Thermoelectric conversion material, and thermoelectric conversion element prepared therewith

A technology of thermoelectric conversion and conductive materials, applied in electrical components, thermoelectric device junction lead-out materials, electric solid devices, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

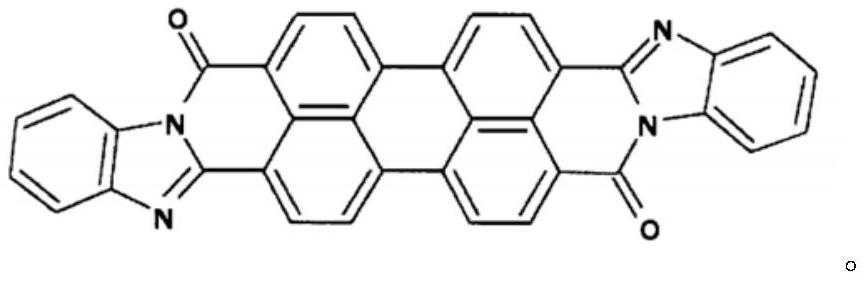

[0094] The thermoelectric conversion material of the present embodiment includes a conductive material (A) and an organic compound (B) having a small |(HOMO of the organic compound (B))-(HOMO of the conductive material (A))| (hereinafter also referred to as ΔHOMO). . Through this specific combination, high Seebeck coefficient and electrical conductivity can coexist, and excellent thermoelectric performance can be exerted. The reason for this is that holes (carriers) efficiently move from an organic compound having low thermal excitation energy to a conductive material, and the holes move in the conductive material, thereby realizing high Seebeck coefficient and conductivity.

[0095]

[0096] The conductive material (A) contributes to enhancement of conductivity. The conductivity can be improved by increasing the content of the conductive material (A).

[0097] The conductive material (A) is not particularly limited as long as it is a conductive material (carbon material, ...

no. 2 approach

[0368] All the thermoelectric conversion materials of this embodiment satisfy the following (1) to (3).

[0369] (1) 0<((HOMO of organic compound (B))-(HOMO of conductive material (A))×((HOMO of organic compound (C))-(HOMO of conductive material (A)))

[0370] (2) |(HOMO of organic compound (B))-(HOMO of conductive material (A))|<|(HOMO of organic compound (C))-(HOMO of conductive material (A))|

[0371] (3) The adsorptivity of the organic compound (B) to the conductive material (A) is greater than the adsorptivity of the organic compound (C) to the conductive material (A).

[0372] Through this specific combination, high Seebeck coefficient and electrical conductivity can coexist, and excellent thermoelectric performance can be exerted. The reason for this is that holes (carriers) efficiently move from an organic compound having low thermal excitation energy to a conductive material, and the holes move in the conductive material, thereby realizing high Seebeck coefficient an...

Embodiment

[0393] Hereinafter, the present invention will be described in more detail through experimental examples. In addition, hereinafter, "part" means "mass part", and "%" means "mass %". In addition, NMP represents N-methyl pyrrolidone (N-methyl pyrrolidone).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com