic bond and super-hard abrasive precision grinding pellet and preparation method thereof

A metal bond, super-hard abrasive technology, used in metal processing equipment, abrasives, grinding/polishing equipment, etc., can solve the problems of easy blockage of diamond abrasive tools, burnt surface of workpieces, low processing efficiency, etc., and achieve high brittleness, high The effect of reducing scrap rate and good processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

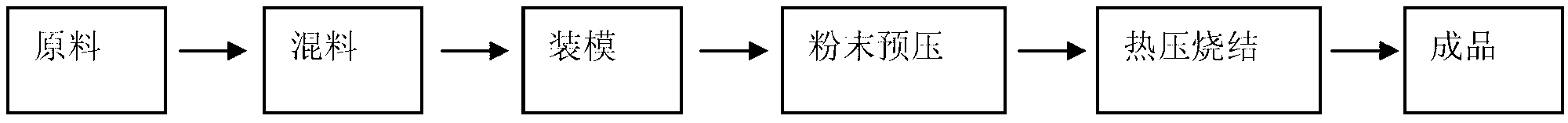

Method used

Image

Examples

Embodiment 1

[0029] Abrasive: Diamond particle size W50, 100% diamond concentration.

[0030] Binder: Copper powder with a mass percentage of 46%, tin powder with 33%, aluminum powder with 8% metal additives and electroplated copper-clad spherical graphite powder 12%, silica 0.6%, ferroferric oxide powder 0.4% non-metallic additives .

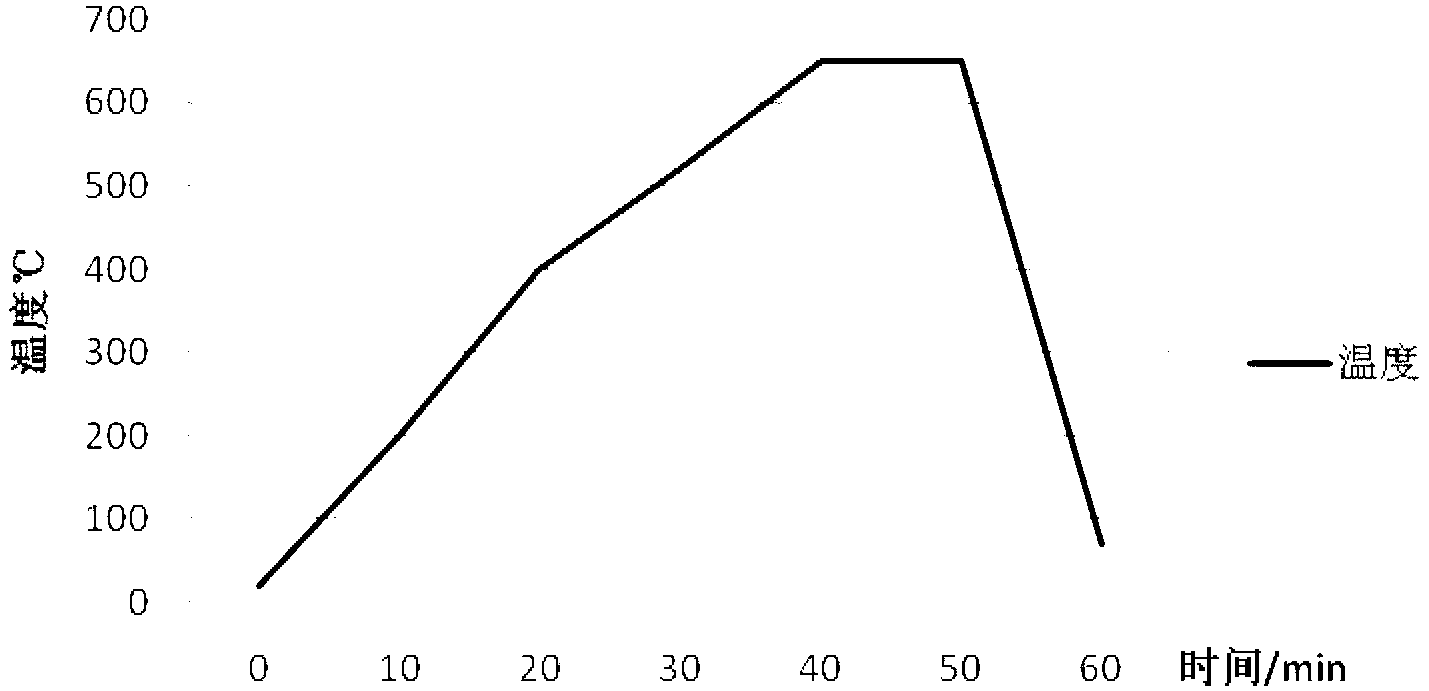

[0031] Sintering method: using the above-mentioned hot-pressing sintering process to make fine grinding discs.

Embodiment 2

[0033] Abrasive: diamond with particle size W10, 100% concentration.

[0034] Binder: copper powder mass percentage is 47.2%, tin powder 32.6%, aluminum powder 7.8% metal additives and electroplated copper-clad spherical graphite powder 11.7%, silicon dioxide 0.5%, ferroferric oxide powder 0.2% non-metallic additives .

[0035] Sintering method: using the above-mentioned hot-pressing sintering process to make fine grinding discs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com