Methods of forming polycrystalline bodies using rhombohedral graphite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A. Definitions

[0021] In describing and claiming the present invention, the following terminology will be used.

[0022] The singular forms “a,”“an,” and “the” include plural referents unless the context clearly dictates otherwise. Thus, for example, reference to “a carbon source,” or “the carbon source,” includes reference to one or more specific sources of carbon, and reference to “an extraction process” includes reference to one or more of specific processes for extraction.

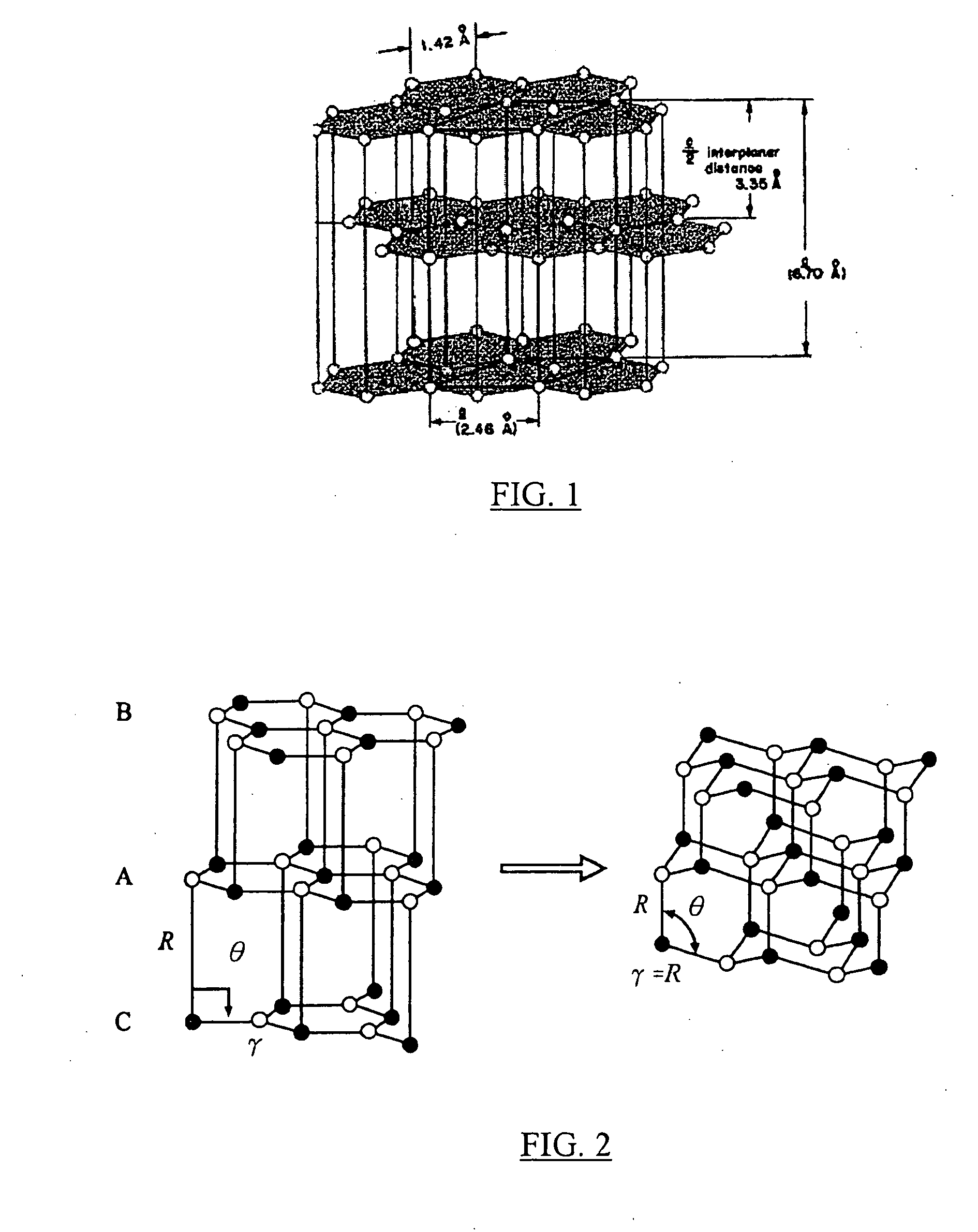

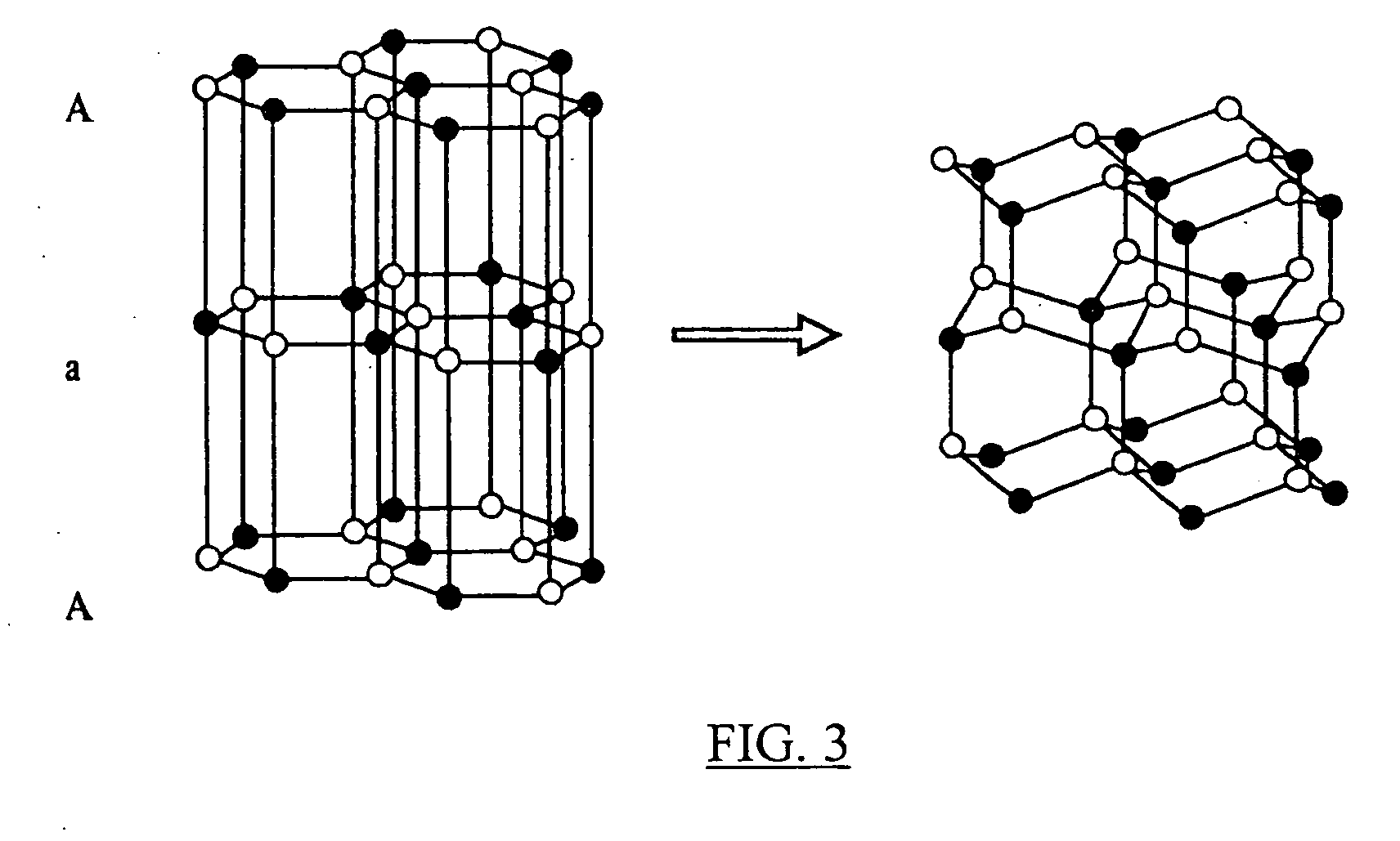

[0023] As used herein, “rhombohedral graphite,” and “rhombohedral polytype graphite” may be used interchangeably, and refer to an allotropic form of graphite with an ABCABC stacking sequence of graphene layers. Rhombohedral graphite is well known in the chemical arts and is contained in the IUPAC Copendium of Chemical Terminology (2nd ed. 1997), which is incorporated herein by reference.

[0024] As used herein, “hexagonal graphite,” and “2H graphite” may be used interchangeably, and refers to an allotropic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com