An intermittent cyclone separation device

A cyclone separation device and intermittent technology, which are applied in separation methods, liquid separation, chemical instruments and methods, etc., can solve the problems of small oil core diameter and reduce cyclone separation efficiency, etc., and achieve low cost, improved efficiency, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

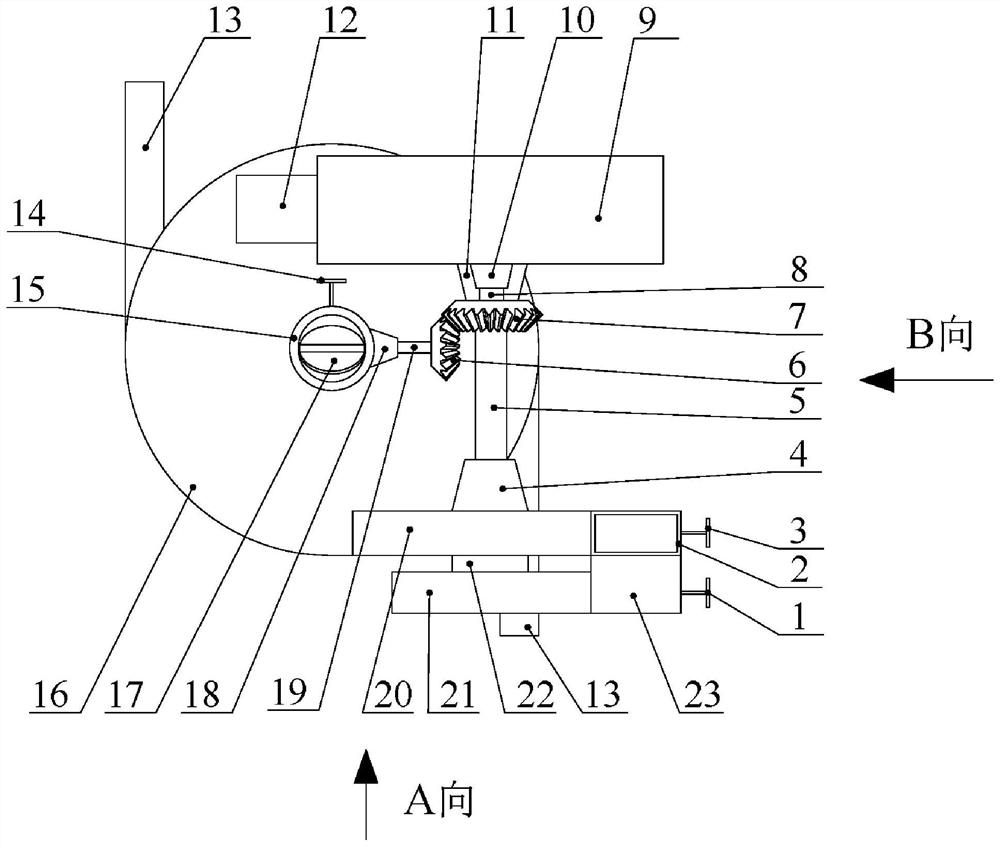

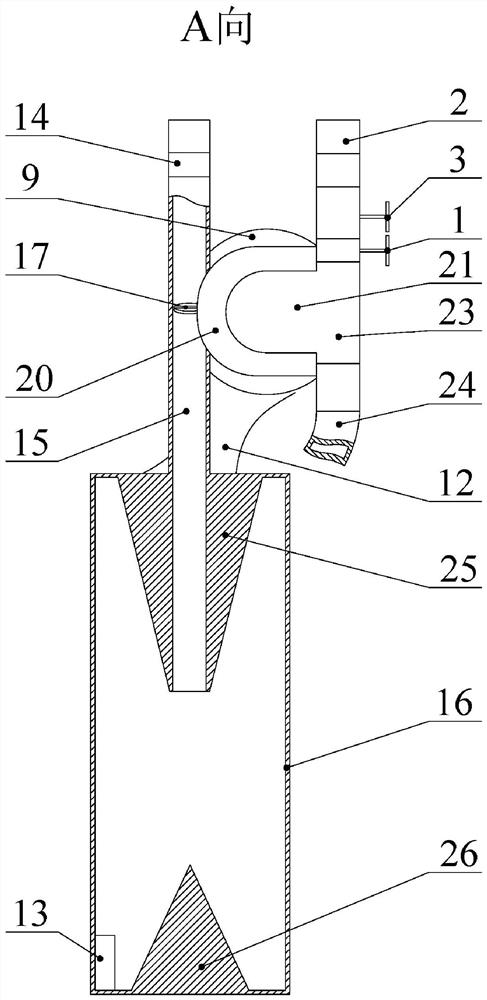

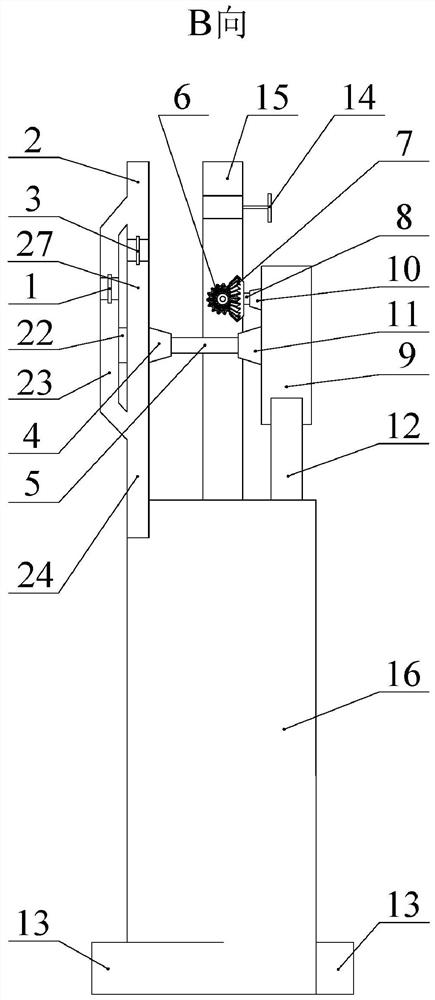

[0032] The present invention will be further described below in conjunction with accompanying drawing:

[0033] Such as Figure 1 to Figure 13 As shown, a high-efficiency gap type cyclone separation device according to the embodiment of the present invention includes a bypass pipe valve 1, an aqueous phase outlet pipe 2, a rotational speed regulating pipe valve 3, an impeller sealing structure 4, an impeller shaft 5, and a small bevel gear 6 , large bevel gear 7, large bevel gear shaft 8, intermittent rotation mechanism housing 9, large bevel gear shaft sealing structure 10, intermittent mechanism sealing structure 11, fixed structure 12, tangential inlet 13, oil phase outlet pipe valve 14, oil Phase outlet pipe 15, swirl chamber 16, oil phase baffle 17, small bevel gear shaft sealing structure 18, small bevel gear shaft 19, impeller housing 20, cam chamber 21, shaft sleeve 22, bypass pipe 23, cutting To the outlet 24, the outlet cone 25, the inlet cone 26, the rotating speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com