Wear-resistant diamond polishing grinder and production method thereof

A diamond and polishing grinding technology, which is applied in the direction of grinding/polishing equipment, abrasives, grinding devices, etc., can solve the problems of diamond polishing abrasives such as long time, large environmental pollution, and short service life, and achieves obvious toughening effect , low comprehensive cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

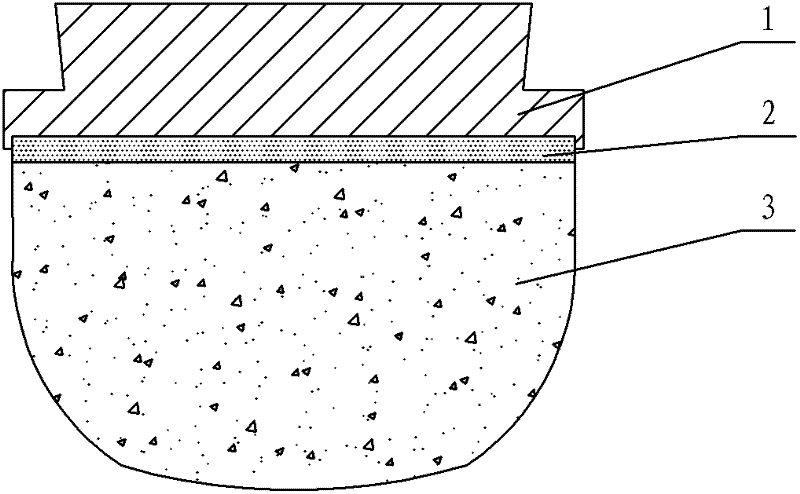

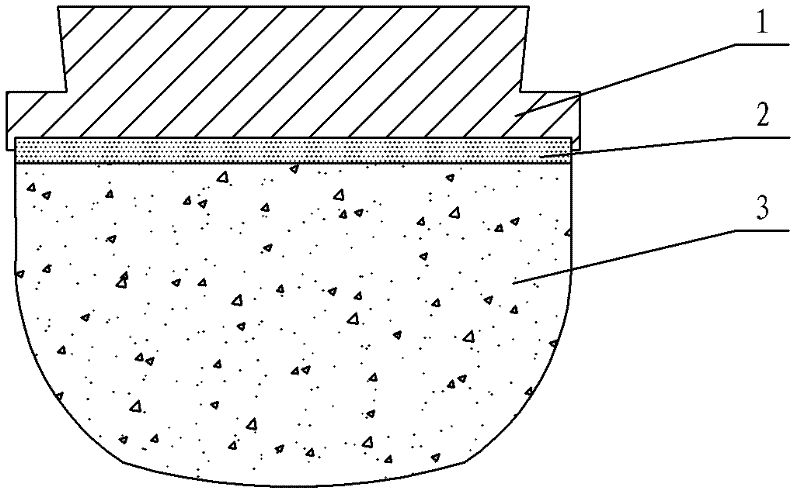

[0024] see figure 1 , the wear-resistant diamond polishing abrasive tool includes an abrasive layer 3 arranged on the deck 1, the abrasive layer is prepared from the following raw material components in volume percentage: 6.25% to 15% of diamond, 0% to 15% of silicon carbide, 200 35-60% of heat-resistant phenolic resin with fine mesh, 10-50% of carboxylated nitrile rubber with fine mesh of 40 mesh, 0.5-1% of zinc stearate, 0.5-5% of zinc oxide, 0-5% of sulfur, promoting Agent TMTD0~5%, stearic acid 0~5%.

[0025] The bonding agent in the abrasive layer is formed by adding carboxylated nitrile rubber to heat-resistant phenolic resin, and the volume ratio of heat-resistant phenolic resin to carboxylated nitrile rubber is 100:10-100.

[0026] The particle diameter of the diamond is 200 mesh to 8000 mesh, and the particle diameter of the silicon carbide is 200 mesh to 3000 mesh.

[0027] The deck 1 is made of plastic.

[0028] In this embodiment, the abrasive layer is prepared ...

no. 2 example

[0035] In this embodiment, the abrasive layer is prepared from the following raw material components in volume percentage: 400 mesh diamond 8%, 600 mesh silicon carbide 7%, phenolic resin powder 50%, carboxylated nitrile rubber 30%, zinc stearate 1%, zinc oxide 2%, sulfur 0.5%, accelerator TMTD 1%, stearic acid 0.5%.

[0036] See the first embodiment for the rest of the undescribed parts, and will not repeat them here.

no. 3 example

[0038] In this embodiment, the abrasive layer is prepared from the following raw material components in volume percentage: 800 mesh diamond 6.25%, 800 mesh silicon carbide 3.75%, phenolic resin powder 50%, carboxylated nitrile rubber 35%, zinc stearate 1%, zinc oxide 2%, sulfur 0.5%, accelerator TMTD 1%, stearic acid 0.5%.

[0039] See the first embodiment for the rest of the undescribed parts, and will not repeat them here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com