Method for preparing thermoelectric material of ternary diamond structure

A technology of thermoelectric materials and diamond, which is applied in the manufacture/processing of thermoelectric devices, materials for the junction leads of thermoelectric devices, thermoelectric devices that only use the Peltier or Seebeck effect, etc., can solve the problems that the thermoelectric properties of bulk materials have not been reported, etc. , to achieve the effect of high density, high feasibility and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

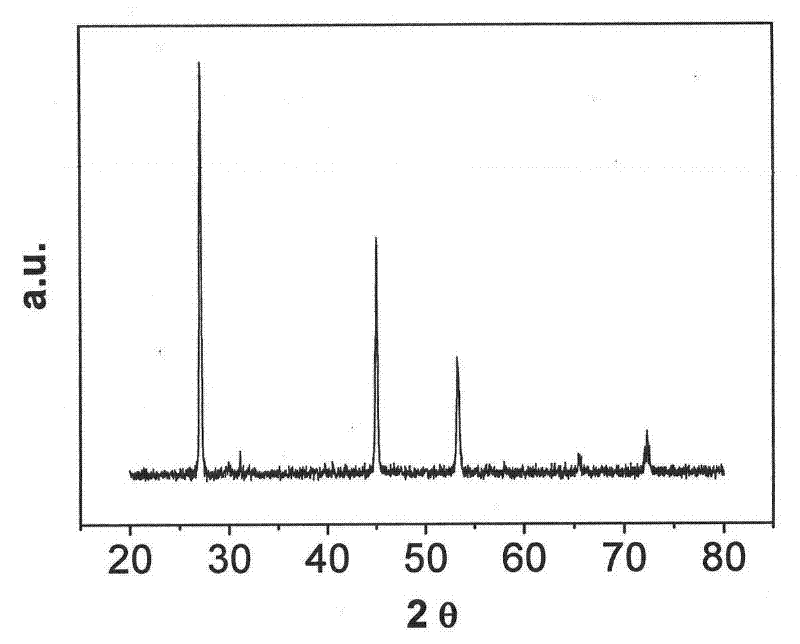

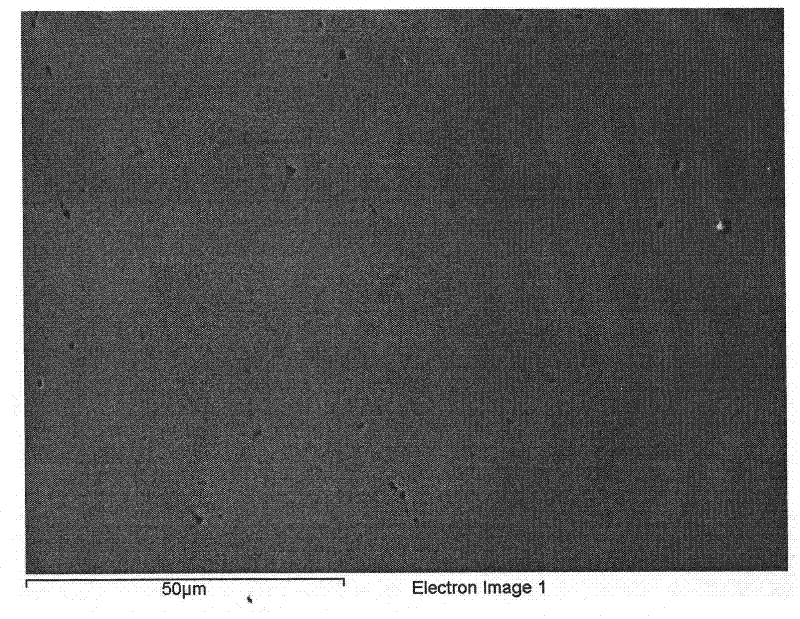

[0038] Cu powder (99.95%), Sn particles (99.999%) and Se particles (99.999%) are made of high-purity metal elemental raw materials according to Cu 2 SnSe 3 The stoichiometric ratio is weighed into a graphite crucible, and placed in a closed quartz glass tube, after vacuuming (less than 10 -2 Pa) Melt and seal with an oxygen-hydrogen flame, then slowly heat up the closed quartz glass tube containing the mixture to 900°C for melting, keep it warm for 24 hours, and then quench. The obtained sample (unopened tube) was directly annealed for 7 days at a temperature of 500°C. After the tube is opened, the sample is ground into powder, and SPS sintering is carried out at 530°C, the pressure is 60MPa, the heating rate is 50°C / min, and the holding time is 10 minutes.

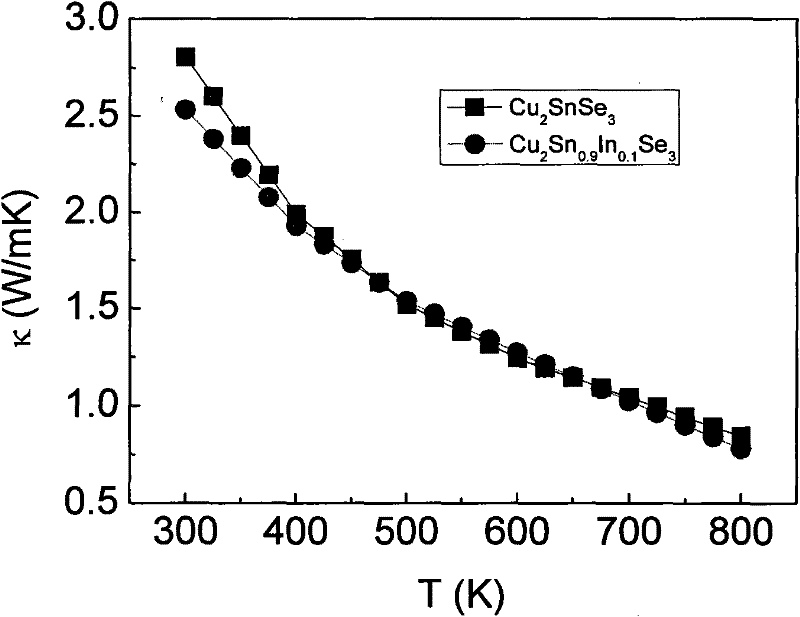

[0039] The thermal performance test shows that the material has very low thermal conductivity, especially at high temperature, when it reaches 800K, the thermal conductivity is 0.845W / mK, and the electrical conductivity...

Embodiment 2

[0041] Cu powder (99.95%), Sn grains (99.999%), In grains and Se grains (99.999%) are made of high-purity metal elemental raw materials according to Cu 2 sn 0.9 In 0.1 Se 3 The stoichiometric ratio is weighed into a graphite crucible, and placed in a closed quartz glass tube, after vacuuming (less than 10 -2 Pa) Melt and seal with an oxygen-hydrogen flame, then slowly heat up the closed quartz glass tube containing the mixture to 900°C for melting, keep it warm for 24 hours, and then quench. The obtained sample (unopened tube) was directly annealed for 7 days at a temperature of 500°C. After the tube is opened, the sample is ground into powder, and SPS sintering is carried out at 530°C, the pressure is 60MPa, the heating rate is 50°C / min, and the holding time is 5 minutes.

[0042] The thermal performance test shows that the material also has a very low thermal conductivity after doping low-valence metal In at the B site (Sn), which is 0.7W / mK at 800K, and the electrical c...

Embodiment 6

[0047] Cu powder (99.95%), Sn grains (99.999%), Bi powder (99.999%) and Se grains (99.999%) are prepared according to Cu 2 SnSe 2.55 Bi 0.45 The stoichiometric ratio is weighed into a graphite crucible, and placed in a closed quartz glass tube, after vacuuming (less than 10 -2 Pa) Melt and seal with an oxygen-hydrogen flame, then slowly heat up the closed quartz glass tube containing the mixture to 1000°C for melting, and keep it at 1000°C for 48 hours before quenching. The obtained sample (unopened tube) was directly annealed in a muffle furnace for 240 h at a temperature of 600 °C. After the tube is opened, the sample is ground into powder, and SPS sintering is carried out at 500°C, the pressure is 50MPa, the heating rate is 60°C / min, and the holding time is 10 minutes.

[0048] Thermal performance tests show that the material has excellent thermoelectric properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Conductivity at room temperature | aaaaa | aaaaa |

| Seebeck coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com