Semiconductor element for thermoelectric module of real-time fluorescent quantitative PCR instrument

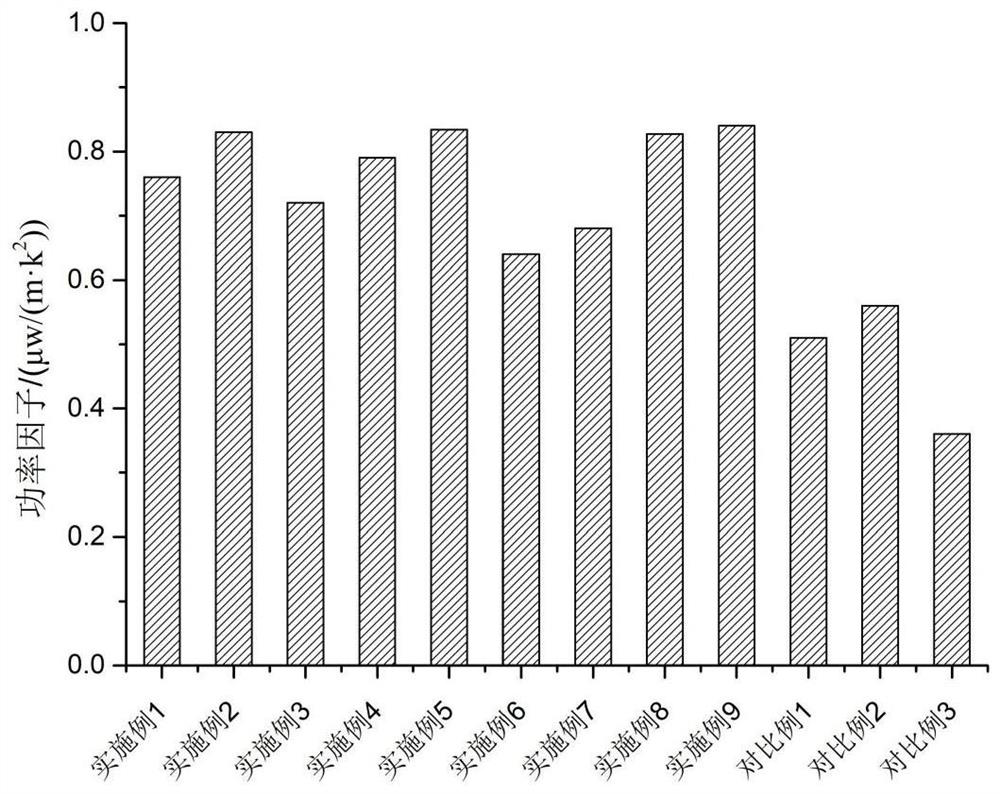

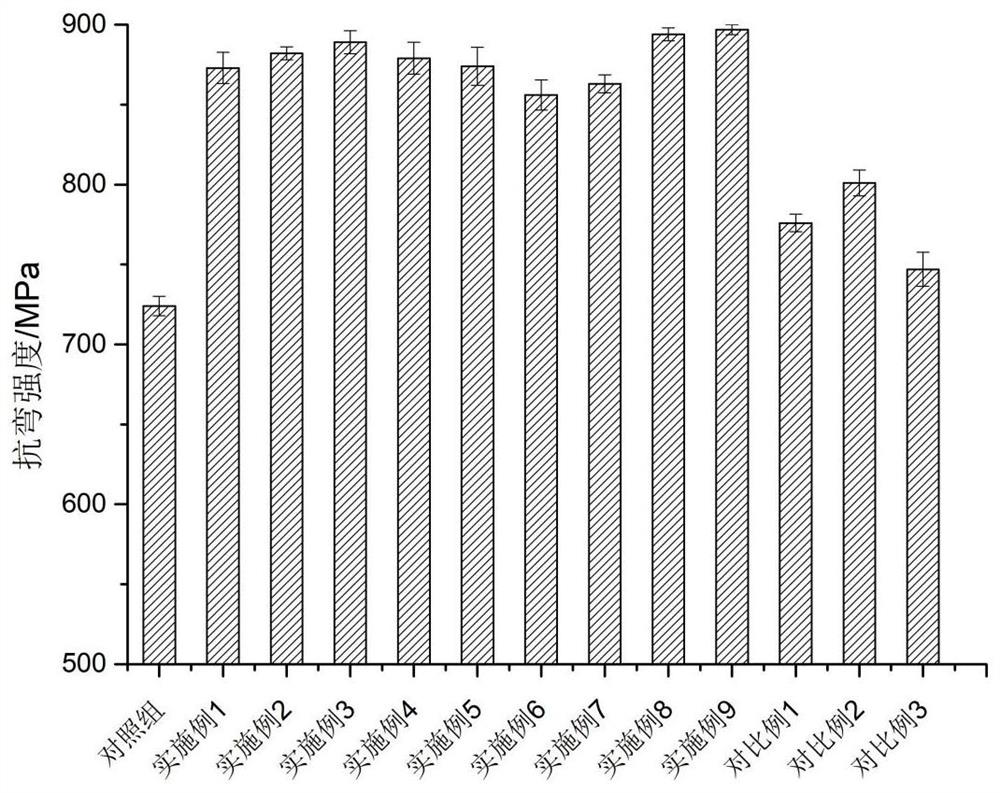

A semiconductor and component technology, which is applied in the field of semiconductor components for thermoelectric modules of real-time fluorescent quantitative PCR instruments, can solve problems such as potential difference increase, and achieve good thermoelectric conversion, high bending strength, and excellent thermoelectric performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] In some embodiments of the present invention, a method for preparing a semiconductor element includes the following steps:

[0034] In parts by weight, the SnCl 2 2H 2 O is dissolved in 100-150 parts by weight of absolute ethanol to make Sn 2+ The concentration is 0.25~75mol / L, reflux at 85~100℃ for 10~14h, and then press Sn 4+ :Sr 2+ :M 4+ = 1-a-b:2a:b ratio to add SrCl 2 ·6H 2 O, MCl 4 , wherein, 0.1≤a<0.3, 0.2≤b<0.5; metal M is one of Ti, Zr, Hf, continue to reflux at 85~100°C for 10~14h, and age at 30~35°C for 22~ 28h, obtain sol;

[0035] Using the dipping-lifting process, wash the ceramic substrate with 10% dilute hydrochloric acid, distilled water, and absolute ethanol in sequence, dry it at 45-55°C for 2-3 hours, and then dip it in the above sol for 1-3 minutes, vertically Steady pulling for 3 to 6 times, then drying at 75 to 100°C for 20 to 30 minutes, and then heat treatment at 550 to 650°C for 2 to 4 hours to obtain a nanoparticle film;

[0036] Dil...

Embodiment 1

[0041] A method for preparing a semiconductor element, comprising the steps of:

[0042]In parts by weight, the SnCl 2 2H 2 O is dissolved in 120 parts by weight of absolute ethanol to make Sn 2+ The concentration is 0.45mol / L, reflux at 90°C for 10h, and then press Sn 4+ :Sr 2+ :Hf 4+ =0.6:0.2:0.3 ratio to add SrCl 2 ·6H 2 O, HfCl 4 , continue to reflux at 90°C for 12h, and age at 30°C for 24h to obtain a sol;

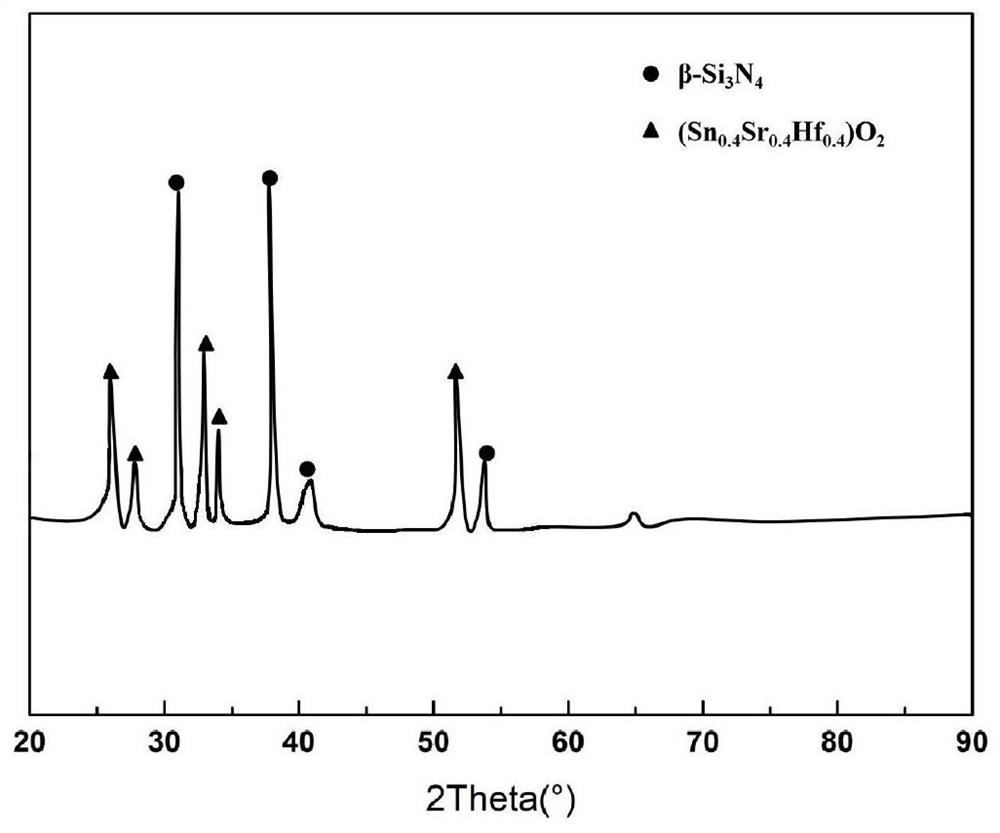

[0043] Using the immersion-lifting process, the β-silicon nitride ceramic substrate with a size of 20mm×10mm×4mm was washed with 10% dilute hydrochloric acid, distilled water, and absolute ethanol in sequence, dried at 45°C for 3 hours, and then dipped After 1 min of the above sol, it was pulled vertically and steadily for 5 times, then dried at 85 °C for 20 min, and then heat-treated at 550 °C for 4 h to obtain (Sn 0.6 Sr 0.2 f 0.3 )O 2 nanoparticle film;

[0044] Dilute the silver paste according to the weight ratio of silver paste and turpentine oil to...

Embodiment 2

[0046] A method for preparing a semiconductor element, comprising the steps of:

[0047] In parts by weight, the SnCl 2 2H 2 O is dissolved in 140 parts by weight of absolute ethanol to make Sn 2+ The concentration is 0.65mol / L, reflux at 100°C for 12h, and then press Sn 4+ :Sr 2+ :Hf 4+ =0.4:0.4:0.4 ratio to add SrCl 2 ·6H 2 O, HfCl 4 , continue to reflux at 100°C for 12h, and age at 32°C for 26h to obtain a sol;

[0048] Using the dipping-lifting process, the β-silicon nitride ceramic substrate with a size of 20mm×10mm×4mm was washed with 10% dilute hydrochloric acid, distilled water and absolute ethanol in sequence, dried at 50°C for 2.5h, and then After dipping in the above sol for 2 min, it was pulled vertically and steadily for 4 times, then dried at 90 °C for 25 min, and then heat-treated at 600 °C for 3 h to obtain (Sn 0.4 Sr 0.4 f 0.4 )O 2 nanoparticle film;

[0049] Dilute the silver paste according to the weight ratio of silver paste to turpentine oil a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com