Cu-Ni thin film material for temperature sensing and preparation method of Cu-Ni thin film material

A kind of thin film material, cu-ni technology, applied in metal material coating process, vacuum evaporation plating, coating, etc., can solve problems such as difficult and precise regulation, and achieve temperature sensitivity improvement, precise size control, and excellent thermoelectric performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: The present invention provides a method for preparing a Cu70Ni30 thin film material for temperature sensing, comprising the following steps:

[0039] Cu-Ni thin films were deposited on Si-based substrates by high-vacuum magnetron sputtering double-target co-deposition.

[0040] The method for depositing a Cu-Ni thin film on a substrate includes: placing a Cu target and a Ni target with polished surfaces on two sputtering target positions of a high-vacuum magnetron sputtering system, wherein the Cu target is connected to a radio frequency power supply, and the Ni target is connected to a radio frequency power supply. Connect the DC power supply; fix the substrate on the sample stage of the magnetron sputtering equipment, and the distance between the substrate and the target is 50-90mm. Close the magnetron sputtering reaction chamber and perform vacuum pumping; the vacuum degree of the sputtering chamber is not less than 1×10 -4 Pa, pass argon gas at a flow...

Embodiment 2

[0041] Embodiment 2: The present invention provides a method for preparing a Cu70Ni30 thin film material for temperature sensing, comprising the following steps:

[0042] Cu-Ni thin films were deposited on Si-based substrates by high-vacuum magnetron sputtering double-target co-deposition.

[0043]The method for depositing a Cu-Ni thin film on a substrate includes: placing a Cu target and a Ni target with polished surfaces on two sputtering target positions of a high-vacuum magnetron sputtering system, wherein the Cu target is connected to a radio frequency power supply, and the Ni target is connected to a radio frequency power supply. Connect the DC power supply; fix the substrate on the sample stage of the magnetron sputtering equipment, and the distance between the substrate and the target is 50-90mm. Close the magnetron sputtering reaction chamber and carry out the vacuum pumping operation; the vacuum degree of the sputtering chamber is not less than 1×10 -4 Pa, pass argo...

Embodiment 3

[0044] Embodiment 3: The present invention provides a method for preparing a Cu70Ni30 thin film material for temperature sensing, comprising the following steps:

[0045] (1) Using high vacuum magnetron sputtering double target co-deposition to deposit Cu-Ni thin film on Si-based substrate;

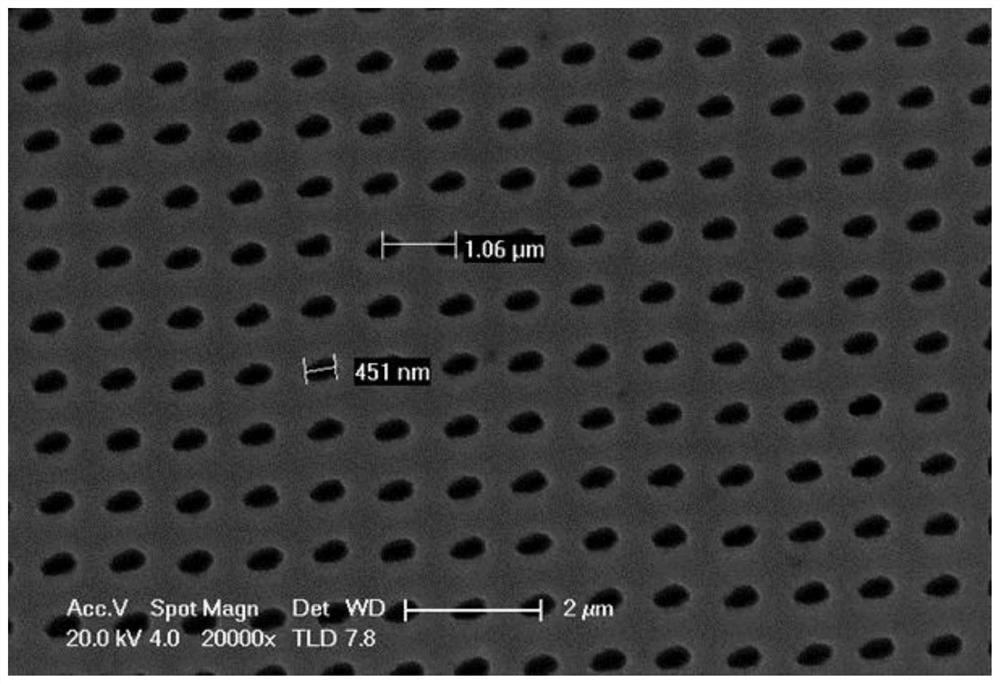

[0046] (2) A hole array is etched on the Cu-Ni film by electron beam exposure.

[0047] In this example, step (1) includes: placing the polished Cu target and Ni target on the two sputtering target positions of the high vacuum magnetron sputtering system, wherein the Cu target is connected to the radio frequency power supply, and the Ni target is connected to the DC power supply ; Fix the substrate on the sample stage of the magnetron sputtering equipment, and the distance between the substrate and the target is 50-90mm. Close the magnetron sputtering reaction chamber and carry out the vacuum pumping operation; the vacuum degree of the sputtering chamber is not less than 1×10 -4 Pa, pas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com