Cyclone separation dust cup of dust collector

A cyclone separation and cyclone separator technology, applied in suction filters and other directions, can solve the problems of increased secondary separation workload, affecting the cyclone separation effect, dust entry, etc., to improve the cyclone separation efficiency, the overall structure is reasonable and practical, and the cyclone is good. separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

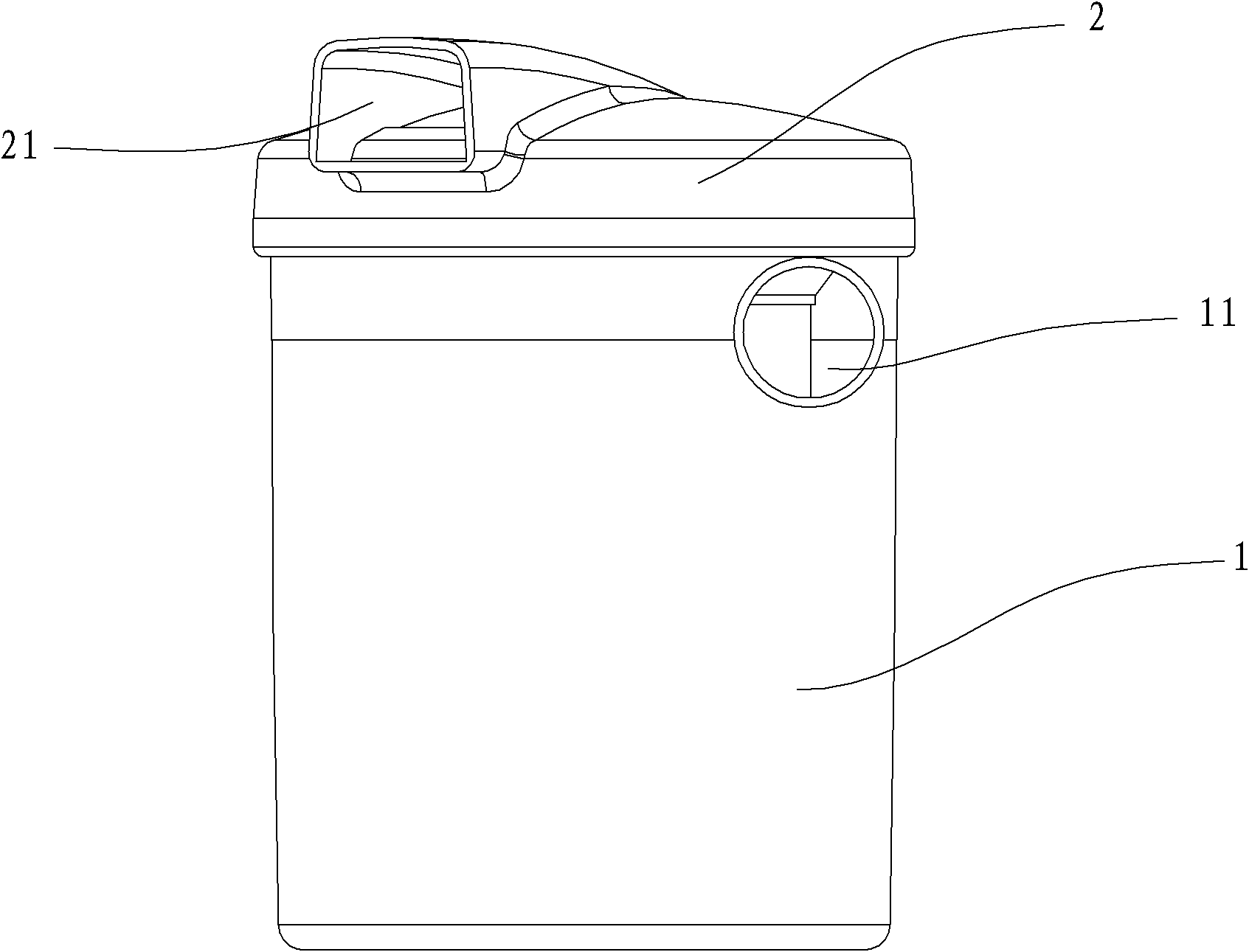

[0025] see figure 1 , a cyclone-separated dust cup for a vacuum cleaner, comprising a cylindrical cup body 1 and a dust cup cover 2, wherein the upper end of the side wall of the cup body 1 is provided with a tangential first-stage air inlet 11, and the dust cup cover 2 is provided with Air outlet 21.

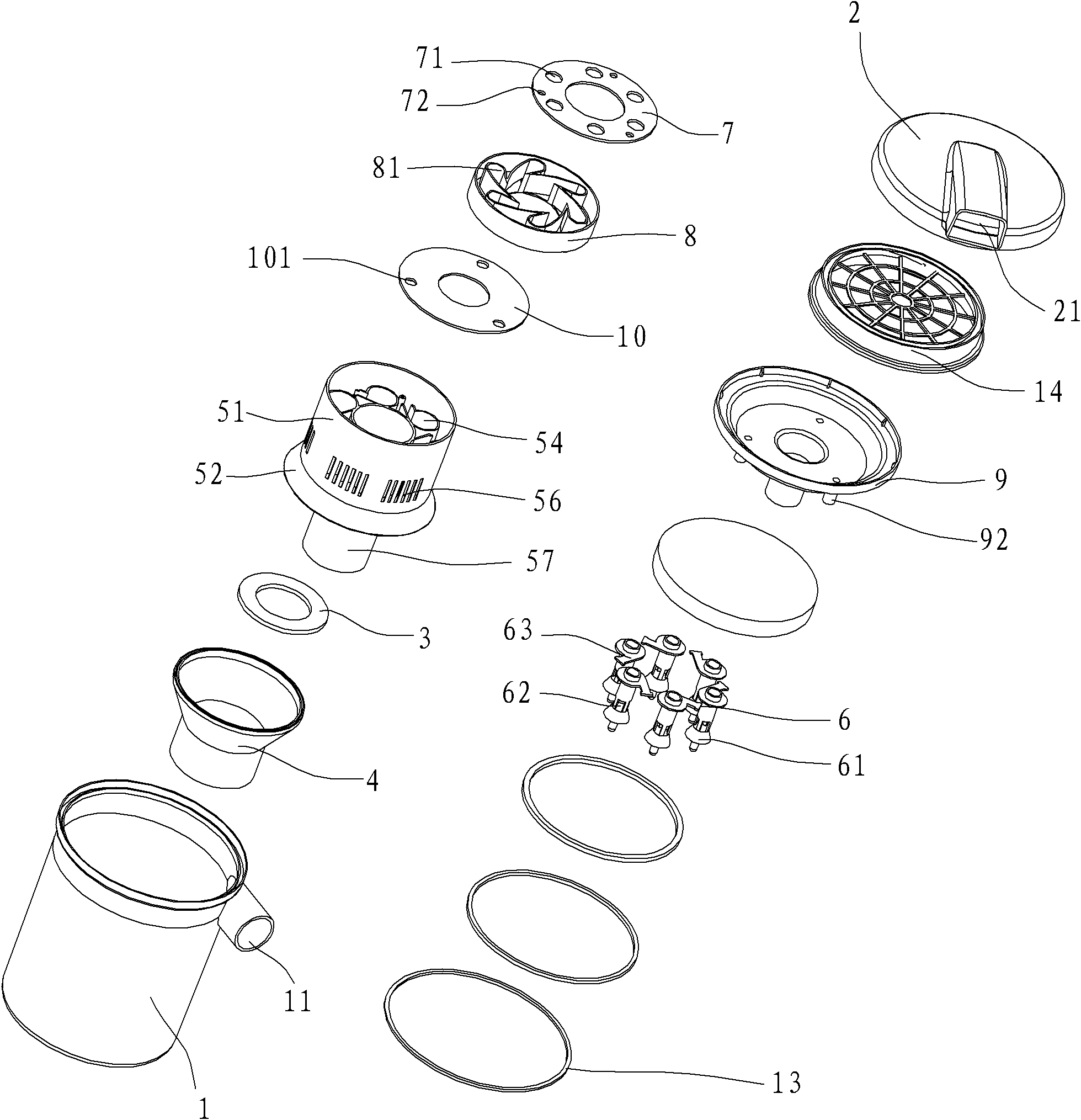

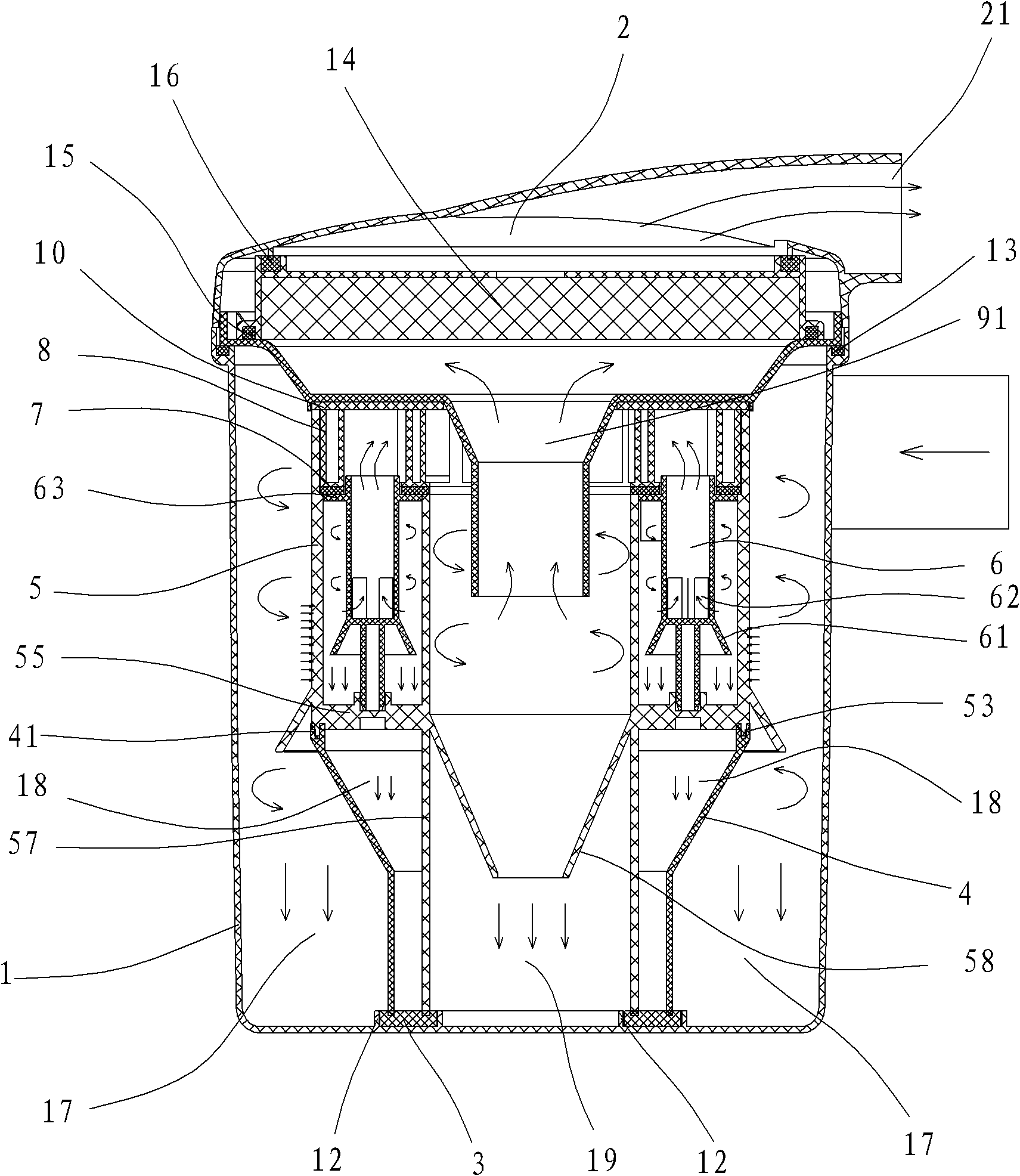

[0026] see figure 2 and image 3 The bottom wall of the cup body 1 is provided with two circular convex ribs 12, the dust collection chamber gasket 3 is inserted between the two convex ribs 12, and the distance between the two convex ribs 12 is the same as that of the dust collection chamber gasket 3 to match the width. The lower wall 4 of the cyclone separator is fixed on the outer part of the gasket 3 of the dust collection chamber. The lower wall 4 of the cyclone separator has two parts, the upper part is in the shape of an inverted fru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com