Composite thermoelectric material and preparation method thereof

A technology of thermoelectric material and composite powder, which is applied in the direction of lead wire material of thermoelectric device and the manufacture/processing of thermoelectric device. It can solve the problems of high cost, complicated process and environmental pollution, and achieve good thermoelectric performance and broad market prospect. , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

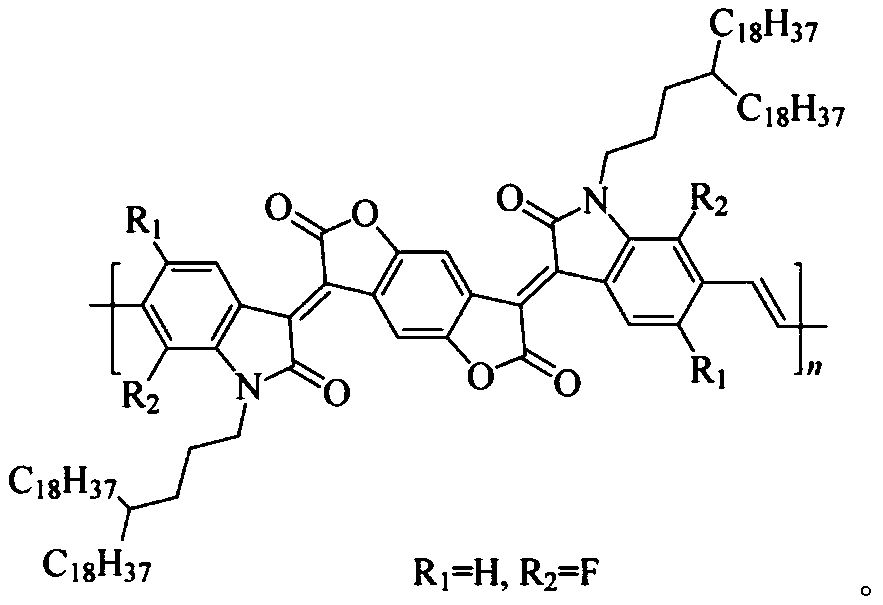

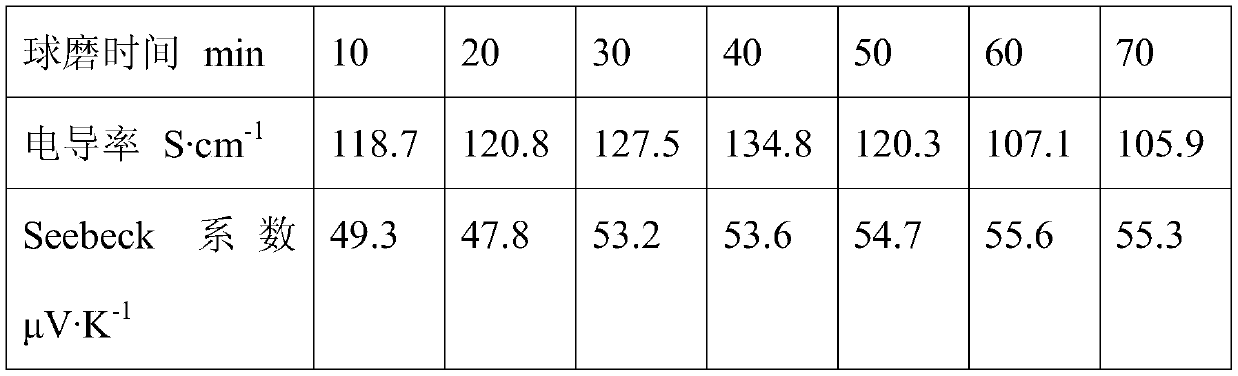

[0051] (1) Ingredients: First, 20.0 g of zirconia balls with a diameter of 2 mm and 0.6 g of MWCNT (commercially available carbon nanotubes) were added to a zirconia ball mill jar with a volume of 100 mL. After mixing evenly, 2 g of FBDPPV polymer was added. After sealing the ball mill jar, put it into a ball mill for ball milling.

[0052] (2) Ball milling: start the ball mill, and set the ball milling process parameters, the ball milling process parameters are as follows: firstly adjust the rotating speed to 150rpm for 40min; then adjust the rotating speed to 550rpm for 5min.

[0053] (3) Centrifugation and washing: after ball milling, transfer the balls and products in the ball mill pot to a beaker, add deionized water and stir, then use tweezers to take out the zirconia balls from the beaker, and then remove the zirconia balls from the beaker. The black product was washed with deionized water and centrifuged, and the washing and centrifugation steps were repeated until the...

Embodiment 2

[0064] (1) Ingredients: First, add 30g of zirconia balls with a diameter of 2mm and 0.6g of MWCNT into a zirconia ball mill with a volume of 100mL. After mixing evenly, add 4g of FBDPPV polymer, seal the ball mill and put it into a ball mill ball milling.

[0065] (2) Ball milling: start the ball mill, and set the ball milling process parameters. The ball milling process parameters are as follows: first adjust the speed to 150 rpm for 50 minutes, then adjust the speed to 550 rpm for 10 minutes.

[0066] (3) Centrifugation and washing: After ball milling, transfer the balls and products in the ball mill pot to a beaker, add deionized water and stir, then use tweezers to take out the zirconia balls from the beaker, and then clean the black balls in the beaker. The product was washed with deionized water and centrifuged, and the washing and centrifugation steps were repeated until the upper layer solution in the centrifuge tube was colorless.

[0067] (4) Drying: put the centrif...

Embodiment 3

[0070] (1) Ingredients: First, add 20g of zirconia balls with a diameter of 2mm and 0.8g of MWCNT into a zirconia ball mill with a volume of 100mL. After mixing evenly, add 2g of FBDPPV polymer, seal the ball mill and put it into a ball mill ball milling.

[0071] (2) Ball milling: turn on the ball mill, and set the ball milling process parameters. The ball milling process parameters are as follows: first adjust the speed to 300 rpm for 40 minutes, then adjust the speed to 750 rpm for 15 minutes.

[0072] (3) Centrifugation and washing: after ball milling, transfer the balls and products in the ball mill tank to a beaker, add deionized water and stir, then use tweezers to take out the zirconia balls from the beaker, and then remove the zirconia balls from the beaker. The black product was washed with deionized water and centrifuged, and the washing and centrifugation steps were repeated until the upper layer solution in the centrifuge tube was colorless.

[0073] (4) Drying: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com