Intermetallic Aluminide Polycrystalline Diamond Compact (PDC) Cutting Elements

a technology of intermetallic aluminide and diamond compact, which is applied in the direction of manufacturing tools, other chemical processes, chemistry apparatus and processes, etc., can solve the problems that nickel aluminide may not experience such breakage of cutting surfaces, and achieves rapid dissipation of heat generated by friction, reduce the effect of differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

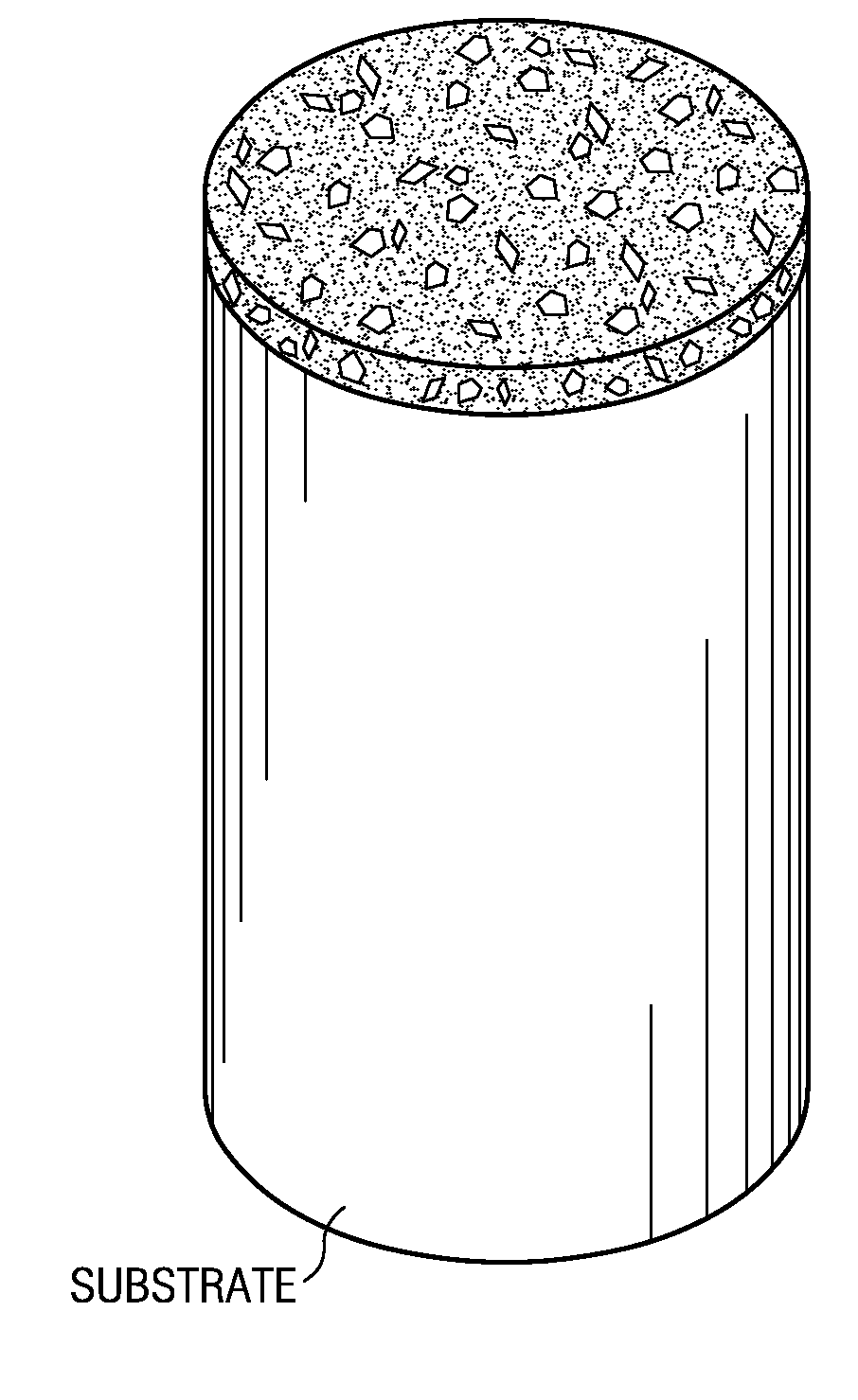

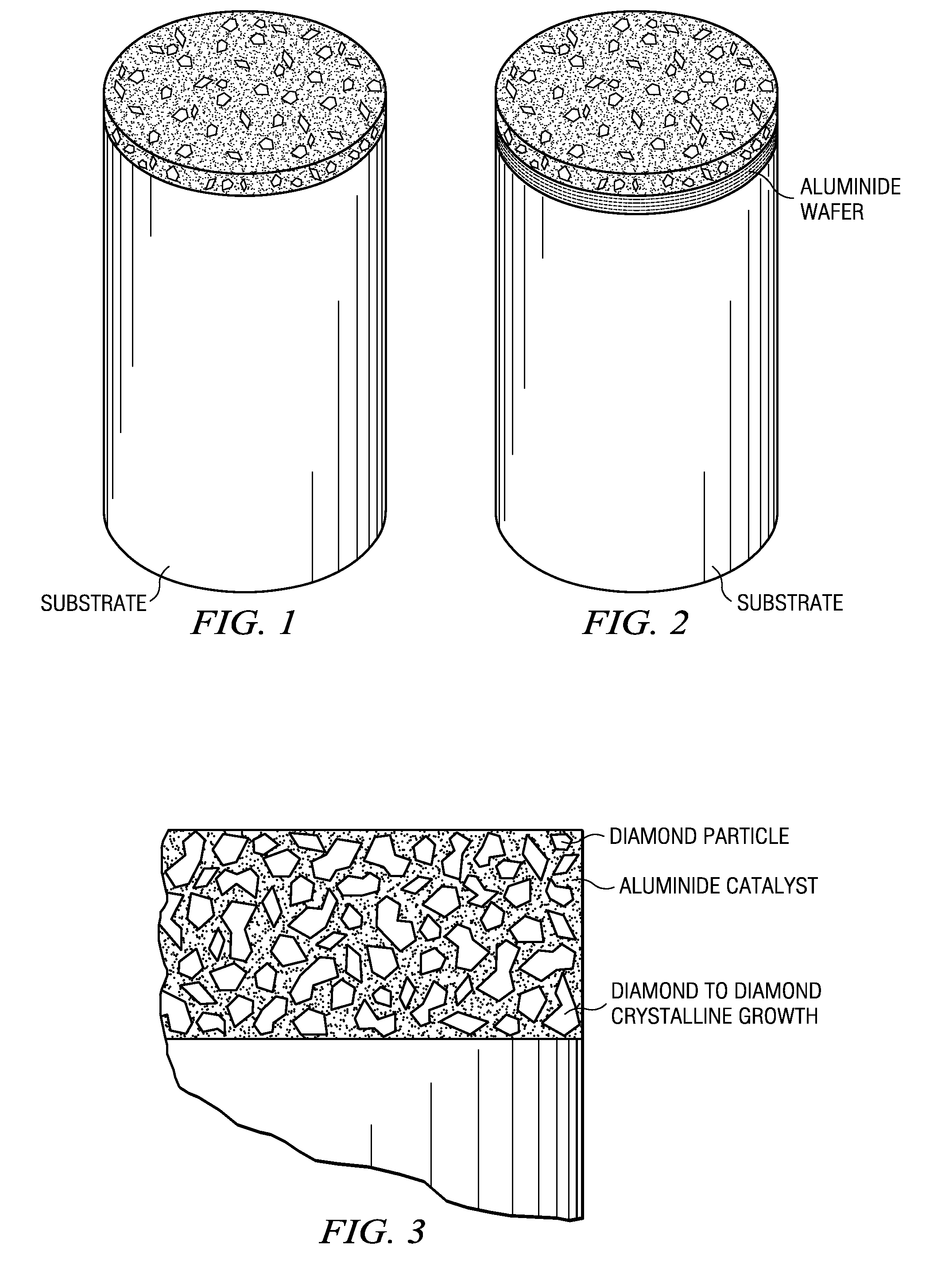

[0016]Preferred embodiments of the present disclosure and various advantages may be understood by referring to FIGS. 1, 2 and 3 of the drawings. Like numerals may be used for like and corresponding parts in the various drawings.

[0017]The terms “rotary drill bit” and “rotary drill bits” may be used in this application to include various types of roller cone drill bits, rotary cone drill bits, fixed cutter drill bits, drag bits, matrix drill bits and PDC drill bits operable to form a wellbore extending through one or more downhole formations. Rotary drill bits and associated components formed in accordance with teachings of the present disclosure may have many different designs and configurations. Cutting elements and blades incorporating features of the present disclosure may also be used with reamers, near bit reamers, and other downhole tools associated with forming a wellbore.

[0018]The terms “cutting element” and “cutting elements” may be used in this application to include variou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com