Processing method of germanium single crystal non spherical surface optical element

A technology of optical components and processing methods, applied in metal processing equipment, manufacturing tools, turning equipment, etc., can solve the problems of high cost, difficult to guarantee accuracy, and long component cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

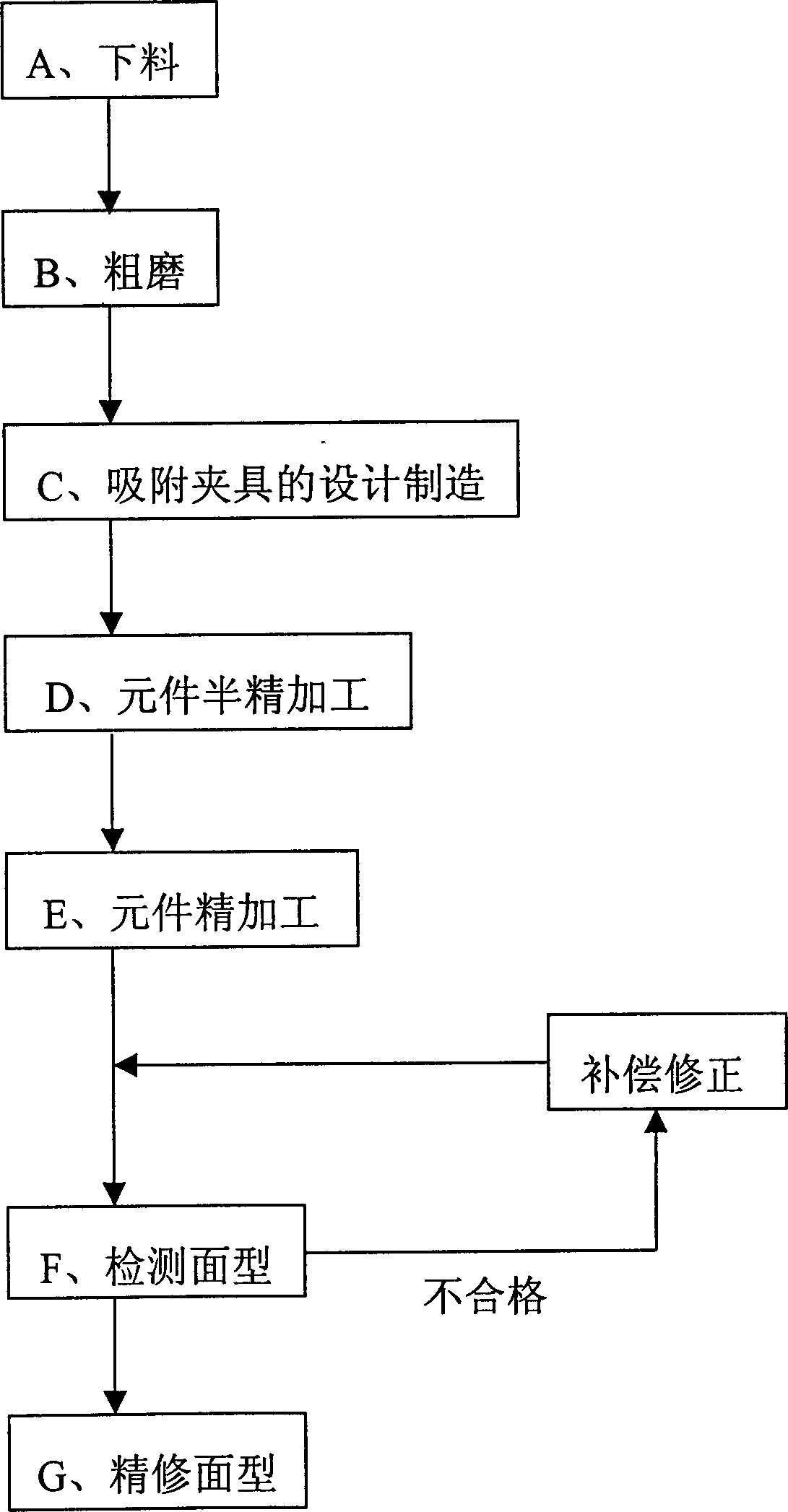

Method used

Image

Examples

Embodiment 2

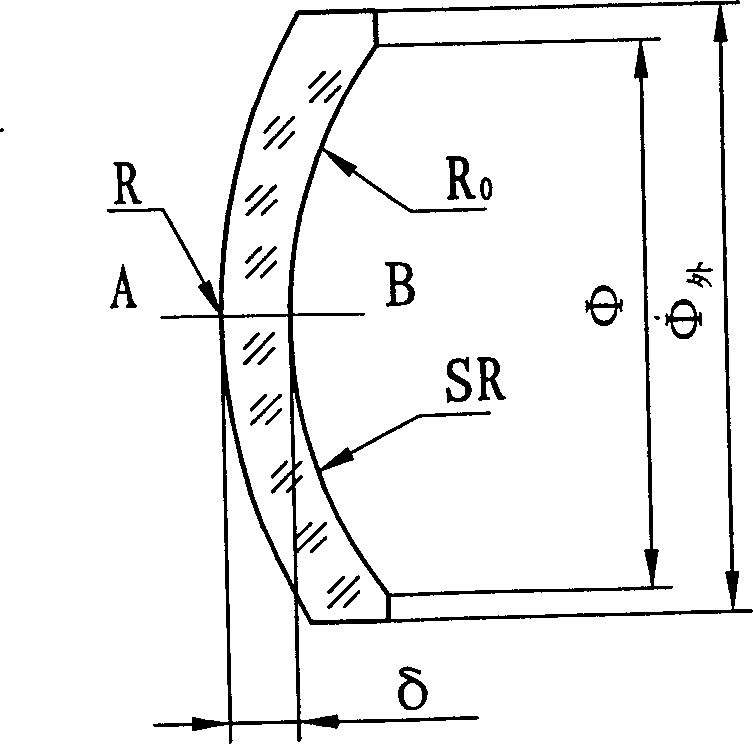

[0040] Embodiment two: process 10 times of aspheric elements, such as Figure 4 As shown, material: germanium single crystal, aspheric vertex radius R 0 =82.8769 mm, outer diameter Φ 外 =94±0.02 mm, effective radius of aspheric surface=Φ 外 / 2=94 / 2=47 mm, inner diameter Φ=87 mm, thickness δ=8.5±0.01 mm, aspheric equation: Y = C X 2 / 1 + [ 1 - ( 1 + K ) C 2 X 2 ] + A X 4 + B X 6 + D X 8 + E X 10 , Among them, Y represents ...

Embodiment 3

[0048] Embodiment three, process 15 times of aspheric elements, such as Figure 5 As shown, material: germanium single crystal, aspheric vertex radius R 0 =182.096, outer diameter Φ 外 =108±0.02 mm, effective radius of aspheric surface=Φ 外 / 2=108 / 2=54 mm, inner diameter Φ=96 mm, thickness δ=11.5±0.01 mm, aspheric equation: Y = CX 2 / 1 + [ 1 - ( 1 + K ) C 2 X 2 ] + A X 3 + BX 5 + CX 7 + EX 9 + FX 11 + GX ...

Embodiment 4

[0056] Embodiment four, process 20 times of aspherical elements, such as Image 6 As shown, material: germanium single crystal, where A surface is aspherical, R 0 =396.64 mm, outer diameter Φ=26±0.02 mm, effective radius of aspheric surface=Φ / 2=26 / 2=13 mm, central thickness δ=3±0.01 mm, 20th degree aspheric surface equation: Y = CX 2 / 1 + [ 1 - ( 1 + K ) C 2 X 2 ] + AX 4 + BX 6 + DX 8 . . + EX 10 + FX ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com